Factors affecting flotation include grinding fineness, slurry density, aeration volume, flotation time, etc. It is recommended that customers analyze ore and perform flotation experiments before formally building the plant, through which the actual quantities of these influencing factors can be determined.

In the general gold ore flotation process, the flotation reagents that need to be used include collectors, foaming agents, regulators, etc. The most common collectors are xanthate and black agents; commonly used foaming agents are No. 2 oil, eucalyptus oil, etc.; regulators can be divided into inhibitors and activators. In gold ore flotation, the inhibitor is used to reduce the floatability of some minerals, and the function of the activator is to make a certain mineral easy to absorb the sorbent and float up.

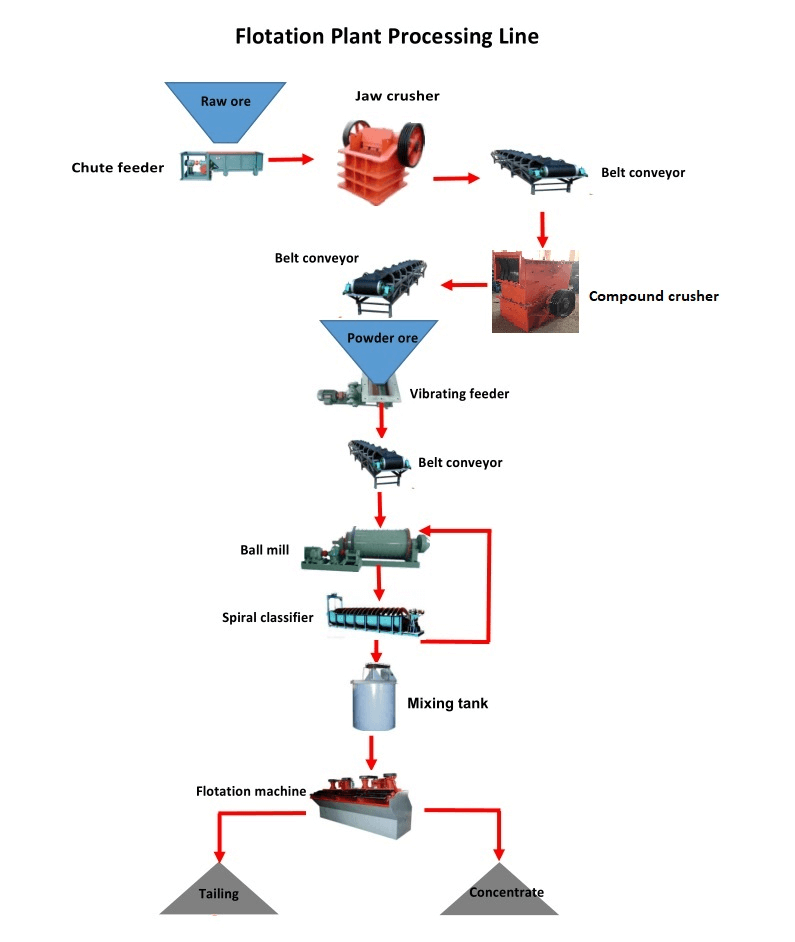

The above flow is about gold flotation process, which is widely used in Africa gold miner, and which is higher recovery rate than gravity separating but lower recovery rate than gold CIP/CIL separating.

Generally, flotation processing needs to use chemicals, which will cause the influence to environment.

In gold ore flotation process, flotation machines are very important, besides, the same important part is the flotation technique and chemicals using, etcs.

Gold flotation can recovery smaller size gold than gravity separating. So if your raw gold ore has low grade and smaller size, maybe you can consider use the flotation separating.