Description

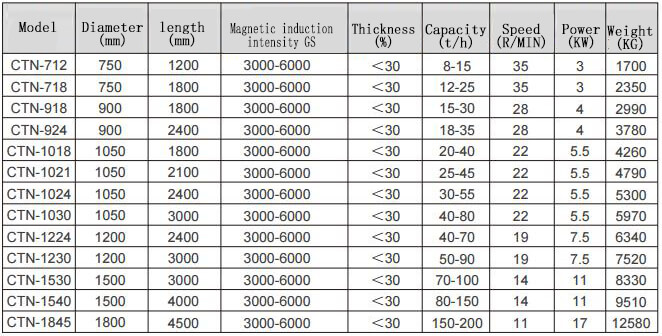

Product Name: Wet Magnetic Separator, wet drum magnetic separator

Feeding particle size: 0-5mm

Feeding concentration: 0-50%

Production capacity: 0.25-120T/H

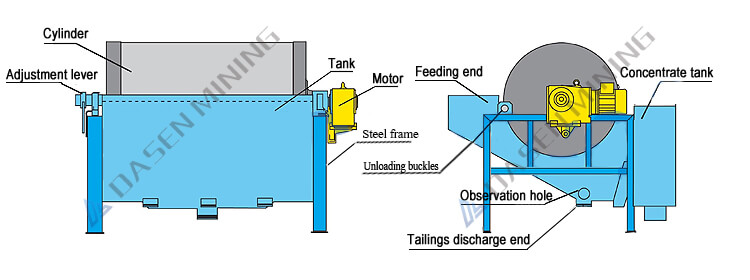

Structure: Wet permanent magnet drum magnetic separator is mainly composed of a cylinder, roller, brush roller, magnetic system, tank body and transmission part.

High-Performance Permanent Magnet Drum Separator

The permanent magnet drum separator is a high-intensity wet magnetic separation device incorporating powerful neodymium-iron-boron (NdFeB) and ferrite magnet blocks. This robust magnetic system offers a deep magnetic field with exceptional resistance to demagnetization.

Designed for high throughput, the separator effectively handles fluctuations in production while delivering precise separation results. Its versatility finds applications across various industries, including wood processing, mining, ceramics, chemicals, food, and more. Common uses encompass iron removal from coal, non-metallic minerals, and construction materials.

This model’s widespread adoption underscores its status as an industry standard for efficient and reliable magnetic separation.

Magnetic Separator Classification

Magnetic separators are primarily categorized into two types: permanent magnetic separators and electromagnetic magnetic separators.

Permanent Magnetic Separators Typically employing ferrite materials or rare earth magnetic steel, permanent magnetic separators generate an average magnetic induction intensity ranging from 80 to 400mT on the magnetic cylinder’s surface. Advancements in technology have led to the development of roll-shaped permanent magnetic separators capable of achieving a remarkable magnetic field intensity of 1650mT, currently the highest recorded for this type of separator.

Electromagnetic Magnetic Separators Renowned for their superior magnetic flux, electromagnetic magnetic separators generally outperform their permanent magnet counterparts. However, their higher power consumption, susceptibility to damage, and complex maintenance requirements have prompted cost-conscious businesses to opt for permanent magnet alternatives.

Downstream Permanent Magnet Drum Separators

- Co-current type: Pulp flows in the same direction as the drum, primarily used for coarse mineral separation (6-0mm) with low recovery rates and high impurity content.

- Counter-current type: Pulp flows opposite to the drum’s direction, resulting in higher recovery rates due to the distance between the tailings discharge and feed points. However, this configuration often leads to lower product purity.

- Semi-countercurrent type: Combines elements of both co-current and counter-current designs, with pulp flowing in the same direction as half the drum and opposite to the other half. This configuration promotes efficient mineral separation by dispersing the pulp and aligning the pulp movement with the magnetic force.

Wet Drum Magnetic Separator Working Principle:

Ore slurry is introduced into the tank through a feed box, where the force of the feed water spray propels loose ore particles into the feed area. Within this area, magnetic particles are subjected to the magnetic field, causing them to aggregate into chains or clusters.

The cylinder’s magnetic poles are arranged alternately and remain fixed during operation. As the magnetic chains or clusters rotate, the alternating magnetic field induces a stirring effect, separating non-magnetic minerals (gangue) from the magnetic material. The magnetically attracted chains or clusters adhere to the cylinder’s surface until they reach the area of weaker magnetic force at the discharge end. Here, flushing water propels the concentrate into a dedicated tank.

Non-magnetic or weakly magnetic minerals remain suspended in the slurry and are discharged as tailings.

Scope of Application and Product Features:

Wet magnetic separation is effectively applied to the processing of magnetite, pyrrhotite, roasted ores, and ilmenite with particle sizes below 3mm. Additionally, this method is utilized for iron removal in coal, non-metallic ores, and building materials.

Our magnetic separators employ either ferrite or rare earth magnetic steel, achieving an average magnetic induction intensity of 100-600mT on the cylinder surface. To accommodate diverse user requirements, we offer magnetic separation configurations including concurrent, semi-countercurrent, and countercurrent systems.

Renowned for their simple structure, high processing capacity, user-friendly operation, and minimal maintenance needs, our magnetic separators are a reliable choice for various industrial applications.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]