Description

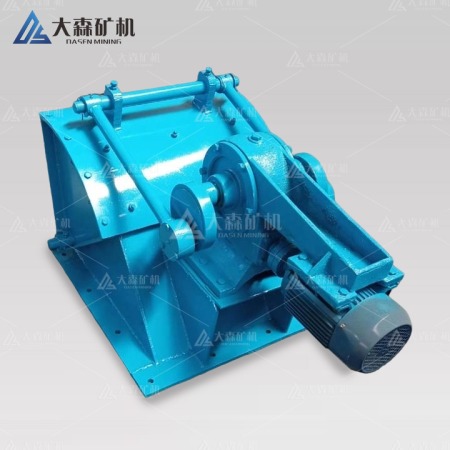

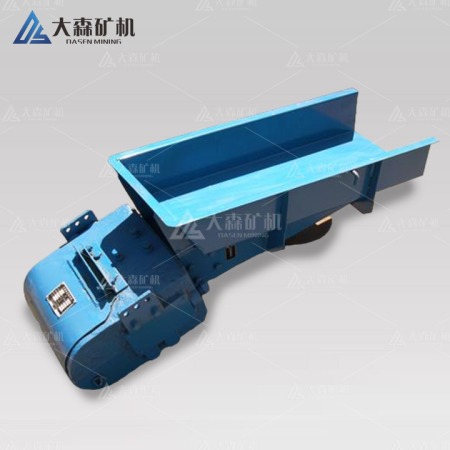

Name: pendulum feeder, Swaying Feeder, oscillating feeder, mining pendulum feeder

Motor power: 1.5-3kw

Feeding particle size: 35-50mm

Production capacity: 3-12t / h

Application: Pendulum feeders are suitable for transferring granular materials from storage tanks into a variety of receiving devices through funnels in beneficiation, coal, chemical, and other industries.

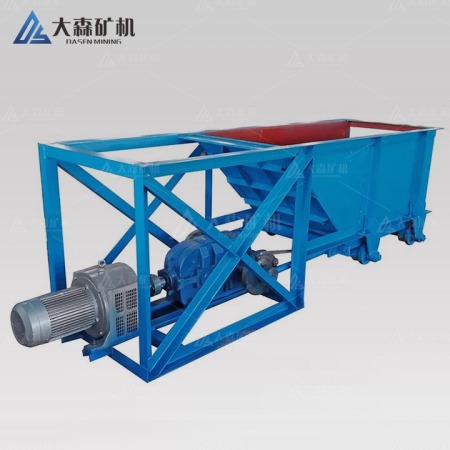

Swaying Feeder (also known as pendulum feeders) are essential auxiliary equipment in the transportation industry. Designed to accurately feed small, bulk materials in specific quantities, Swaying Feeders can handle particle sizes ranging from 35 to 100 millimeters. These versatile machines find widespread applications in factories, mines, and various industrial settings. They are commonly used to transfer bulk materials from silos or hoppers to a variety of receiving devices.

Swaying Feeder Working Principle

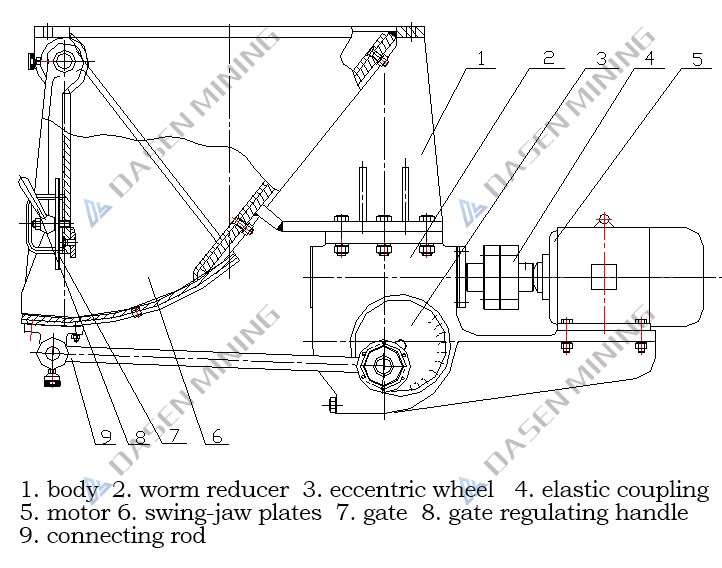

A Swaying Feeder operates through a power transmission system involving a motor, V-belt reducer, eccentric wheel, and connecting rod. This mechanism induces a swinging motion in the feeder’s bottom plate. Ore, stored in a bin above the feeder, enters the feeder’s interior and is discharged at a consistent rate through the outlet, ensuring uniform material feed to subsequent equipment like ball mills.

Swaying Feeders are versatile and find applications in various industries including abrasive processing. They excel at evenly and continuously conveying bulk and granular materials from storage to processing stages. As a critical component in sand and stone production lines, the Swaying Feeder reliably feeds crushing machinery while conducting initial material sizing.

Pendulum Feeder: A Versatile Solution for Fine Ore Feeding

The pendulum feeder, often referred to as a swinging feeder, is specifically designed for feeding fine-grained materials, typically with particle sizes less than 50mm. Due to its efficiency and reliability, it finds widespread application in the discharge of ore from grinding mills. The structural design of a standard 600 x 600 pendulum feeder is illustrated below.

Sector Gate Feeder

A sector gate is installed at the ore discharge outlet of the ore bin. The gate’s movement is controlled by a motor, which drives a worm gear to decelerate the gate’s motion. Further deceleration is achieved through an eccentric shaft and pull rod belt system. When the gate moves forward, the ore discharge port closes, while backward movement opens the port for ore unloading. This mechanism enables intermittent and even ore feeding.

While the tilting feeder boasts a simple design and easy operation, it suffers from poor accuracy, inconsistent ore feeding, and measurement challenges. In contrast, the sector gate feeder offers more precise control. The ore feeding capacity of the tilting feeder can be adjusted by modifying the eccentricity of the eccentric wheel.

By adjusting the eccentricity of the eccentric pin shaft on the eccentric wheel, the stroke length of the swing base plate can be altered. This modification enables a wide range of feed rate adjustments. Furthermore, by adjusting the height of the discharge gate and the size of the discharge port, precise control over the feed rate can be achieved.

| Model | Capacity(m3/h) | Maximum feeding size

(mm) |

Eccentric distance

(mm) |

Swing speed(t/min) | Swing stroke

( mm) |

Motor

model |

Weight

(kg) |

| 400×400 | 12 | 35 | 0—85 | 47 | 0—170 | Y90S—4

1.1KW 1400r/min |

265 |

| 600×600 | 22 | 50 | 0—110 | 47 | 0—200 | Y90L—4

1.5KW 1400r/min |

613 |

Installation

Typically, the tilting feeder is installed beneath the silo with its discharge port aligned towards the feeder. A chute connects the feeding belt conveyor to the tilting feeder. Before initiating the tilting feeder, ensure the fuel tank is full and the reducer is filled with gear oil. Other components should be lubricated with grease. The oil cup requires replenishment with grease once per shift, and the reducer oil should be changed every six months. After adjusting the feed rate, securely tighten the fixing bolts to prevent alterations during operation.

Maintenance

- Regular inspections: Monitor the wear of moving components and consistently check the lubrication levels of all bearing reducers. Replace reducer oil every one to two months based on usage.

- Safety precautions: Avoid adjustments to the equipment while it is in operation. In case of malfunctions or hindered movement, immediately shut down the motor and address the issue after the machine has completely stopped.

- General upkeep: Maintain cleanliness both internally and externally.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]