Description

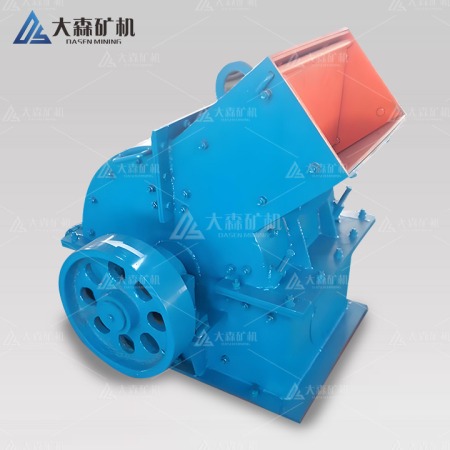

Name: spring cone crusher, cone crusher machine, cone crusher plant

Motor power: 55-280kw

Feed particle size: ≤ 100mm

Production capacity: 50-350t/h

Uses: sand and gravel yard, mining, coal mining, concrete mixing plant, dry powder mortar, power plant desulfurization, quartz sand, etc

Processing materials: Suitable for crushing ores and rocks with medium or above hardness (below 350 MPa).

Structure: The cone crusher is composed of a frame, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, hydraulic system, control system, etc.

High-efficiency cone crushers are spring cone crushers engineered for maximum output and minimal fine particles. Featuring a high swing frequency, optimized cavity design, and precise stroke, these machines deliver exceptional performance. Renowned for their reliability, durability, and cost-effectiveness, they have earned global trust. In fact, high-efficiency cone crushers have consistently outperformed traditional cone crushers in various applications.

Working Principle

A compound and Cone crusher machine primarily consists of a frame, fixed cone assembly, moving cone assembly, spring mechanism, bowl-shaped shaft frame, and transmission system. Auxiliary components include an electrical system, oil lubrication system, and automatic cavity cleaning system.

The crusher operates as follows: A motor powers the eccentric shaft sleeve through a series of gears and pulleys, causing the crushing cone to oscillate within the machine. This oscillatory motion creates a crushing cavity between the fixed and moving cones. As materials enter the cavity, they undergo repeated impact, compression, and shearing forces. This process gradually reduces particle size until the desired product is achieved, which is then discharged from the lower part of the crusher.

Cone Crusher Structural Features

This cone crusher boasts a compact design and high production capacity. It employs a precision bowl-shaped bearing lubricated by a centralized thin oil system. Hydraulic cylinder activation allows for adjustable discharge port size. A spring device safeguards the equipment against damage caused by foreign material entering the crushing chamber.

To prevent oil-water mixing from operational errors, a grease seal is utilized. This seal incorporates a spring mechanism for automatic compensation as it wears, maintaining sealing integrity until replacement is necessary at approximately 1/4 to 1/3 of its original thickness.

A spring insurance system protects the crusher from unbreakable foreign objects or overloading. Upon activation, the ore discharge port widens to expel the obstruction. The spring mechanism subsequently resets the discharge port, allowing normal operation to resume.

Cone crushers offer several key benefits:

- High capacity and product quality: Delivers exceptional production rates while producing superior-quality crushed material.

- Reduced downtime: Equipped with safety features to minimize equipment stoppage and optimize uptime.

- Robust construction: Cast steel body reinforced with heavy-duty ribs for exceptional durability and longevity.

- Precise size adjustment: Integrated regulator allows for quick and accurate adjustment of crushing and discharge particle size.

- Advanced protection: Spring protection device safeguards the equipment from potential damage.

- Intelligent monitoring: Complete lubrication system with automatic shutdown function for overheating or low flow rate prevention.

- Dust and particle prevention: Effective sealing of internal components protects the crusher from contamination.

- Versatility and longevity: Designed for long-term reliable operation across a wide range of applications.

| Model | Crushing cone diameter

(mm) |

Feeding part

size(mm) |

Max feeding size(mm) | The range of discharging part(mm) | Motor power(kw) | Capacity

(t/h) |

Weight(not including the motor)(kg) |

| PYB-900 | 900 | 135 | 110 | 15-50 | 55 | 50-90 | 9600 |

| PYB-1200 | 1200 | 170 | 145 | 20-50 | 110 | 110-168 | 24700 |

| PYB-1750 | 1750 | 250 | 215 | 25-30 | 155 | 280-480 | 50300 |

| PYB-2100 | 2100 | 350 | 300 | 30-60 | 280 | 500-800 | 71200 |

| PYB-2200 | 2200 | 350 | 300 | 30-60 | 280 | 500-1000 | 80000 |

| PYZ-900 | 900 | 70 | 60 | 8-20 | 55 | 20-65 | 9600 |

| PYZ-1200 | 1200 | 115 | 100 | 8-25 | 110 | 42-135 | 25000 |

| PYZ-1750 | 1750 | 215 | 180 | 10-30 | 155 | 115-320 | 50300 |

| PYZ-2200 | 2200 | 275 | 230 | 10-30 | 280 | 200-580 | 84000 |

| PYD-900 | 900 | 50 | 40 | 3-13 | 55 | 15-50 | 9700 |

| PYD-1200 | 1200 | 60 | 50 | 3-15 | 110 | 18-105 | 25300 |

| PYD-1750 | 1750 | 100 | 85 | 5-15 | 155 | 75-230 | 50500 |

| PYD-2200 | 2200 | 130 | 100 | 5-15 | 280 | 125-350 | 85000 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]