What kinds of flotation reagents are there?

In the realm of mineral processing, flotation is a vital technique employed to selectively separate minerals based on their surface properties. The effectiveness of flotation hinges on the judicious use of flotation reagents, which can significantly influence the floatability of various minerals. These reagents act by modifying the surface characteristics of minerals, making them either more or less hydrophobic, thereby facilitating their separation from the ore pulp.

Classification of Flotation Reagents

Flotation reagents can be broadly classified into three primary categories based on their functions:

1. Collectors

Collectors are organic substances that selectively adhere to the surface of specific minerals, rendering them hydrophobic. This hydrophobic nature allows the mineral particles to attach to air bubbles and float to the surface. Collectors can be further categorized based on their ionic nature:

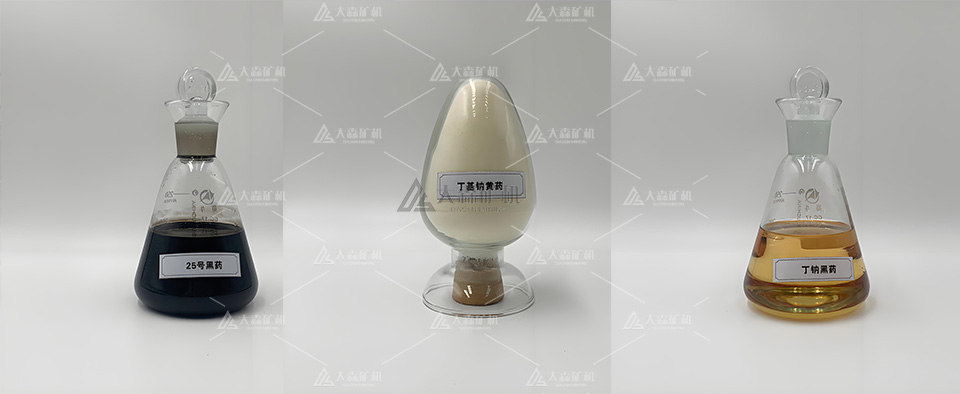

- Non-ionic collectors: Kerosene, diesel, xanthate, hydrocarbyl thiocarbamate

- Anionic collectors: Xanthate, black medicine, oleic acid, sodium hydrocarbyl sulfate

- Cationic collectors: Mixed amine, lauric acid

2. Frothers

Frothers are surface-active agents that promote the formation and stabilization of fine-sized air bubbles at the water-air interface. These stable bubbles are essential for the flotation process as they provide a surface for the hydrophobic mineral particles to attach. Frothers can be classified into:

- Surfactants: Butyl ether oil, terpineol oil, mixed alcohol, ether alcohol oil

- Non-surfactants: Diacetone alcohol oil

3. Modifiers

Modifiers are reagents that can alter the interaction between collectors and minerals, adjust the properties of the ore pulp, and improve the selectivity of the flotation process. They can be further divided into:

- Activators: Promote the interaction between collectors and minerals, enhancing the floatability of certain minerals. Examples include copper sulfate and sodium sulfide.

- Inhibitors: Weaken the interaction between collectors and minerals, reducing the floatability of specific minerals. Examples include sodium sulfide, water glass, tannin, starch, etc.

- pH adjusters: Modify the pH of the ore pulp to create a favorable environment for the flotation of desired minerals and an unfavorable environment for undesired minerals. Examples include dilute sulfuric acid, sodium hydroxide, and sodium bicarbonate.

- Dispersants and flocculants: Control the dispersion, agglomeration, and flocculation of fine mud particles in the slurry. Examples of flocculants include lime, alum, starch, bone glue, polyacrylamide, and polyoxyethylene. Examples of dispersants include water glass, soda, and various polyphosphates.

Conclusion

Flotation reagents play a pivotal role in the successful separation of minerals through the flotation process. By understanding the different types of flotation reagents and their specific functions, it is possible to optimize the flotation process for various mineral ores and achieve the desired separation results.

We can provide you with more information about tailings recycling. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]