Description

Name: Three disk belt electromagnetic separator, electromagnetic conveyor belt, belt electromagnetic separator

Feeding force: < 2ml

Processing capacity: 80-800kg/h

Strong magnetic intensity: 1700-2000 Haote

Motor power: 1.5kw

Three-disc electromagnetic separator is a specialized equipment employed for the separation of magnetic and non-magnetic minerals within tungsten, tin, tantalum, zircon, and rutile ores.

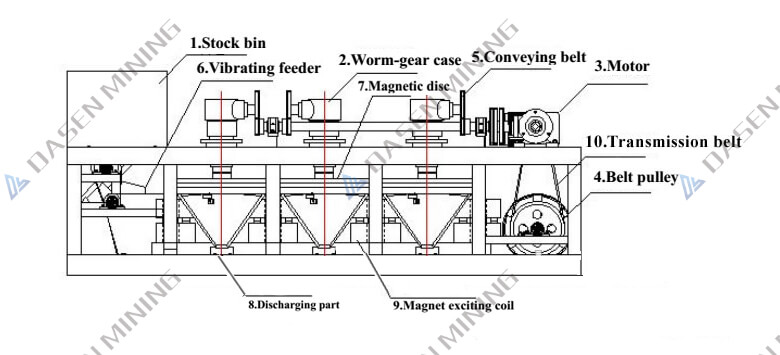

Key components include a mineral feeding mechanism, a weak magnetic roller, a transmission system, a conveyor wheel, an electromagnetic assembly, and a supporting frame. The electrical control system encompasses control, voltage regulation, rectification, and instrumentation functions.

Three-Disc Belt Magnetic Separator

The three-disc belt magnetic separator is a specialized equipment designed for the efficient separation of fine-grained (2-3mm) weak magnetic minerals and rare earth ores. Available in CP-500 and CP-600 models, this separator employs a dry process to effectively separate diverse magnetic minerals.

By precisely adjusting the excitation current of the discs, operators can tailor magnetic field intensities to accommodate varying mineral magnetic properties, achieving single-pass separation of multiple minerals. This technology finds extensive application in the processing of ilmenite, monazite, tungsten, tin, tantalum, niobium ores, and other mineral combinations.

Magnetic Separator Features

- Adjustable magnetic field strength: Optimizes separation efficiency based on raw material characteristics.

- High magnetic field intensity: Achieves a powerful magnetic field of 2W Gauss.

- Efficient and durable: Delivers superior separation performance and extended lifespan.

- Versatile separation: The three-disk design enables simultaneous separation of strongly magnetic, weakly magnetic, and non-magnetic minerals in dry environments, making it ideal for regions with limited water resources.

- Modular construction: Comprises feeding, transmission, and magnetic field components for efficient assembly and maintenance.

- Advanced control system: Incorporates power supply, control, rectification, and operational indicators for precise operation.

Operating Instructions:

1. Screen the dry material and feed particles with a size ≤2mm into the hopper.

2. Adjust the spacing of the magnetic disc based on the ore type.

3. Activate the console by switching on the power supply.

4. Initiate the motor and the magnetic switch.

5. Open the feeding valve to supply material to the conveyor belt.

6. Cease feeding before machine shutdown.

| Capacity | 600-1000kg/h | Magnetic Pan Qty | 3 piece | Magnetic Pan Rotary Speed | 36r/min |

| Magnetic Field Intensity | 18000 Gauss | Power Supply | 380v | Feeding Width | 600mm |

| Raw Material Size | ≤2mm | Motor Power | 2.2kw | Dimension | 3100*770*1200mm |

| Magnetic Pan Diameter | 600mm | Direct-current Power | 3KVA | Weight | 2100kg |

Dasen News

Our high-performance Three-Disc Electromagnetic Separator is now on its way to Nigeria. This innovative machine utilizes dry separation technology to efficiently recover tin, tantalum, and other valuable minerals, optimizing mining operations.

We can provide you with more information about Ta&Nb/Coltan/ Tin Ore Processing Plant. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]