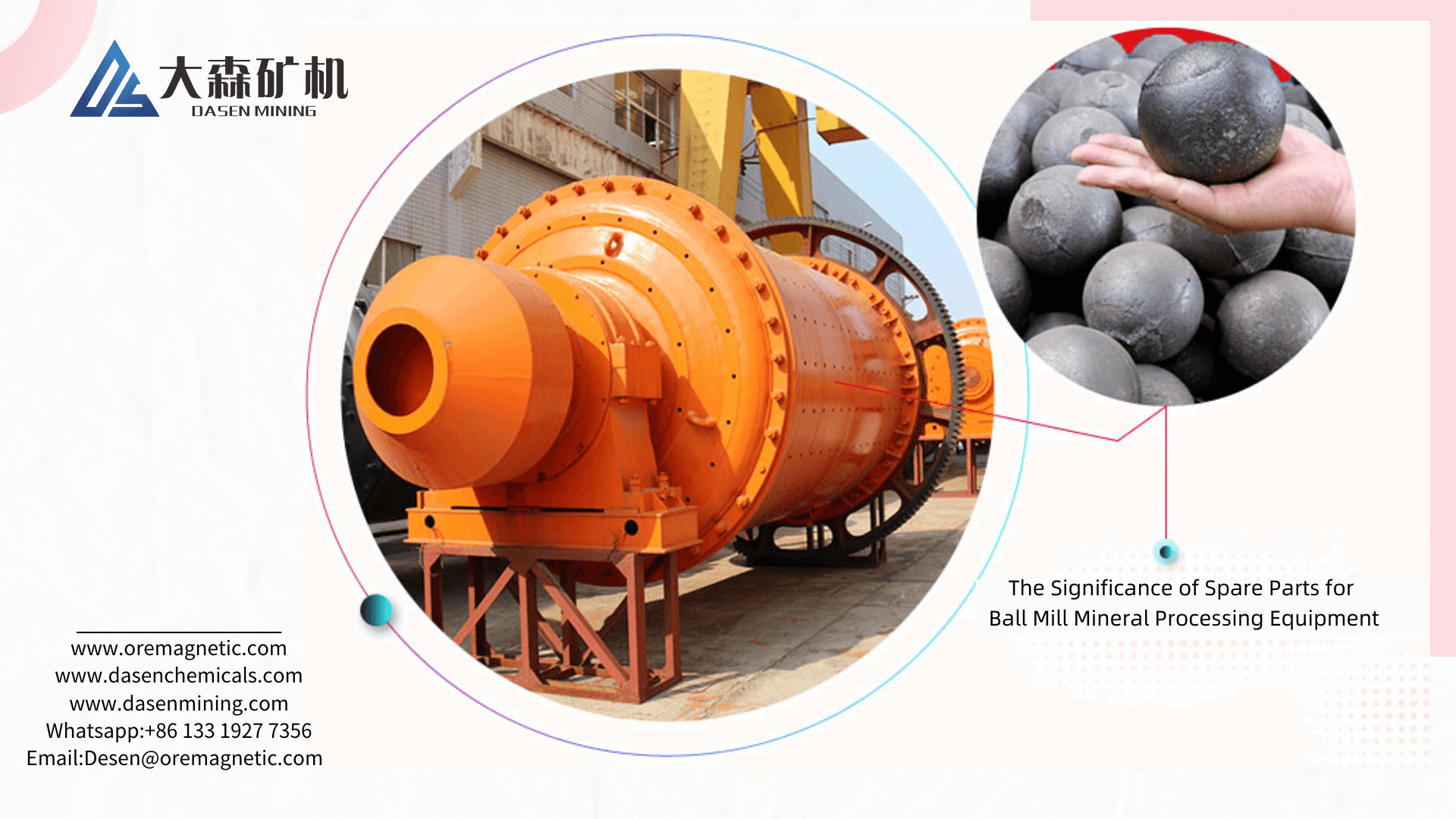

Why Genuine Spare Parts Are Crucial for Ball Mill Mineral Processing Equipment

The Role of Spare Parts in Ball Mill Mineral Processing Equipment: Spare parts play a vital role in the smooth operation and maintenance of ball mill mineral processing equipment. Their significance can be highlighted in the following aspects:

1.1 Maintenance and Repair: Regular maintenance and timely replacement of vulnerable parts are essential for ensuring the uninterrupted functioning of ball mill equipment. Spare parts enable swift repairs, minimizing downtime, and avoiding costly production interruptions.

1.2 Equipment Longevity: The utilization of genuine spare parts ensures compatibility and longevity of the equipment. These parts are specifically designed to meet the original equipment manufacturer’s specifications, guaranteeing seamless integration and optimized performance.

1.3 Enhanced Performance: Spare parts tailored for ball mill equipment enhance its overall performance. Inadequate or low-quality parts can compromise the grinding efficiency, resulting in suboptimal outputs, increased energy consumption, and decreased product quality.

1.4 Safety and Reliability: Authentic spare parts ensure the safety and reliability of ball mill mineral processing equipment. The usage of non-genuine or substandard parts may jeopardize the safety of personnel and lead to equipment malfunction or failure, posing significant risks to both individuals and the environment.

Competitive Advantages of Reputable Manufacturers and Suppliers: Choosing a reputable manufacturer and supplier for spare parts is crucial to ensuring product quality, availability, and competitive pricing. Leading manufacturers typically offer the following key advantages:

2.1 Quality Assurance: Prominent manufacturers adhere to strict quality control measures and production standards to deliver high-quality spare parts. They employ advanced manufacturing techniques and conduct comprehensive testing and inspections, ensuring that each component meets or surpasses industry standards.

2.2 Extensive Product Range: Established manufacturers provide a wide range of spare parts for ball mill equipment, catering to various models and specifications. This ensures that customers can find the specific parts they require, reducing the risk of equipment downtime due to unavailability.

2.3 OEM Expertise: Reputable manufacturers possess in-depth knowledge of original equipment manufacturer (OEM) specifications. They understand the intricate details of ball mill equipment, enabling them to produce spare parts that precisely match the unique requirements of each machine.

2.4 Prompt Delivery: Timely delivery of spare parts is critical for minimizing equipment downtime. Trusted manufacturers maintain sufficient inventory levels and efficient logistics networks to ensure prompt delivery, reducing the impact of unforeseen breakdowns on production schedules.

2.5 Competitive Pricing: Competitive pricing is a vital factor when selecting a supplier for spare parts for ball mill mineral processing equipment. Reputable manufacturers comprehend market dynamics and strive to offer competitive prices without compromising quality. They optimize cost structures through expertise, economies of scale, and efficient production processes, providing customers with cost-effective solutions.

Whatsapp:+86 133 1927 7356

Email:[email protected]