Description

Name: Ball Mill, vibrating ball mill, ball mill mining, ball mill crusher, Ball mill grinder

Loading capacity: 1.5-338T

Feed particle size: ≤25mm

Production capacity: 0.17~170t/h

Uses: Widely used in the cement industry, new construction industry, ferrous and non-ferrous metal beneficiation, glass ceramics and other production industries.

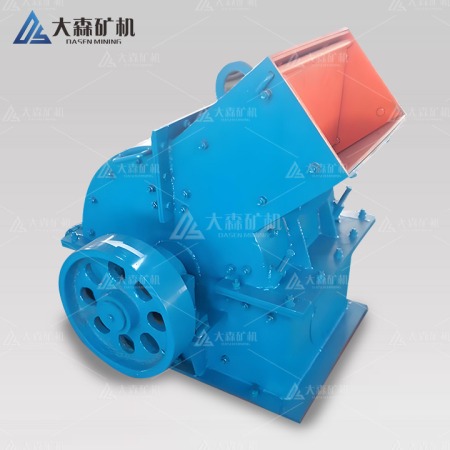

Structure: The ball mill consists of the feeding part, the discharging part, the rotating part, the transmission part (reducer, small transmission gear, motor, electric control) and other main parts.

Ball mills are essential equipment for efficient crushing and grinding. Widely used across industries such as cement, silicate products, building materials, refractories, fertilizers, and mineral processing, these machines handle a vast array of materials including ores, minerals, and other grindable substances.

Ball mills operate through dry or wet processes, and their discharge mechanisms can be classified as either lattice or overflow types. This versatility makes them indispensable tools for achieving desired particle sizes in various applications.

Key Features

- Reliable and Efficient: The ball mill operates smoothly with minimal downtime, enhancing overall productivity.

- Durable Construction: Featuring a cast steel hollow shaft, replaceable inner lining, and cast-honed large rotary gear, the mill is built for longevity. Wear-resistant lining plates further protect the equipment.

- Versatility: Choose between dry or wet grid ball mills to accommodate various materials and processing requirements.

- Energy Efficient: By utilizing rolling bearings instead of traditional sliding bearings, energy consumption is reduced by 10-20%, resulting in lower operating costs.

- Flexible Feeding: Drum or combined feeders can be selected to match specific process conditions.

- Cost-Effective Performance: This ball mill offers exceptional grinding capabilities at a competitive price point.

Design and Operation

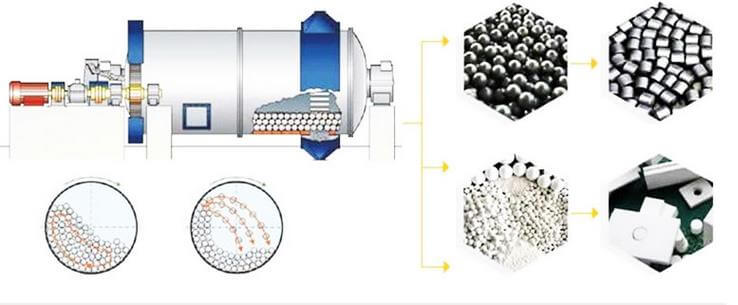

The ball mill grinder is a horizontally oriented cylinder equipped with end caps housing hollow journals supported by bearings. The cylinder is filled with grinding media, typically steel or ceramic balls. Optimal performance is achieved by maintaining a balanced distribution of ball sizes, with the total ball load constituting 40-50% of the cylinder’s effective volume.

Working Principle

The ball mill grinder operates by introducing material into the hollow shaft at its feed end. As the cylindrical barrel rotates, the grinding media (steel balls) are carried upward due to inertia, centrifugal force, and friction. Upon reaching a certain height, these balls cascade downward, impacting the material and causing it to break down through force and attrition.

Material enters the first chamber of the ball mill in a uniform, spiral pattern through the hollow feed shaft. This chamber features stepped or corrugated liners and contains a mix of steel ball sizes. Centrifugal force generated by the rotating cylinder lifts the steel balls, which subsequently fall and grind the material. Once the material undergoes initial grinding in the first chamber, it passes through a single-layer partition into the second chamber. Equipped with flat liners and steel balls, the second chamber continues the grinding process until the desired particle size is achieved. Finally, the finished product is discharged through the outlet grate.

Advantages

- Enhanced Lining Plate Durability: The lining plate, subjected to an advanced double-medium quenching process, exhibits exceptional wear and impact resistance. It maintains its shape under heavy production loads, minimizing deformation and wear.

- Versatile Lining Plate Performance: Compared to traditional high manganese steel liners, our medium alloy, double-medium quenched lining plates offer superior cost-effectiveness. They excel in both wet and dry grinding conditions, handling various ores and rocks efficiently.

- Increased Gear Strength: The use of displacement gears significantly enhances gear bending strength, eliminating undercutting issues common in traditional designs.

- Improved Bearing Lifespan: By enlarging the hollow shaft diameter, we’ve increased the radial clearance between the bearing and the feed/discharge screw cylinder. This improved heat dissipation prolongs bearing life.

- Energy Efficiency and Reduced Wear: Our thin oil lubrication system replaces traditional grease lubrication, reducing friction and wear on bearings and other components. This results in lower energy consumption and extended equipment life.

| Model | Drum size(mm) | Rotary speed(r/min) | Ball loading(t) | Feeding size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

| GM0715 | 750*1500 | 44.09 | 0.9 | 0-25 | 0.2-0.6 | 7.5 | 2.3 |

| GM0909 | 900*900 | 41.6 | 0.83 | 0-25 | 0.2-0.7 | 11 | 3.8 |

| GM0912 | 900*1200 | 41.6 | 1.1 | 0-25 | 0.3-0.9 | 11 | 4.2 |

| GM1224 | 1200*2400 | 35.2 | 4 | 0-25 | 1.6-4.1 | 30 | 10 |

| GM1324 | 1300*2400 | 30.2 | 4.5 | 0-25 | 1.5-3.5 | 37 | 10.2 |

| GM1830 | 1800*3000 | 27 | 13 | 0-25 | 3-17 | 130 | 23.5 |

| GM2121 | 2100*2100 | 23.8 | 11.5 | 0-25 | 3-22 | 130 | 38.7 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]