Description

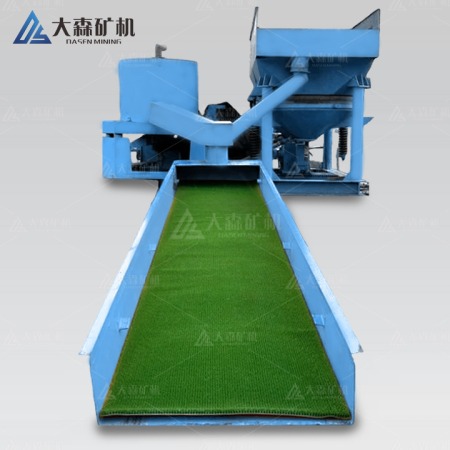

The mobile gold ore washing plant utilizes an eccentric shaft circular vibrating screen. To adjust the amplitude, a cylindrical eccentric shaft exciter and eccentric block are employed. The vibrator is strategically positioned on the side plate of the drying box and is driven by a triangular belt.

Capacity: 50-500 Tons / Hour;

Feeding: Dumper, Excavator Or Loader;

The Mobile Gold Ore Washing Plant processes ore through a series of stages. Coarse materials are screened out and discharged directly, based on the specific ore characteristics. Finer materials undergo further processing using equipment such as centrifuges, chutes, peristaltic chutes, vibrating chutes, and gold separation devices. This multi-stage approach ensures efficient recovery of gold from the ore.

Features of a Mobile Gold Ore Washing Plant

A mobile gold ore washing plant is designed with several key features to optimize gold recovery:

- Enhanced Screening Efficiency: The plant incorporates adjustable vibration rates, high-frequency operation, multi-layer screening, and a large inclination structure to achieve superior screening rates. These features ensure that even fine gold particles are effectively captured.

- Quiet and Reliable Operation: Engineered for low noise levels and stable performance, this equipment minimizes disturbances during operation and ensures long-term reliability.

- Easy Maintenance: With a simple structure, maintenance and servicing are quick and convenient, reducing downtime and increasing operational efficiency.

- High Processing Capacity: The plant is designed to handle large volumes of ore, making it suitable for various scale operations.

- Superior Gold Recovery: The optimized design and processes employed in this plant result in exceptional gold extraction rates,

Whatsapp:+86 133 1927 7356

Email:[email protected]