Can centrifugal separation be applied to jigging gravity separation?

In the last issue, we talked about the application of the centrifugal gravity separation process in the flotation process. We will discuss how centrifugal gravity separation can be applied to jigging gravity separation in this issue.

Jigging gravity separation is an effective method for processing coarse and medium-sized ores. When processing metal ore, the upper limit of the feeding particle size can reach 30-50mm, and the lower limit of the recovered particle size is 0.2-0.074mm. Due to the limitation of the lower limit of the recovered particle size, the jig cannot be used for the recovery of fine-grained minerals.

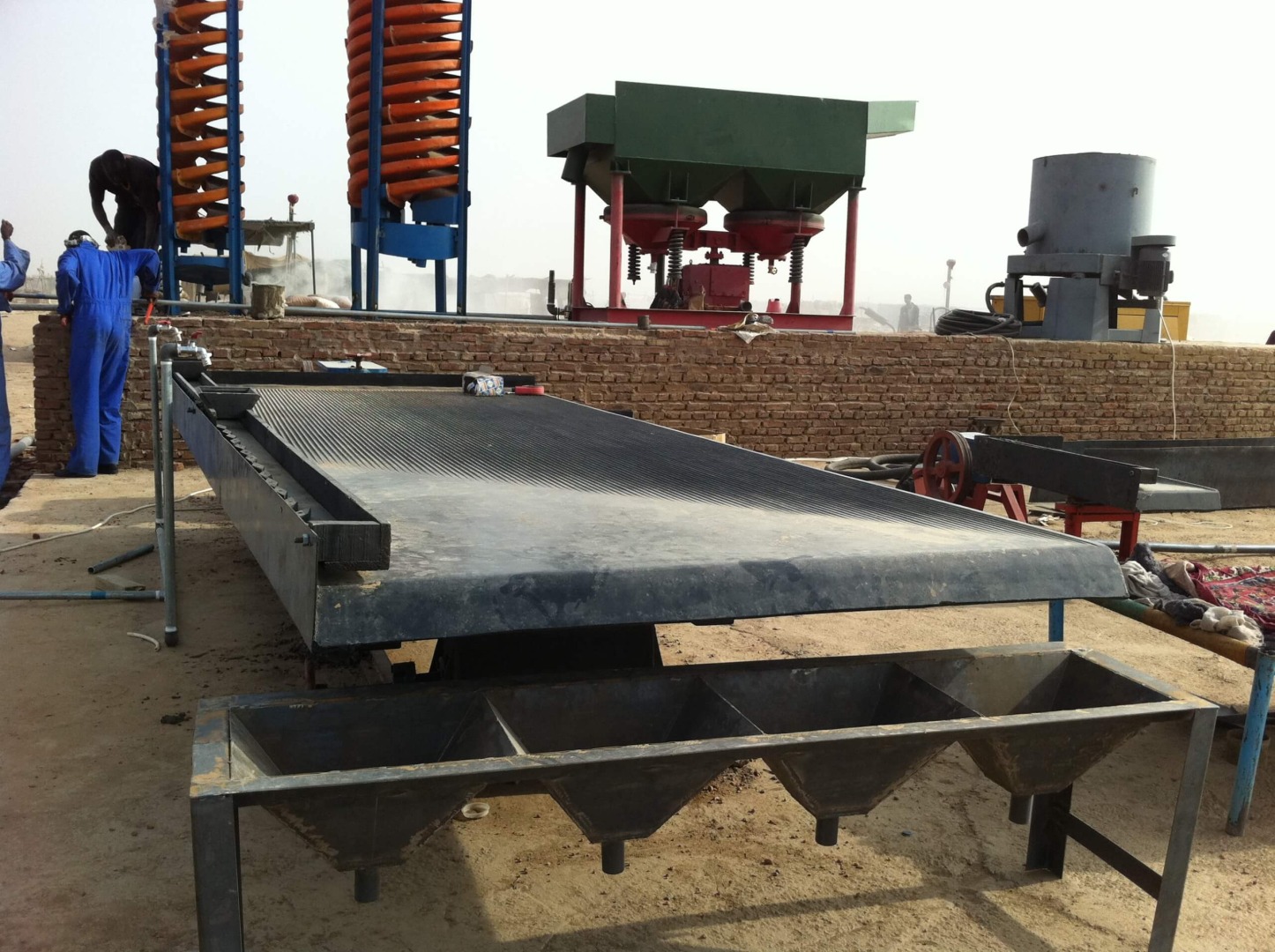

This results in high metal content in the fine fraction of the tailings of the jig machine. The overall recovery rate is lowered. At the same time, due to the large processing capacity of the jig machine, the corresponding tailings volume is also large. The recovery of the fine-grained part of the valuable metals can only be considered by shaking or flotation.

Dasen Mining’s centrifugal gravity separation process utilizes cyclones to separate particles as small as 2 mm but up to 400 mesh via centrifugal gravity acceleration. It can effectively enrich fine-grained materials and the daily processing capacity is as high as 600-800 tons. It can effectively solve the current situation that the fine-grained materials of the jig cannot be recovered.

One centrifugal separation with a 6-8 shaking table can process 6-800 tpd of jig tailings, ensuring the recovery of fine-grained metals. Compared with the jig tailings only recovered by the shaking table, it can save 38% of electricity, 86% of water, 85% of the workshop, and 66% of labor every day. The cyclone centrifugal gravity separation process has a large processing capacity and a wide range of particle sizes and is matched with selection processes such as shaking table and flotation. The production process is efficient, energy-saving and environmentally friendly. Gravity beneficiation processes can use it in a variety of ways, and it is the first choice for a variety of wastes and tailings.

All mine owners who are facing the pressure of environmental protection and energy consumption can consider our centrifugally beneficiation equipment. For more knowledge about mineral processing, please follow us. or contact us:

Whatsapp:+86 133 1927 7356

Email:[email protected]