Description

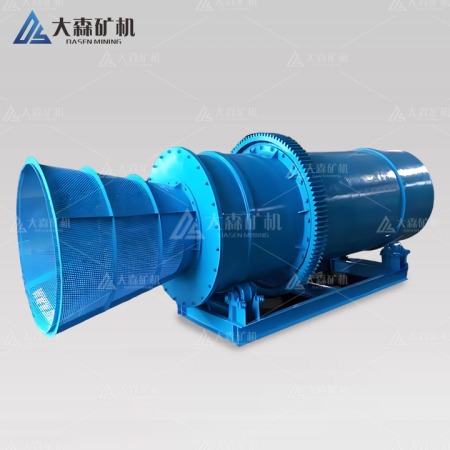

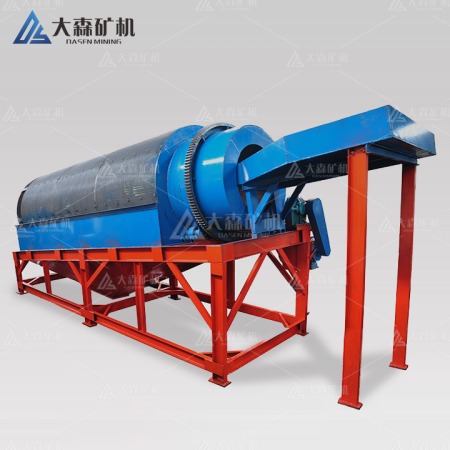

Name: 2.3*12m large cylinder washing machine, new type rotary scrubber, drum washing machine, drum washer

Feeding particle size: <200mm

Motor power: 30kw*4 sets

Production capacity: 200-300t/h

Equipment weight: 31t

Application: Used in the cleaning process of minerals such as manganese, iron, limestone, tungsten, tin, and silica sand.

A washing rotary drum scrubber employs rotating cylinders and internal scrapers, in conjunction with naturally occurring pebbles and rocks within the material, to effectively break down clay, lumps, and soft oxides. Operating on a principle similar to a large washing machine, the drum rotates slowly while mixing materials of varying sizes with water. This intensive agitation releases valuable minerals from the surrounding mud and clay. The resulting slurry is then propelled towards the machine’s outlet by the cylinder and subsequently fed into a conical screen. This screening process removes oversized particles, allowing the undersized slurry to proceed directly to downstream mineral processing equipment.

A washing rotary drum scrubber delivers exceptional performance in various applications. Key benefits include:

- Uniform Particle Size: The elongated drum design ensures extended material retention, resulting in thorough dispersion and consistent product quality.

- Superior Washing and High Capacity: Equipped with heavy-duty components and high-torque motors, the scrubber offers powerful cleaning action and can handle large volumes of material.

- Enhanced Reliability: Precise component clearances minimize vibration, reducing the risk of equipment failure and extending the scrubber’s lifespan.

- Versatile Feed Handling: The scrubber can process materials with a feed size of up to 200mm, accommodating a wide range of applications.

- Cost-Effective Operation: Low energy consumption and reduced investment requirements make the scrubber an economical choice compared to similar technologies.

Rotary scrubbers are industrial machines designed to effectively clean large, challenging-to-process ores. There are two primary types: cylinder scrubbers and cylinder-screen scrubbers. These machines can classify washed material into two sizes: +40mm and -40mm. To further refine the -40mm fraction, a double spiral trough washing machine can be employed to create additional classifications of +2mm and -2mm, significantly enhancing overall washing efficiency. This combined system boasts an impressive 98% cleaning efficiency, making it particularly suitable for refractory ores.

Working Principle

A washing rotary drum scrubber operates on a rotational principle. Supported by four trunnions, the cylindrical drum is driven by a motor and gear reducer to rotate at a low speed. The ore, containing mud and sand, is continuously fed into the rotating drum where it undergoes intensive agitation by internal lifting paddles. This action effectively disperses the material.

High-pressure water jets are directed into the drum, either forward or reverse, to thoroughly wash the ore as it moves towards the discharge end. The resulting wastewater, carrying suspended solids, is collected at the discharge point and transferred to a sedimentation tank for clarification. The treated water can then be recycled for further washing.

| Model | Drum

Size(m) |

Screen

Mesh(mm) |

Feeding

Size(mm) |

Capacity

(t/h) |

Speed

(r/min) |

Power

(kw) |

Water required(m3/h) | Weight(t) |

| RC1030 | 1*3 | ≥5 | ≤100 | 6-10 | 25-28 | 15 | 1.5-4 | 4.8 |

| RC1230 | 1.2*3 | ≥5 | ≤100 | 10-15 | 23-25 | 18.5 | 1.5-4 | 5.8 |

| RC1545 | 1.5*4.5 | ≥5 | ≤150 | 15-25 | 18-22 | 30 | 1.5-4 | 6.9 |

| RC1560 | 1.5*6 | ≥5 | ≤150 | 20-50 | 18-22 | 37 | 1.5-4 | 8.3 |

| RC1845 | 1.8*4.5 | ≥5 | ≤170 | 50-80 | 20-21 | 45 | 1.5-4 | 11.8 |

| RC1860 | 1.8*6 | ≥5 | ≤170 | 80-100 | 20-21 | 45 | 1.5-4 | 12.8 |

| RC2060 | 2.0*6 | ≥5 | ≤210 | 100-120 | 19-20 | 55 | 1.5-4 | 14.8 |

| RC2265 | 2.2*6.5 | ≥5 | ≤230 | 120-140 | 19-20 | 55 | 1.5-4 | 16.5 |

Drum washing machines are renowned for their robust construction, extended lifespan, and user-friendly operation. Our drum washing machines feature an enclosed design that effectively protects critical components, such as the impeller, from water exposure. This innovative approach eliminates the risk of bearing wear caused by water immersion.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]