Description

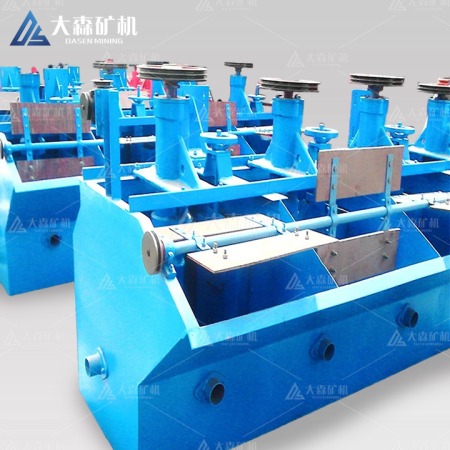

Name: SF flotation machine, froth flotation machine, SF Series Froth Cell

Uses: beneficiation, mineral selection, copper, gold

Feed particle size: 1-2mm

Processing capacity: 2-100T/H

Single tank volume: 0.37-20 tons / tank

Power: 1.5-45kw

The SF froth flotation machine is a versatile tool for separating minerals from a variety of materials, including non-ferrous and ferrous metals, non-metallic minerals, and chemical raw materials. Renowned for its high suction capacity and energy efficiency, the machine incorporates three core functions within its cells: air intake, pulp intake, and flotation. Unlike traditional flotation systems, it requires no auxiliary equipment, simplifying the flotation process. The horizontal configuration facilitates operational adjustments, while the optimized slurry circulation effectively minimizes coarse sand sedimentation.

The SF series froth cell is a high-efficiency mineral processing equipment with broad applications. Primarily utilized for separating valuable metal minerals from ores, it excels in processing:

- Sulfide ores: Including chalcopyrite, galena, sphalerite, and molybdenite. These minerals naturally exhibit hydrophobic properties, facilitating efficient separation from the slurry through flotation reagents.

- Oxide ores: Such as copper oxide, lead oxide, and zinc oxide. These minerals require activation to induce hydrophobicity for successful flotation separation.

- Precious metal ores: Including gold and silver. Cyanidation or thiourea processes are commonly employed for the flotation of these precious metals.

- Non-metallic ores: Like graphite, fluorite, and apatite. Specific conditions are required to achieve flotation separation for these non-metallic minerals.

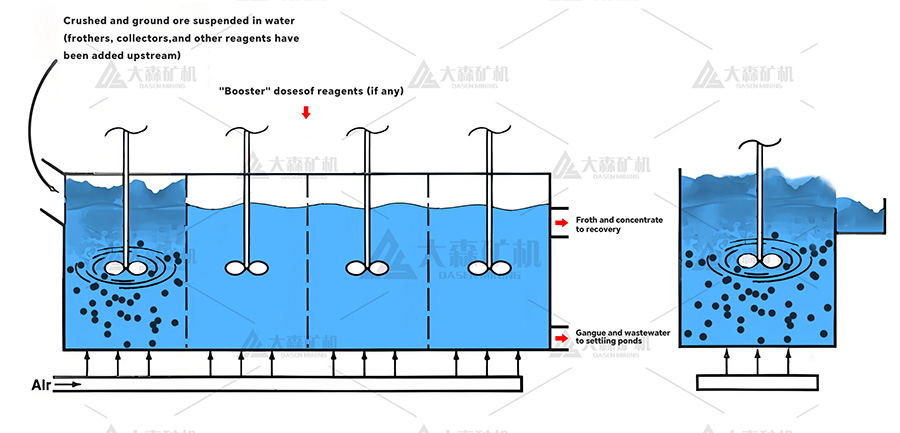

Working Principle:

The SF flotation cells incorporates an automatic control system for precise pulp level adjustment. Its impeller features backward-inclined upper and lower blades, creating upward and downward slurry circulation, respectively. As the impeller rotates, centrifugal force develops within the upper and lower impeller cavities, generating a negative pressure zone. Slurry from the upper part of the tank is drawn into the upper impeller cavity, forming an upper circulation. Simultaneously, the lower blade discharges slurry outwards, while the center is replenished with slurry from below, establishing a lower circulation. Air is drawn into the upper impeller cavity through a suction pipe and central cylinder, mixing with the slurry to produce fine bubbles. These bubbles disperse evenly throughout the tank, attaching to hydrophobic mineral particles and forming a mineralized froth. A scraper removes this froth, yielding the concentrate product.

| Model | Effective

Volume (m³) |

Capacity

(m³/min) |

Diameter of impeller

(mm) |

Impeller

Revolution (r.p.m) |

Motor power

For agitation (kw) |

Motor power

For scraper (kw) |

Weight of

Single tank (kg) |

| SF-0.37 | 0.37 | 0.2-0.4 | 300 | 352-442 | 1.5 | 0.75 | 470 |

| SF-0.7 | 0.7 | 0.3-1.0 | 350 | 400 | 3 | 1.1 | 970 |

| SF-1.2 | 1.2 | 0.6-1.2 | 450 | 312 | 5.5 | 1.1 | 1400 |

| SF-2.8 | 2.8 | 1.5-3.5 | 550 | 268 | 11 | 1.5 | 2242 |

| SF-4 | 4 | 2.0-4 | 650 | 235 | 15 | 1.5 | 2600 |

| SF-8 | 8 | 4.0-8 | 760 | 191 | 30 | 1.5 | 4292 |

| SF-16 | 16 | 5.0-16 | 850 | 169-193 | 45 | 1.5 | 7415 |

| SF-20 | 20 | 5.0-20 | 760 | 186 | 30X2 | 1.5 | 9823 |

Structural Characteristics of the SF Froth Flotation Machine

The SF Froth Flotation Machine incorporates several key design features:

- Dual slurry circulation: Backward-inclined, double-sided blades facilitate efficient slurry circulation within the tank.

- High suction capacity: A substantial clearance between the impeller and cover plate ensures optimal suction performance.

- Reduced wear: The impeller operates at a low circumferential speed, extending the lifespan of wear components.

- Efficient foam movement:

SF Flotation Cells Advantages:

- Energy Efficient: Compared to traditional mechanical stirring flotation machines, our product can reduce energy consumption by 30-50%.

- Enhanced Coal Quality: Our product delivers significantly higher separation accuracy and lower ash content in clean coal. Specifically, it can reduce ash content by 1-2% compared to conventional mechanical stirring flotation machines.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: