Description

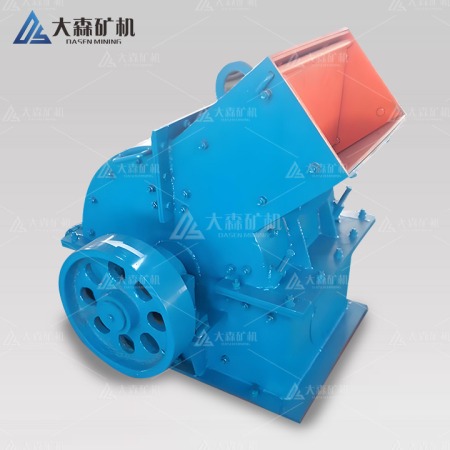

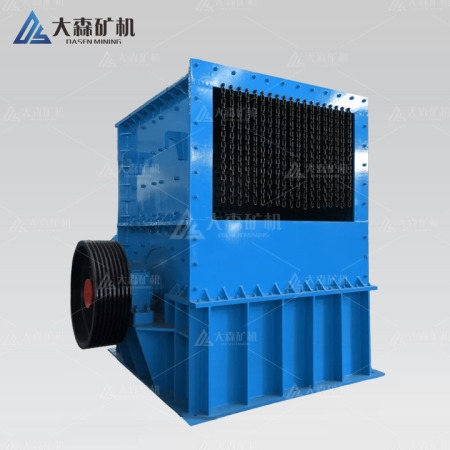

Product Name: Impact Crusher, Impact crusher machine, Impact crusher manufacturer,Impact hammer mill

Capacity: 15-550(t/h)

Model: PF-0807–PF-1520

Features: Large crushing ratio, uniform product size and less over-crushing phenomenon, low energy consumption, large adjustment range of product size, and selective crushing.

Scope of application: Processing medium-hard materials with a side length of 100-500mm and a compressive strength of no more than 350MPa.

Applicable materials: river pebble, granite, basalt, iron ore, limestone, quartz stone, coal gangue, construction waste, etc.

Structure: composed of plate hammer, pressing block, counterattack plate, and square steel.

Impact hammer crushers are designed for efficiently crushing coarse, medium, and fine materials such as granite, limestone, and concrete. Suitable for materials with a maximum side length of 500mm and compressive strength up to 350 MPa, these crushers find extensive application in the mining, highway, railway, and construction industries.

As a PF impact crusher functions, it leverages the principle of impact crushing. High-speed hammers strike and shatter materials, resulting in a finer product compared to jaw-crushing methods. This type of crusher is often used in conjunction with jaw crushers for optimal particle size reduction.

Five Advantages of Impact Crushers in the Crushing Process

1. Efficient Handling of Wet Materials

Impact crushers excel at processing wet materials without clogging. This is achieved by eliminating the need for a bottom sieve plate and optionally incorporating a heating device on the feed chute and impact plate to prevent material adhesion.

2. Superior Performance on Hard Materials

Due to their robust design, impact crushers are particularly well-suited for crushing hard materials. The firmly mounted plate hammers and high-momentum rotor enable efficient reduction of tough feedstock while consuming less energy compared to hammer crushers.

3. Flexible Particle Size Adjustment

Impact crushers offer precise and adaptable particle size control. By modifying rotor speed and the gap between the impact plate and grinding chamber—either mechanically or hydraulically—operators can easily achieve the desired product specifications.

4. Minimal Wear and High Metal Utilization

Impact crusher components exhibit exceptional durability and efficiency. The plate hammers primarily wear on the impact face, while the remainder of the hammer and other parts remain largely unaffected. This minimizes replacement frequency and maximizes material utilization.

5. Easy Maintenance and Reduced Costs

Regular maintenance is simplified by the impact crusher’s design. With only six plate hammers, replacements can be performed quickly and efficiently using specialized tools, contributing to overall cost savings.

Working Principle:

PF impact crusher operate by utilizing impact energy to reduce material size. During operation, a motor propels the rotor to high speeds. As material enters the crusher, it encounters the high-speed plate hammers, which strike and break it down. The crushed material is then redirected toward impact liners for further reduction before being propelled back into the path of the plate hammers for additional crushing. This process repeats as material progresses through multiple impact chambers until the desired particle size is achieved. The final product is discharged through the outlet port.

Advantages:

- High Capacity and Material Adaptability: The machine features a large feed opening and deep crushing chamber, making it ideal for processing hard, large blocks with minimal stone powder content.

- Precise Particle Control: Easy adjustment of the gap between the impact plate and hammer allows for precise control over particle size and shape.

- Robust and Compact Design: Built with a compact, rigid structure and high moment of inertia, the machine offers exceptional stability and durability.

- Durable Impact Components: Chrome-plated hammers deliver high impact force, resistance, and wear life.

- Efficient and User-Friendly Operation: The keyless connection mechanism ensures easy maintenance and reduced downtime while delivering reliable performance.

- High-Performance Crushing: The machine excels in comprehensive crushing, offering high productivity, low wear, and optimal efficiency.

| Model | Specification (mm) | Feeding size(mm) | Max feeding edge(mm) | Capacity(t/h) | Power(kw) | Weight(t) | Overall dimension(l*w*h)(mm) |

| PF-1007 | Φ1000*700 | 400*730 | 300 | 25-45 | 30-55 | 9.5 | 2400*1558*2660 |

| PF-1010 | Φ1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 12.2 | 2400*2250*2620 |

| PF-1210 | Φ1250*1050 | 400*1080 | 350 | 80-120 | 110-132 | 14.1 | 2690*2338*2890 |

| PF-1214 | Φ1250*1400 | 400*1430 | 350 | 110-132 | 132-160 | 18.6 | 2690*2688*2890 |

| PF-1310 | Φ1300*1050 | 490*1170 | 400 | 132-160 | 110-160 | 16.2 | 2780*2478*2855 |

| PF-1315 | Φ1320*1500 | 860*1520 | 500 | 180-260 | 180-260 | 19.3 | 3096*3273*2667 |

| PF-1415 | Φ1450*1500 | 900*1650 | 500 | 260-280 | 260-280 | 24 | 3400*3500*3280 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]