Description

Name: Self-unloading permanent magnet iron remover, Permanent magnet separator

Adaptable bandwidth: 500~2400mm

Magnetic field strength: 50mt~150mt

Motor power: 1.5~7.5kw

Iron removal weight: 0.1~35kg

Dry and wet type: dry iron remover

Equipment model: RCYD series

Scope of application: The process is used to remove iron from any material before the crusher and on the conveyor belt, and can be applied in harsh environmental conditions.

Structure: Mainly composed of frame, cycloidal pinwheel reducer, chain, sprocket, roller, and steel belt with a scraper.

The self-unloading Permanent magnet separator is an advanced version of the RCYD series, incorporating an automated iron discharge mechanism. Constructed from corrosion-resistant materials, this high-capacity unit operates continuously without power loss, ensuring efficient and uninterrupted iron removal. Primarily designed for materials with high iron content, it effectively captures ferromagnetic contaminants, which are subsequently discharged via the integrated mechanism.

When combined with belt or vibrating conveyors, this equipment adeptly removes ferromagnetic impurities weighing between 0.1 and 30 kg from bulk materials. Beyond enhancing material purity, it safeguards grinding and crushing equipment from damage by preventing iron-related wear. Additionally, the system can recover valuable ferromagnetic substances.

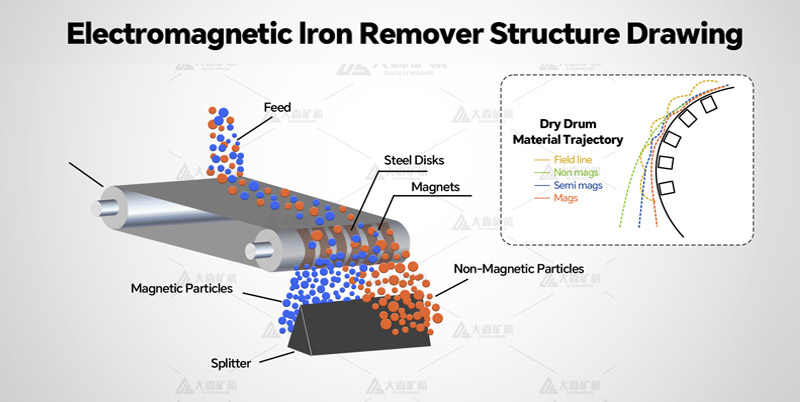

Working Principle

A self-unloading permanent magnet iron remover efficiently extracts ferromagnetic impurities from granular materials as they pass directly over its surface. The device is capable of removing approximately 0.1 to 0.36 kilograms of ferromagnetic contaminants per pass. As the magnetic material moves through the non-magnetic zone, the attached iron particles are scraped off by a belt and deposited into a collection bin, ensuring continuous and automated iron removal.

Advantages:

- Optimized Magnetic System: Leveraging advanced computer simulation, the system boasts a perfectly engineered double magnetic pole structure. This configuration delivers exceptional magnetic field strength, a steep gradient, and powerful suction capabilities.

- Durable Magnetic Source: Employing high-performance NdFeB magnets, the system guarantees a superior magnetic energy product while exhibiting exceptional resistance to demagnetization. Even after eight years of operation, demagnetization remains below 5%.

- Robust Drum Design: Featuring a waist drum structure, automatic deviation correction, fully sealed bearing housing, and superior sealing performance, the drum is engineered to withstand demanding environments.

- Continuous Operation: Automatic iron removal ensures uninterrupted belt operation over extended periods without requiring maintenance.

- Efficient Control: Integration of the control system with the belt conveyor facilitates both on-site manual operation and centralized control for optimal management.

| Model | Adaptive bandwidth

mm |

Rated lifting height

h=mm |

Material thickness

≤mm |

magnetic field intensity

≥mT |

Driving power

≤KW |

weightkg | Overall dimension

mm |

||||

| A | B | C | E | D | |||||||

| RCYD(C)-5 | 500 | 150 | 80 | 60 | 1.5 | 750 | 1900 | 735 | 935 | 753 | 950 |

| RCYD(C)-6 | 600 | 175 | 120 | 60 | 1.5 | 920 | 2050 | 780 | 1030 | 753 | 1100 |

| RCYD(C)-6.5 | 650 | 200 | 150 | 70 | 2.2 | 1200 | 2165 | 780 | 1080 | 888 | 1200 |

| RCYD(C)-8 | 800 | 250 | 200 | 70 | 2.2 | 1400 | 2350 | 786 | 1280 | 1088 | 1300 |

| RCYD(C)-10 | 1000 | 300 | 250 | 70 | 3.0 | 2120 | 2660 | 920 | 1550 | 1335 | 1400 |

| RCYD(C)-12 | 1200 | 350 | 300 | 70 | 4.0 | 3350 | 2900 | 970 | 1720 | 1515 | 1550 |

| RCYD(C)-14 | 1400 | 400 | 350 | 70 | 4.0 | 4450 | 3225 | 1050 | 1980 | 1755 | 1800 |

| RCYD(C)-16 | 1600 | 450 | 400 | 70 | 5.5 | 6200 | 3420 | 1180 | 2210 | 1850 | 1950 |

| RCYD(C)-18 | 1800 | 500 | 450 | 72 | 7.5 | 8100 | 3580 | 1210 | 2450 | 2130 | 2200 |

| RCYD(C)-20 | 2000 | 550 | 500 | 72 | 11 | 9700 | 3800 | 1300 | 2700 | 2410 | 2400 |

Note:

(1) This device exhibits a magnetic intensity exceeding the national standards T1, T2, and T3, with measured values surpassing 90mT, 120mT, and 150mT, respectively.

(2) Equipment for each model can be customized to meet specific user requirements.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]