Gravity Separation and Magnetic Separation in Manganese and Chromium

Gravity separation and magnetic separation are two common methods used in the mineral processing industry to concentrate valuable minerals from their associated ores. These techniques exploit the differences in density and magnetic properties of minerals to achieve effective separation.

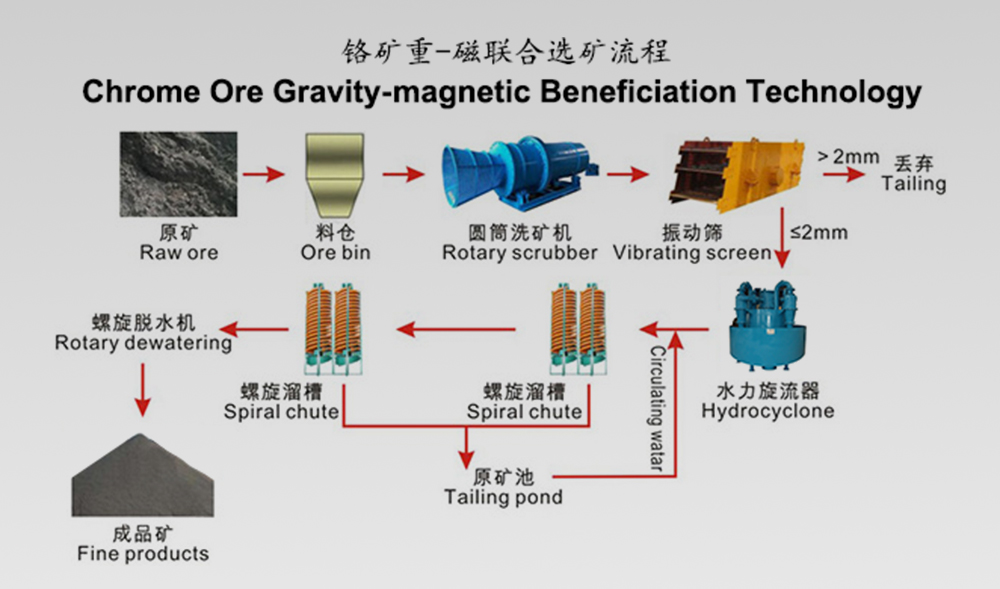

Gravity Separation: This method leverages the density disparity between chromium minerals and gangue. Common gravity separation equipment includes shaking tables, jigs, spiral concentrators, and centrifugal concentrators. After being ground to an appropriate size, Chromium ore is often subjected to gravity separation to obtain a rough concentrate.

Magnetic Separation: Following gravity separation, a strong magnetic separator is employed to further enhance the concentration of magnetic chromium minerals. The magnetic properties of these minerals allow them to be attracted to a magnetic field, separating them from non-magnetic impurities.

Manganese Oxide Ore Processing

Gravity Separation: Similar to chromium ore, manganese ore benefits from gravity separation due to the density contrast between manganese minerals and gangue. The process involves grinding the ore to liberation size and then subjecting it to gravity separation using equipment such as shaking tables or spiral concentrators.

Magnetic Separation: After gravity concentration, a strong magnetic separator is used to remove magnetic impurities from the manganese concentrate. This step is crucial to obtain a high-purity manganese product.

Locating Chromium and Manganese Ores

Geological Exploration: Geological exploration involves mapping, sampling, and analyzing rocks and minerals to identify potential ore deposits. Geologists use various techniques, including remote sensing, geophysical surveys, and geochemical analysis, to locate areas with high mineral potential.

Ore Analysis: Once a mineral deposit is discovered, ore samples are subjected to detailed analysis. This includes chemical analysis to determine the mineral composition and physical testing to assess properties such as density, hardness, and magnetic susceptibility.

Conclusion

Gravity separation and magnetic separation play vital roles in the processing of chromium and manganese ores. By exploiting the physical properties of these minerals, these techniques enable the efficient extraction of valuable metals from their ores. Geological exploration and ore analysis are essential steps in the discovery and evaluation of mineral deposits.

If you have any questions about the above content or want to know more info, please contact the online service or submit your message.

Whatsapp:+86 133 1927 7356

Email:[email protected]