Description

Name: mixing tank, chemical mixing tanks, stainless mixing tanks, industrial mixers

Product use: mixing and mixing pulp Product material: conventional manganese steel, can be customized

Motor power: 5.5kw

Feed particle size: 1-100mm

Processing capacity: 3-800T/h

Stirrer diameter: 240-850mm

Effective volume: 0.26-30m³

Structure: right-angle blowing valve, reducer coupling, motor, beam bracket, stirring impeller, main shaft, circulation (barrel) tank, and other structures.

Working Principle:

A mixing drum employs a motor-driven impeller rotating within the drum to thoroughly blend medicine and pulp. This agitation accelerates chemical reactions, enhancing product quality. The mixing tank is versatile, suitable for processing various metal ores, primarily in pre-flotation preparation. The stirrer is designed to handle pulps with a maximum concentration of 30%, density of 3.5, and particle size of 1mm.

Mixing Tanks: A Cornerstone in Mineral Processing

Mixing tanks are indispensable equipment in the mining industry, particularly within concentrators. They serve a crucial role in numerous processes.

Mixing Functions

Mixing tanks fulfill a variety of purposes:

- Homogenization: Blending two or more liquids into a uniform solution.

- Emulsification: Combining immiscible liquids to create a stable emulsion.

- Gas Dispersion: Incorporating gas into a liquid.

- Solid Suspension: Dispersing solid particles within a liquid.

- Process Enhancement: Accelerating chemical reactions, heat, and mass transfer.

Mixing is an essential operation in both metallic and non-metallic mineral processing, hydrometallurgy, and the extraction of rare and precious metals.

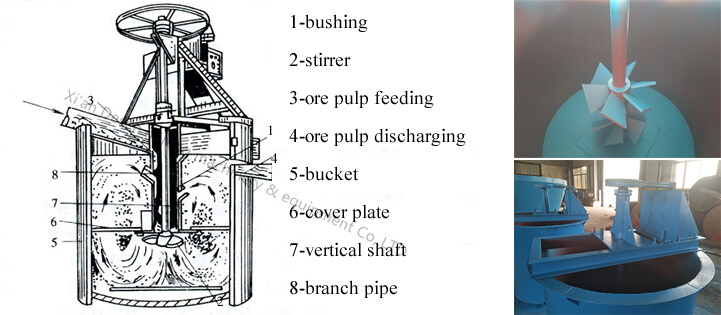

Mixing Tank Components

A typical mixing tank comprises the following:

- Tank: The primary vessel containing the mixture.

- Agitator Shaft: A vertical rotating shaft equipped with mixing impellers.

- Drive System: A motor and transmission mechanism (either belt or gear-driven).

- Auxiliary Components: Supporting structures, inlet and outlet pipes, baffles for flow control, and circulation devices.

By effectively combining these components, mixing tanks provide the necessary conditions for various mixing processes in the mining industry.

Instructions for Use

- Pre-Operation Check: Before operating the mixer, verify the rotational direction of the shaft substitute wheel and securely tighten all bolts on the pump body. Subsequent procedures are identical to those of a flotation machine.

- Wear Parts: The impeller and stator are considered wear parts and should be inspected and replaced as needed.

- Maintenance: Regularly clean the interior of both the mixer and automatic feeder, especially during winter months, to extend their service life.

Product Advantages:

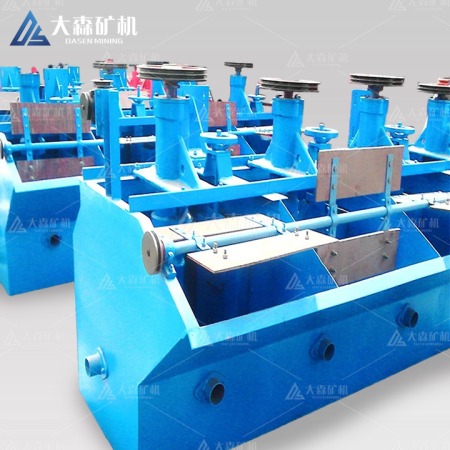

- Superior Mixing Performance: Delivers robust and consistent stirring, preventing solid phase separation or settling, and ensuring optimal mineralization.

- Efficient Design: Compact structure, stable product quality, easy operation, and high utilization rate contribute to efficient production processes.

- Durable Construction: Advanced wear-resistant materials in the stirring wheel and diversion/rectification device extend equipment lifespan.

- Continuous Operation: Direct start-up without unloading after system shutdown preserves pulp moisture and reduces labor demands.

- Energy and Resource Savings: Significantly reduces energy consumption, oil, and additive usage by 20-40% and 20% respectively compared to traditional stirring tanks, while achieving uniform dispersion.

| Model | Internal size of trough | Effective

Volume (M³) |

Stirrer | Motor | Dimension(mm) | Weight

(kg) |

||||

| Dia | Height | Dia(mm) | Speed(r/min) | Model | Power(kw) | Length | Height | |||

| RJ05 | 500 | 500 | 0.078 | 150 | 690 | Y80M2-4 | 0.75 | 720 | 874 | 110 |

| RJ07 | 750 | 750 | 0.26 | 240 | 530 | Y90L-4 | 1.5 | 939 | 1241 | 228 |

| RJ10 | 1000 | 1000 | 0.58 | 240 | 530 | Y90L-4 | 1.5 | 1080 | 1665 | 350 |

| RJ12 | 1200 | 1200 | 1.14 | 400 | 320 | Y132S-6 | 3 | 1540 | 1858 | 765 |

| RJ15 | 1500 | 1500 | 2.2 | 400 | 320 | Y132S-6 | 3 | 1690 | 2771 | 1360 |

| RJ20 | 2000 | 2000 | 5.5 | 550 | 230 | Y132M2-6 | 5.5 | 2381 | 3046 | 1655 |

| RJ25 | 2500 | 2500 | 11 | 625 | 230 | Y160M-6 | 7.5 | 2881 | 3546 | 2766 |

| RJ30 | 3000 | 3000 | 19.1 | 900 | 210 | Y225S-8 | 18.5 | 3266 | 4325 | 4296 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]