Description

Integrated Trommel gold washing machine Capacity: 3-500 tons/hour, customized processing according to demand;

It’s suited for Monomer gold recovery for placer gold and vein ore

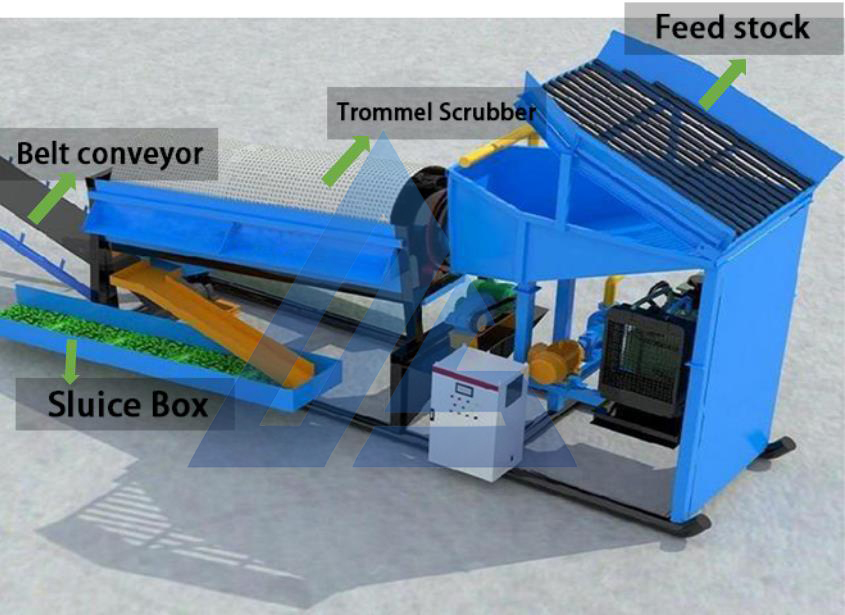

Structure: Ore bin – screen – clay soil washing – screen – chute – base, multiple flushing systems, high-pressure water guns, etc.

Power: generator set or diesel engine. They are customized according to the actual situation of the mining area.

An integrated Trommel gold washing machine is ideally suited for excavator or forklift loading. A vibrating screen can be pre-installed to remove oversized waste rocks.

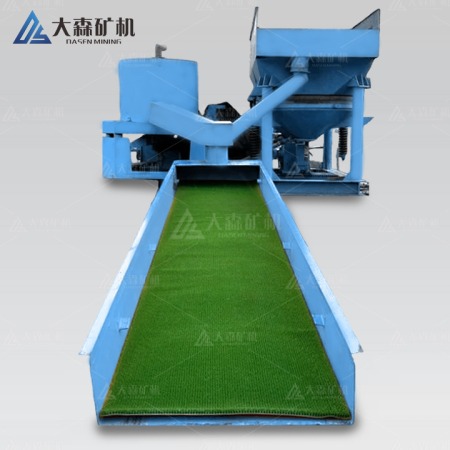

This equipment encompasses a hopper, ore washing, screening, and gold recovery stages. Material is loaded by an excavator or loader, and a high-pressure water spray within the hopper ensures even more distribution into the trommel washer. The machine removes mud, screens the material, and thoroughly cleans it, facilitating efficient gold separation and significantly enhancing recovery rates. To capture gold particles, including granular, capillary, and flake gold, we offer various gold recovery options such as vibrating sluice boxes, fixed sluice boxes, centrifugal concentrators, and shaking tables, tailored to the specific gold characteristics of the mining operation.

The integrated trommel gold washing machine can be equipped with either sleds or wheels for mobility. For larger models with substantial processing capacities, a sled base is necessary to support the equipment’s weight, as wheels may be insufficient.

There are three main types of integrated trommel gold washing equipment:

- Tracked mobile gold washing plant: This equipment is specially designed for complex terrains in mining areas. It has excellent off-road performance and can be dragged without deformation, making it ideal for mountainous and hilly areas.

- Tire-type sorting equipment: Suitable for areas with relatively flat terrain, this equipment is highly mobile and can be quickly deployed to the work site.

- Bilge/tubular substructure: Designed for areas with high mud content, this equipment has excellent passability, making it suitable for operation in muddy areas.

Features of the Integrated Trommel Gold Washing Machine

The integrated Trommel gold washing machine incorporates several advanced features to optimize gold recovery:

- Vibrating Feeder: Ensures consistent material feed for efficient processing.

- Sludge Handling: A declining cylinder is integrated at the separation screen’s inlet to effectively manage high sludge content, preventing blockages.

- Optimized Water Supply: A combined central and metering water supply system thoroughly cleanses the ore while safeguarding the outer washing screen from obstructions.

- Durable Separation Screens: Laser-cut from high-hardness manganese steel bars or high-strength iron plates, the separation screens are available in single or double layers to suit various mineral compositions.

- Versatile Gold Recovery: Depending on gold content and form, the machine can be equipped with drum chutes, peristaltic chutes, or water jacket centrifuges for optimal gold recovery.

- Automated Operation: Hydraulically operated, the machine eliminates manual labor, saving time and effort.

- Robust Construction: Built with cutting-edge wear-resistant technology, the compact and sturdy machine is easy to operate and maintain.

- Enhanced Gold Recovery: Combining the principles of fixed chutes and jigs, the machine overcomes fixed chute hardening issues and employs a dual-channel recovery system to capture fine, coarse, and flake gold, significantly boosting gold recovery rates.

- High Mobility: Easily transportable by excavators, forklifts, or trucks for flexible deployment.

- Recommended Capacity: Processes up to 10 tonnes per day.

Dasen Case:

Contact us today to find out more.

Whatsapp:+86 133 1927 7356

Email:[email protected]