Description

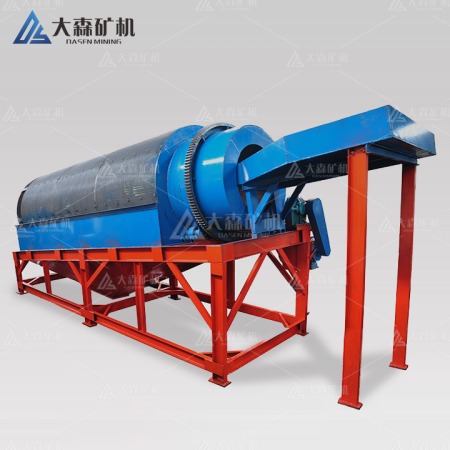

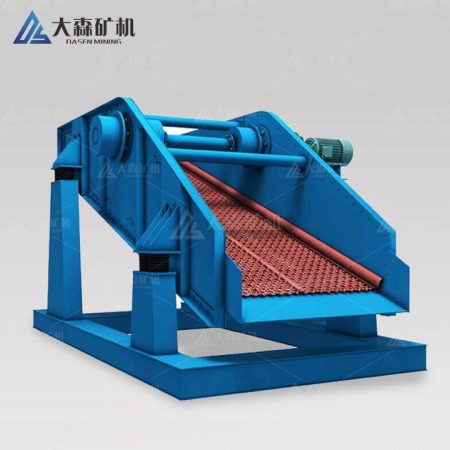

Name: circular vibrating screen, vibrating screen

Length of screen surface: 6000mm

Material trajectory: approximate circular motion

Processing capacity: 20-500t / h

Application site: The system is widely used in mining, chemical processing, cement, building materials, and other departments, for uniform and continuous feeding from silos to crushers, and for transporting equipment.

Vibrating Screen Overview

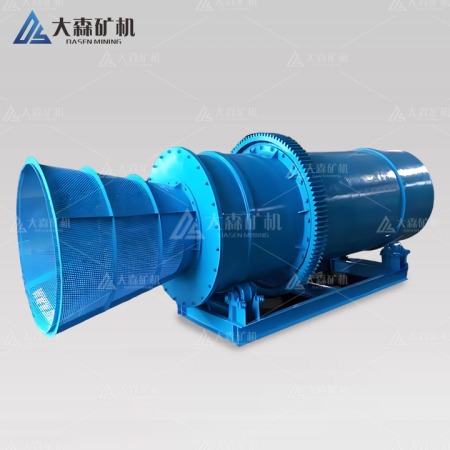

A vibrating screen typically consists of a spring base, rotating mandrel, pulley, screen mesh, eccentric block, bearing, excitation wall, screen box, and motor. Circular vibrating screens, characterized by their circular motion, multiple layers, and high efficiency, represent a newer generation of vibrating screening equipment. These screens are known for their robust construction, powerful vibration, high screening capacity, low noise and vibration levels, and easy maintenance. They find widespread application in mining, construction, transportation, energy, chemical, and other industries for material classification.

Advantages of Vibrating Screens

Equipped with wear-resistant components, vibrating screens are designed for durability and easy maintenance. Unlike welded constructions, the screen and screen box are securely fastened with bolts, preventing vibration-induced cracks and facilitating replacement. As a versatile piece of equipment, vibrating screens are employed in coal, mineral processing, and other industries for material classification, washing, dewatering, and separation.

The linear vibrating screen, also referred to as a dual-axis inertial vibrating screen, is another type of vibrating screen renowned for its high productivity, effective classification, easy maintenance, compact size, lightweight design, high efficiency, and multi-layer capability. The dynamic performance of vibrating screens significantly impacts their screening efficiency and overall lifespan.

Working Principle:

A vibrating screen utilizes a vibrating motor to generate oscillatory motion, propelling material upwards across the screen surface in a linear direction. Undersized particles pass through one outlet, while oversize particles are discharged from the other. Renowned for its stability, reliability, low energy consumption, noise reduction, durability, consistent vibration pattern, and high screening efficiency, the linear vibrating screen is a high-capacity, cutting-edge screening equipment widely employed in mining, coal, metallurgy, construction, refractory, light industry, and chemical industries.

Vibrating Screen Performance Characteristics

- Adjustable Inclination: The vibrating screen’s angle can be modified using the spring base to optimize material throughput.

- Torsion Protection: A tire coupling is integrated to safeguard the motor from start-up torsion damage.

- Powerful Vibration: An eccentric vibration exciter generates strong vibrations for efficient material screening.

- Reduced Component Stress: The vibrating screen body is engineered to minimize vibrations, extending component lifespan.

- Durable Screen Frame: High-strength bolts secure the screen frame, enhancing its resistance to high-amplitude vibrations and preventing breakage.

- Wear Resistance: Wear-resistant blocks protect the excitation wall for prolonged durability.

- Multi-Layer Screening: A three-layer screen configuration ensures precise and efficient material classification.

- Easy Maintenance: The screen assembly is secured by bolts, simplifying replacement and maintenance.

| Model | Layer | Screen area(m2) | Screen size(mm) | Max screen size(mm) | Capacity(t/h) | Vibrating frequency(r/min) | Power(kw) | Dimension(mm) |

| 3YS1236 | 3 | 12.96 | 3-50 | 150 | 20-80 | 800-970 | 7.5 | 1200*3600 |

| 4YS1236 | 4 | 14.4 | 3-50 | 150 | 20-85 | 800-970 | 7.5 | 1200*3600 |

| 2YS1548 | 2 | 14.4 | 5-50 | 200 | 40-196 | 960 | 15 | 1500*4800 |

| 3YS1548 | 3 | 21.6 | 5-50 | 200 | 40-216 | 960 | 15 | 1500*4800 |

| 4YS1548 | 4 | 28.8 | 5-50 | 200 | 40-220 | 960 | 15 | 1500*4800 |

| 2YS1854 | 2 | 19.44 | 5-100 | 300 | 63-486 | 960 | 22 | 1800*5400 |

| 3KY1854 | 3 | 29.16 | 5-100 | 300 | 63-500 | 960 | 22 | 1800*5400 |

Vibrating Screen Applications

Vibrating screens are indispensable in the mineral processing industry for tasks such as sizing, classification, and dewatering. They are commonly used in conjunction with crushing equipment to produce materials of specific particle sizes. Key applications include:

- Mining: Processing ores, coal, and minerals.

- Construction: Screening aggregates for concrete, asphalt, and other construction materials.

- Industrial: Processing materials in industries like chemicals, pharmaceuticals, and food.

Vibrating screens offer numerous advantages, including high efficiency, low maintenance, and the ability to handle a wide range of materials and capacities.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]