Description

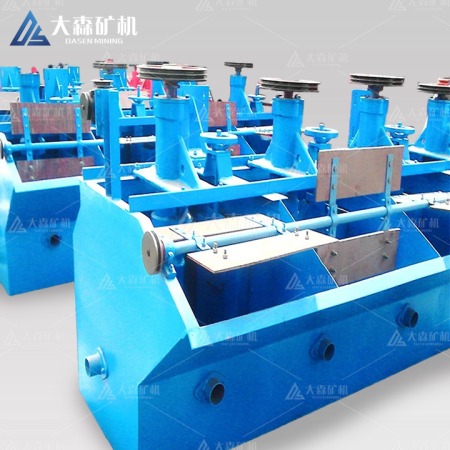

Name: Inflatable Type Sub aeration Flotation Machine, inflatable flotation device, BS-K Inflatable Flotation Cell

Tank volume: 2.8-24m³

Processing capacity: 0.4-20 m³/min

Scope of application: Select non-ferrous metals such as copper, zinc, lead, nickel, gold, etc., and can also be used for rough selection and selection of ferrous metals and non-metals.

The BS-K inflatable flotation device, also referred to as an inflatable mechanical stirring flotation machine, shares a similar design with the XCF/KYF flotation machine. Known for its robust performance, the device features a conical impeller section, radial stator path, and minimal wear for extended service life. Its powerful stirring action effectively prevents ore accumulation in the U-shaped groove body. The lightweight shaft components and stator integrated into the groove body simplify installation.

- Exceptional separation efficiency: The process generates small, evenly distributed bubbles, resulting in high enrichment ratios and recovery rates, making it ideal for fine-grained mineral separation.

- High precision and capacity: The system offers precise sorting capabilities and robust processing capacity.

- Simplified operation and maintenance: The machine features a simple design, easy maintenance, safe operation, and energy efficiency.

- Flexible automation: Through appropriate configuration, automated production can be readily achieved.

Working Principle:

As the impeller rotates, pulp from around the bottom of the tank is sucked into the blades of the impeller from the lower end of the impeller.

At the same time, the low-pressure air fed by the blower enters the hollow shaft and the air distributor of the impeller cavity. After the pulp and the air are fully mixed between the blades, they are pushed out obliquely upward from the periphery of the upper half of the impeller and enter the entire tank after being stabilized and oriented by the stator. The bubbles rise to the foam stabilization zone, and after the enrichment process, the foam overflows from the overflow weir and enters the foam tank. Another part of the pulp flows to the lower part of the impeller and is stirred by the impeller to form mineralized bubbles again. The remaining pulp flows to the next tank until it becomes tailings. Flowing to the lower portion of the impeller, another part of the pulp is stirred into mineralized bubbles once again. The remaining pulp flows to the next tank and becomes tailings.

- Flotation is almost independent of mineral density in terms of the ups and downs of minerals. Chalcopyrite and quartz, for example, have densities of 4.2 for the former and 2.68 for the latter. Although chalcopyrite is a heavy mineral, it floats easily, as opposed to quartz, which sinks. The floatability of minerals is correlated with the affinity of water multi-tank flotation machines. Floating minerals that have a high affinity for water and are easily wetted by water make it difficult to adhere to the bubbles. Minerals that have little affinity for water and are not easily wetted by water tend to float.

| Model | Volume of Tank(m³) | Rotating Speed of Rotor(r/min) | Wind Pressure(Mpa) | Handing Capacity(m³/min) | Motor Power(kw) | Inner Dimension(mm) | Weight of Single Tank(kg) |

| BS-K2.8 | 2.8 | 248 | 0.015 | 0.4-3 | Y160M2-8.5/5.5 | 1550*1550*1350 | 1740 |

| BS-K4 | 4.0 | 210 | 0.5-4 | Y160L-8/7.5 | 1850*1850*1550 | 2568 | |

| BS-K8 | 8.0 | 180 | 1.0-8.0 | Y180L-6/15 | 2350*2350*1950 | 4460 | |

| BS-K16 | 16.0 | 160 | 2.0-15.0 | Y250M-8/30 | 2800*2800*2400 | 9231 | |

| BS-K24 | 24.0 | 154 | 7-20 | Y280S-8/37 | 3200*3200*2800 | 11107 |

Advantages of the BS-K Inflatable Flotation Device

The BS-K inflatable flotation device is distinguished by its well-engineered structure and exceptional performance. Featuring a U-shaped groove body, the device minimizes tailings deposition. Equipped with a main shaft on the frame, it offers ease of installation and a lightweight design. A small impeller diameter and low peripheral speed contribute to reduced energy consumption.

Key benefits include:

- High flotation index

- Minimal wear on components

- Significant energy savings (30-50%)

- Efficient air and bubble dispersion

- Stable foam formation

- Complete suspension of solid particles

- Optimal slurry-gas mixing

Instructions for Flotation Cell Use

When ordering the BS-K inflatable flotation device, please specify the desired model quantity and provide the following details:

- Configuration scheme and feeding method

- Number and transmission mode of scraper drive (right or left)

- Quantity of ore feeding box, middle box, and raw ore box

Please note that the device does not come with a factory-installed motor starting device. The gate is custom-made according to manufacturer specifications, with large-scale flotation machines employing motor gates.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]