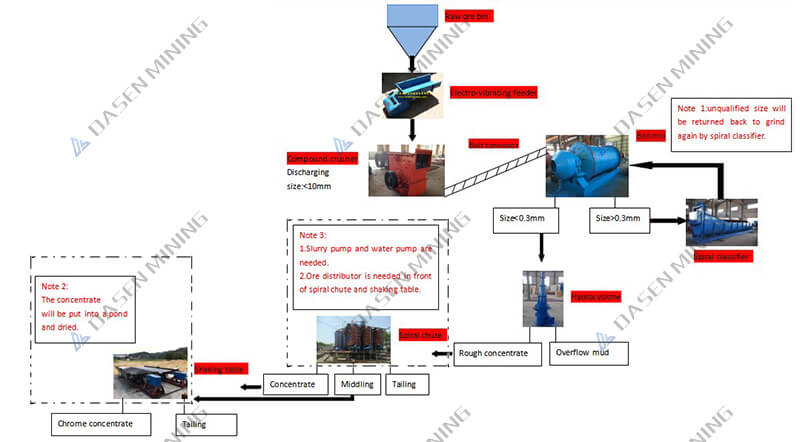

The chromium ore production process is not only the chromium ore production and processing process but also the chromium ore production process is becoming more and more simple because of the multi-function of the equipment and the high degree of integration of today’s equipment. It consists of the following three parts:

1. Chrome ore is first fed into a jaw crusher for preliminary crushing, and secondary crushing is required if it does not meet the requirements.

2. Secondly, the small chromium ore from the crushing equipment is sent to the ball mill or rod mill at a uniform speed through the auxiliary equipment for effective grinding, and then the chromium ore is screened and graded by the classifier. This step is to effectively filter out the impurities, to reduce the impurity content of chromium ore.

3. Gravity beneficiation is carried out with a spiral chute or shaking table. According to the characteristics of gravity beneficiation, the impurities in chromium ore are filtered out, and then the chromium mineral after beneficiation can be obtained through the operation process of thickener and dryer, so the whole beneficiation miner is over.