Description

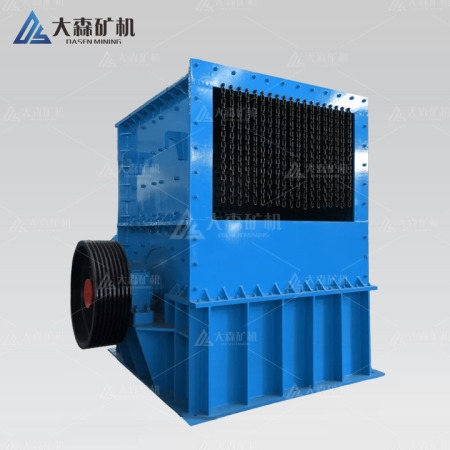

Name: Compound Crusher

Motor power: 11-160kw

Feed particle size: ≤1200mm

Production capacity: 5-280t/h

Scope of application: Widely used in mining, metallurgy, cement, sand making, and fine crushing of various materials with compressive strengths less than 150MPa.

The PwC series compound crusher is an innovative crushing machine developed by our company. Designed for efficient processing of medium-hard materials with a compressive strength up to 150 MPa, it finds wide application in the building materials, mining, metallurgy, and chemical industries.

Combining the strengths of impact and hammer crushers, this equipment boasts a robust design, reliable operation, and a high crushing ratio. It delivers consistent product size, high throughput, and low energy consumption while being easy to maintain. Unlike traditional two-stage crushing processes, the PwC series can handle coarse, medium, and fine crushing of limestone in a single operation. This eliminates the need for extensive civil engineering and equipment investments, making it an ideal solution for cost-effective material processing.

Working Principle:

A V-belt transmits power to the crusher rotor, which subsequently drives the hammer head at high speed. As material enters the crushing chamber, it is subjected to forceful impacts from the rapidly rotating hammerhead, resulting in initial size reduction. Large fragments are redirected towards the central support bar where repeated impacts from the hammer head further break them down into smaller pieces. These smaller particles are then propelled towards the lower section of the crusher. To achieve the desired particle size, oversize material undergoes additional crushing through contact with the tangential force of the hammerhead, allowing for simultaneous coarse, medium, and fine crushing in a single pass. Finally, the processed material is discharged through the sieve plate openings.

Key Features:

- Robust Construction: The machine body is welded using gas-shielded welding and vibration failure processes, ensuring exceptional strength and durability.

- Precision Components: Transmission parts are CNC-machined and undergo a quenching and tempering process for optimal toughness.

- Enhanced Wear Resistance: The hammer disc features a wear-resistant surface treatment and is crafted from high-toughness material. The hammer head is made of high-chromium alloy for superior wear resistance and tensile strength.

- Durable Materials: The sieve and guard plates are constructed from impact-resistant and wear-resistant alloys for extended lifespan.

- Optimized Performance: Improved aesthetics and enhanced internal components contribute to superior overall performance.

| Model | Max feeding Size(mm) | Discharging Size(mm) | Capacity (t/h) | Motor Power(kw) | Weight (t) |

| PWC600*400 | <200 | <0-40 | 10-15 | 11 | 1.5 |

| PWC800*600 | <300 | <0-40 | 15-20 | 18.5 | 2.8 |

| PWC900*600 | <400 | <0-40 | 20-30 | 37 | 3.7 |

| PWC1000*800 | <500 | <0-40 | 20-40 | 55 | 5.3 |

| PWC1000*1000 | <500 | <0-40 | 40-50 | 75 | 5.8 |

| PWC1000*1200 | <550 | <0-40 | 50-75 | 90 | 6.5 |

| PWC1100*1300 | <600 | <0-40 | 70-90 | 132 | 6.8 |

| PWC1200*1200 | <600 | <0-40 | 90-100 | 160 | 8.6 |

| PWC1200*1500 | <600 | <0-40 | 100-130 | 185 | 13 |

| PWC1400*1300 | <900 | <0-40 | 100-150 | 75*2 | 14.7 |

| PWC1400*1400 | <900 | <0-40 | 150-200 | 90*2 | 15 |

| PWC1500*1500 | <1000 | <0-40 | 200-270 | 110*2 | 18 |

| PWC1600*1600 | <1000 | <0-40 | 200-350 | 132*2 | 27 |

| PWC1800*1800 | <1200 | <0-40 | 350-400 | 160*2 | 39 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]