Description

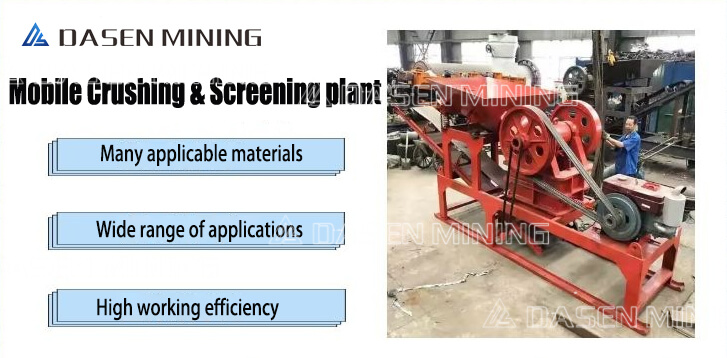

The mobile crusher plant station is a highly efficient and versatile solution for primary crushing applications. It integrates a jaw crusher, vibrating feeder, and vibrating screen into a single unit, ensuring optimal performance and productivity. The vibrating feeder plays a crucial role in reducing the load capacity of the jaw crusher, thereby enhancing overall production efficiency. Widely utilized in various applications, the mobile jaw crusher is particularly effective for primary crushing in mountain extraction operations. With a capacity range of 50-500t/h, it offers robust and reliable performance to meet diverse crushing needs

Mobile crushing plants distinguish themselves from other machinery by incorporating three stages of crushing.

Although these plants have been in existence for quite some time, they are currently experiencing a surge in popularity. This surge can be attributed to their unique features, including minimal space requirements, enhanced production capacity, environmental sustainability, and exceptional mobility. Presently, mobile crushing plants represent the pinnacle of advanced crushing technology. They are predominantly utilized in mining operations and construction sites for both screening and crushing tasks.

There are two specifications for this mobile crushing station: A and B

Specification A:

Capacity: 20-30tph

Feeding machine: 0830 1.5kw

Jaw crusher: PE300*500 22kw

Hammer crusher: PC 600*800 55kw

Belt conveyor: 800*6000 feeding belt 4kw

Belt conveyor: 800*3000 outputting belt 4kw

Cabinet control box

Mobile steel frame

Fixed outrigger

Total power: 86.5kw

Specification B:

Capacity: 10-20tph

Feeding machine: 0730 1.1kw

Jaw crusher: PE220*350 11kw

Hammer crusher: PC 400*600 30kw

Belt conveyor: 650*6000 feeding belt 3kw

Belt conveyor: 650*3000 outputting belt 3kw

Cabinet control box, Mobile steel frame, Fixed outrigger

Total power:48.1kw

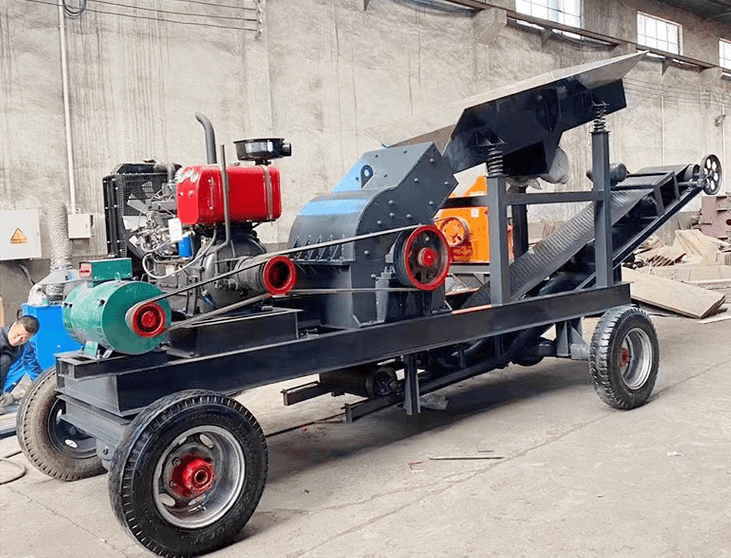

The mobile crushing plant offers a high degree of operational flexibility, allowing the operator to fully adjust its three stages. For instance, the operator can opt to crush first, then screen, and crush again to achieve an optimal final product. Additionally, being mounted on a truck frame or a similar mobile platform, the plant can transport the finished product directly to the desired location upon completion of the crushing process. This mobility is just one of the many advantages, with the following three major benefits standing out:

- Low Operating Costs: The mobile crushing plant is designed to minimize operational expenses, making it a cost-effective solution for various crushing needs.

- Reliable & Efficient Performance: Engineered for consistent and efficient operation, the plant ensures high productivity and reliability.

- Versatile & Flexible Configuration: The plant’s adaptable design allows it to be configured to meet diverse crushing requirements, enhancing its utility across different applications.

In every aspect, the mobile crushing plant delivers a finished product with uniform particle sizes, meeting a wide range of needs.

The mobile crusher station is capable of crushing over 200 different types of materials, making it highly versatile for a wide range of applications.

Mobile Crusher Plant Station Advantages:

Host Flexible Configuration Host Flexible Configuration

There are dozens of primary crushing plants available to suit the individual needs of customers. They can switch easily between host devices. |

Add Adjustment Function Increasing the installation angle of the vibrating screen on the mobile crushing and screening plant will increase the machine’s capacity. |

Easy to Install Mobile Complete Crushing Plant is a flexible and maneuverable parking function that quickly enters working mode. |

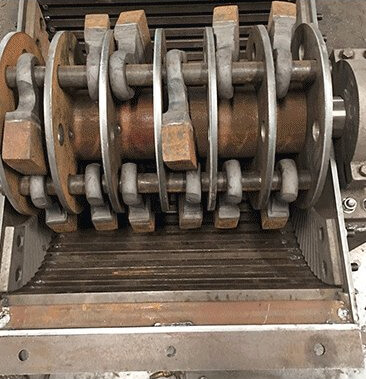

Wear-resistant Hammer The hammerhead is cast by new technology and new technology, which is more wear-resistant and impact-resistant |

Each type of mobile crusher has its components, functions, and unique features

1. Mobile Jaw Crusher

It is mainly equipped with a feeding + jaw crusher + conveyor belt, suitable for coarse crushing, adopts extrusion crushing work, deep cavity and no dead zone, not easy to cause material blockage, coupled with flywheel design, effectively reduces vibration, runs more smoothly, and improves To improve the overall output, gasket type discharge port adjustment device.

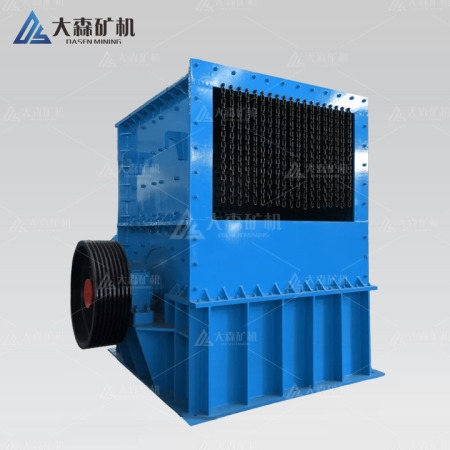

2. Mobile Impact Crusher

It is mainly equipped with an impact crusher + vibrating screen + conveyor belt and uses impact to crush materials. The rotor and crushing cavity are designed for different applications. The machine has strong rigidity, the rotor has a large rotational inertia, and the finished product has an excellent particle shape, which is cubic. Comprehensive High benefit.

3. Mobile Cone Crusher

It is mainly equipped with a feeding + cone + conveyor belt, suitable for medium or fine crushing. It adopts the push-type structure on the low-hanging shaft of the jaw plate, which has the characteristics of high production capacity, long service life of the tooth plate, low energy consumption, and uniform product particle size.

4. Mobile Hammer Crusher

Mainly equipped with feeding + heavy hammer + conveyor belt, suitable for medium crushing, large moment of inertia, large feeding particle size, one-time crushing effect, strong production capacity, high output value, and good particle shape.

We can provide you with more information about the gravity machine and gold processing plant. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]