To achieve high income, how should manganese extraction process?

1. Manganese ore’s value

①90% to 95% of manganese ore is used in the iron and steel industry, mainly used as deoxidizer and desulfurizer in iron making, steel making and alloy manufacturing.

②10%~5% of manganese is used in other industrial fields, such as the chemical industry (manufacturing of various manganese salts), light industry (for batteries, matches, printing paints, soap making, etc.), building materials industry (coloring of glass and ceramics) In short, manganese has a very important strategic position in the national economy.

2. Manganese ore types

①One of the most important industries is the iron and steel industry, which accounts for 90% to 95% of the total. It is mainly used as a deoxidizer and desulfurizer in ironmaking, steelmaking, and alloy manufacturing.

②Classified by the natural type of minerals: oxide minerals, carbonate minerals, sulfide minerals, silicate minerals, borate minerals

③ According to the industrial use of manganese ore: manganese ore for metallurgy, manganese ore for the chemical industry.

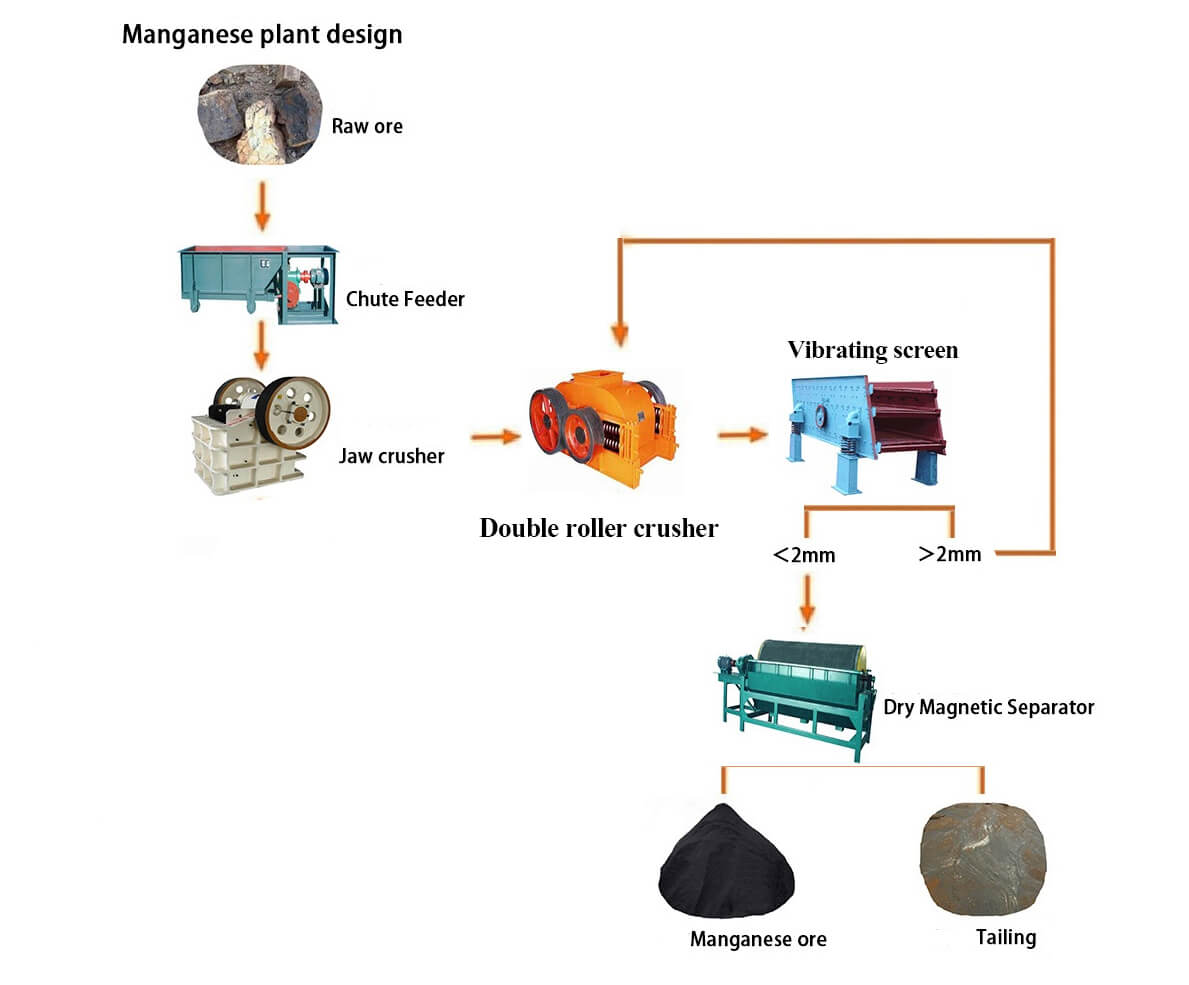

3. Manganese extraction process

The manganese extraction process is designed according to the properties of manganese ore, which can effectively improve the selected grade of manganese ore and improve the utilization value of manganese ore. Common manganese beneficiation methods include mechanical beneficiation (washing, screening, gravity separation, strong magnetic separation, flotation), pyro-enrichment, chemical beneficiation, etc. Choose the appropriate mineral processing process according to the specific minerals.

①Manganese carbonate ore is mostly washed, and the vibrating screen is used to spray water. The product on the screen is washed ore, and the product under the screen is spirally classified, and the returned sand is combined with the product on the screen.

② Gravity separation is carried out according to the density and particle size of various minerals, such as hard manganese ore, pyrolusite, and limonite. fine-grained materials) and drum separators, cyclones, vibrating chutes, etc. using heavy media.

③Magnetic separation is a beneficiation method that separates different minerals according to the magnetic difference between minerals. Manganese ore has weak magnetic properties, and the strong magnetic separation process is adopted. The process is simple, the operation is convenient, and the recovery efficiency is high.

④For the flotation of manganese ore, forward and reverse flotation can be used, usually anion positive flotation and cation reverse flotation are commonly used.

Mineral beneficiation is an important part of many mineral products. Therefore, it is necessary to be cautious in the selection of mineral processing equipment and beneficiation process. On the basis of mineral processing experiments, comprehensive understanding and analysis of minerals, design of mineral processing process flow, and selection of suitable mineral processing equipment. Only with its own beneficiation equipment can it achieve the beneficiation effect and realize the utilization value of minerals.