Zinc Testing: A Key Step in the Gold Extraction Process

Zinc testing is an essential process in the extraction of gold from mineral powder or ore. This comprehensive guide provides detailed insights into conducting zinc testing for gold extraction.

Materials Needed:

- Mineral powder or ore

- Water

- Chemicals (sodium cyanide or environmentally friendly alternatives)

- Zinc wire or zinc foil

- Dilute sulfuric acid

- Concentrated sulfuric acid

Procedure:

-

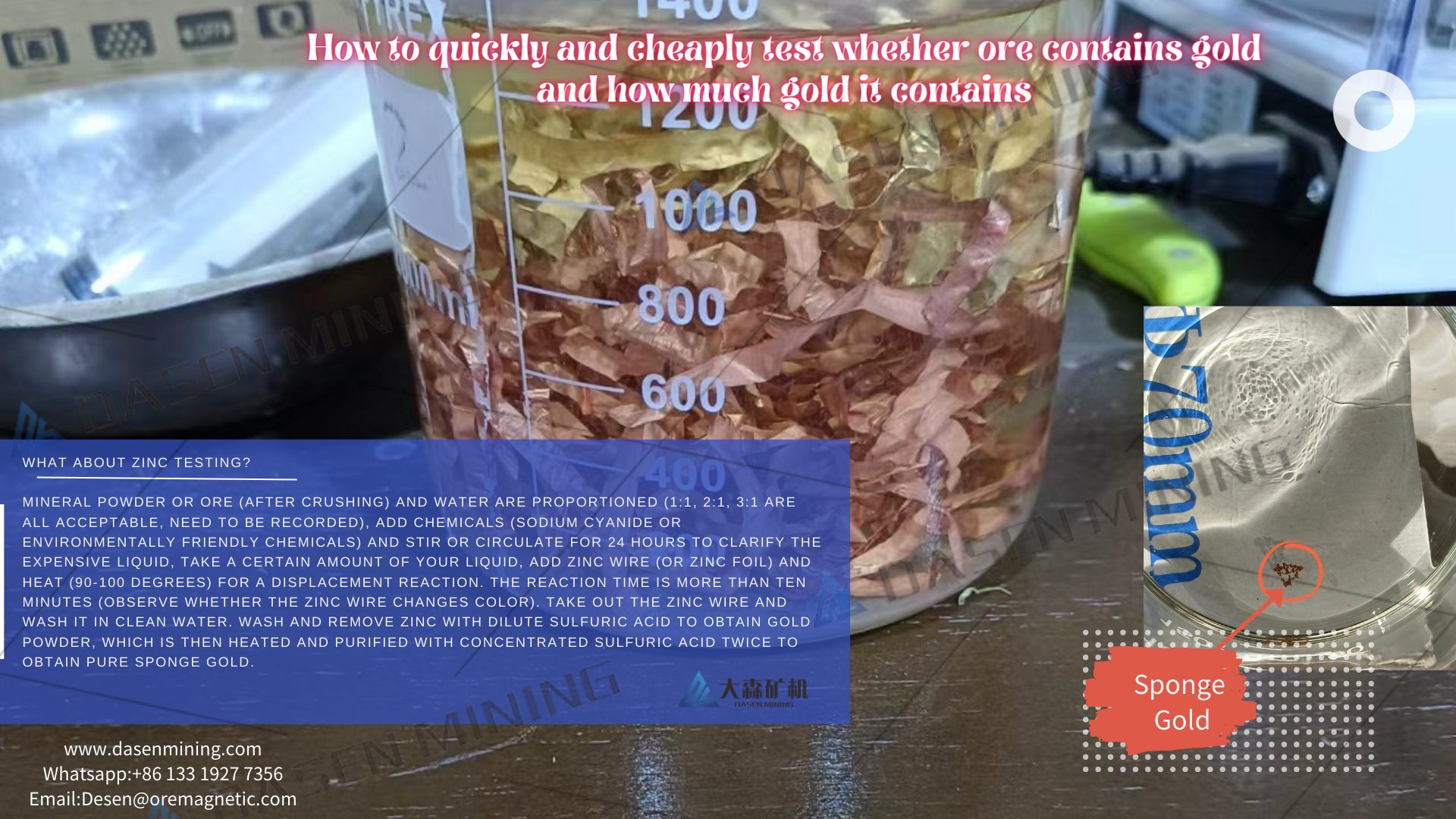

Proportioning: Combine mineral powder or ore and water in a ratio of 1:1, 2:1, or 3:1. It’s crucial to record the specific proportions used for accurate documentation.

-

Chemical Addition: Add the appropriate chemicals, such as sodium cyanide or environmentally friendly alternatives, to the mixture.

-

Stirring or Circulation: Stir or circulate the mixture for 24 hours to clarify the expensive liquid, ensuring thorough blending of the components.

-

Sample Collection: Take a certain amount of the liquid mixture for further testing and analysis.

-

Displacement Reaction: Add zinc wire or zinc foil to the collected liquid and heat the mixture to a temperature range of 90-100 degrees. The zinc undergoes a displacement reaction during this process.

-

Reaction Observation: Allow the displacement reaction to occur for more than ten minutes, observing any changes in the color of the zinc wire, which serves as an indicator of the reaction progress.

-

Zinc Recovery: After the displacement reaction, remove the zinc wire and wash it in clean water to remove any impurities.

-

Gold Powder Extraction: Wash and remove the zinc from the zinc-coated wire using dilute sulfuric acid, resulting in the extraction of gold powder from the solution.

-

Purification: Heat the obtained gold powder and purify it with concentrated sulfuric acid twice to obtain pure sponge gold.

Importance of Zinc Testing:

Zinc testing plays a crucial role in the process of gold extraction from mineral powder or ore. By facilitating a displacement reaction with zinc, the presence and quantity of gold in the sample can be determined. Additionally, the extraction of gold powder and its subsequent purification lead to the obtainment of pure sponge gold, which is valuable for various industrial and commercial applications.

Environmental Considerations:

It’s important to note that the use of environmentally friendly chemicals in the testing process aligns with sustainable and responsible practices. By opting for these alternatives, the environmental impact of the extraction process can be minimized.

Conducting zinc testing for gold extraction involves a series of meticulous steps aimed at accurately assessing the presence and quality of gold in mineral powder or ore. The utilization of zinc in the displacement reaction, followed by the extraction and purification of gold powder, is integral to the overall process of obtaining pure sponge gold.

This comprehensive guide serves as a valuable resource for individuals and organizations involved in gold extraction and refining, emphasizing the importance of meticulous testing and environmentally conscious practices in the pursuit of valuable gold resources.

Whatsapp:+86 133 1927 7356

Email:[email protected]