Description

Name: Roller Crusher, Double Roller Crusher, Toothed Roll Crusher, Double toothed roll crusher

Motor power: 75kw

Feed particle size: ≤40mm

Production capacity: 5-110t/h

Uses: Crushing medium and high-hardness materials in metallurgy, construction, refractory materials and other industries.

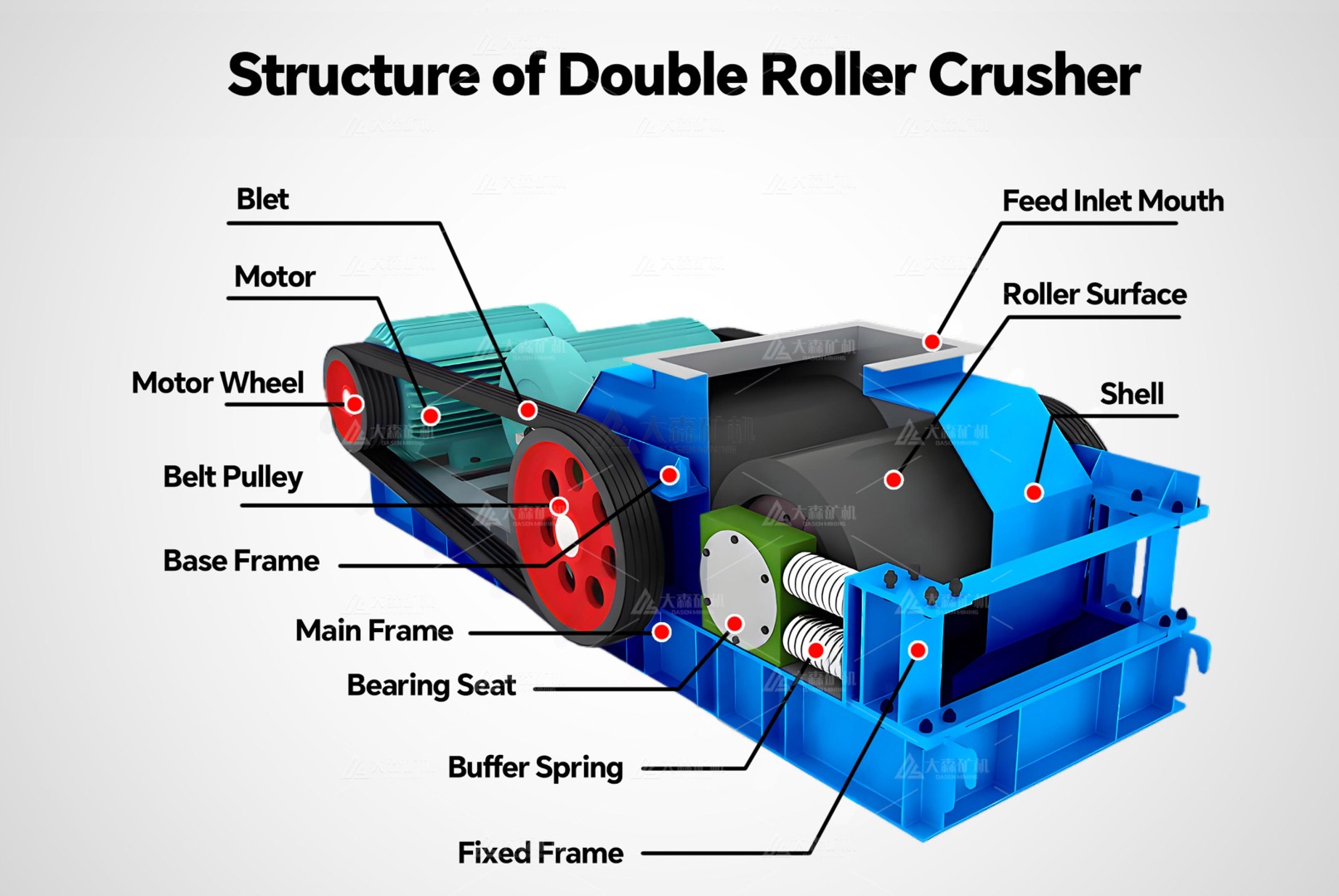

Structure: Roller assembly, roller support bearing, pressing and adjusting device, drive device, etc.

Double-toothed roll crushers, also known as toothed roller crushers, are widely employed for the coarse and intermediate crushing of brittle materials across various industries including mining, metallurgy, construction, refractories, chemicals, coal, and building materials. In the coal industry specifically, raw coal can be directly fed into the crusher after removing iron and impurities, eliminating the need for additional gangue removal processes. This streamlined approach contributes to lower investment and operational costs.

Structural Features:

When integrated into a sand making production line, the hydraulic double-roller mill maximizes production capacity. Equipped with a dust-proof plate, the mill effectively seals the interior, preventing material splash and dust dispersion. This design significantly reduces noise and improves overall working conditions.

Working Principle

A toothed roll crusher operates using two electric motors, each driving a roller via V-belts and pulleys. The rollers rotate in opposite directions. Material is fed into the crusher and is crushed by the interlocking teeth of the rollers. The crushed product is discharged from the bottom of the machine.

Features

- High efficiency and energy savings: The compact design boosts output by 30-40% while reducing energy consumption by 20-30%.

- Adjustable output: The discharge particle size can be easily adjusted using a handwheel or hydraulic system.

- Durable construction: The crusher features thick, wear-resistant roller skins for extended lifespan.

- Precise particle size control: The low over-crushing rate and adjustable gap between rollers ensure precise particle size distribution to meet various material requirements.

- Safe operation: The machine is equipped with an automatic lubrication system and high-strength steel construction.

- Powerful motors: The crusher is driven by two powerful, reliable motors with a warranty.

- Anti-blockage system: An integrated balance flashback protection system with automatic retreat technology prevents damage from foreign objects.

| Model | Technical properties | Motor(kW) | Dimension(mm) | Weight(kg) | ||

| Feeding size(mm) | Output size(mm) | Capacity(t/h) | ||||

| 2PGC400x250 | <16 | 2-5 | 2.3-2.5 | 2×5.5 | 2245x940x718 | 3600 |

| 2PGC310x400 | <36 | 2-9 | 3-9 | 2×11 | 1785x2365x1415 | 3800 |

| 2PGC750x500 | <40 | 2-10 | 7-12 | 2×15 | 2720x2700x1400 | 10250 |

| 2PGC750x700 | <40 | 5-10 | 15-25 | 2×22 | 3422x2800x1705 | 11700 |

| 2PGC750x1000 | <40 | 2-10 | 6-30 | 2×30 | 4150x2800x1750 | 12500 |

| 2PGC900x500 | <40 | 2-10 | 9-30 | 2×22 | 2750x1790x2065 | 14000 |

| 2PGC900x900 | <40 | 2-10 | 11-45 | 2×30 | 2750x2180x2065 | 16800 |

| 2PGC900x1200 | <40 | 3-10 | 15-60 | 2×55 | 2750x2480x2065 | 20800 |

| 2PGC900x800 | 25-90 | 3-40 | 12-50 | 2×45 | 2940x2080x2065 | 22600 |

| 2PGC1200x1000 | <40 | 3-12 | 10-50 | 2×37 | 3690x3430x2700 | 46820 |

| 2PGC1200x1200 | <40 | 3-12 | 18-68 | 2×75 | 3690x3630x2700 | 14600 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]