Description

Name: Hammer Crusher, Hammer mill crusher, hammer rock crusher, hammer mill grinder

Motor power: 7.5-500kw

Feed particle size: ≤1800mm

Production capacity: 5-280t/h

Uses: All types of ores with a compressive strength of less than 100 mpa and less than 15% moisture content.

Structure: hammer mill crusher is composed of a box body, rotor, hammerhead, counterattack lining plate, sieve plate, and so on.

Hammer crushers reduce materials through impact force. Constructed with a box-shaped body, rotor, hammerheads, impact liners, and a sieve plate, these machines can adjust the output particle size by modifying the gap between the grate and discharge opening to suit various applications. They excel at crushing medium-hard, brittle materials like cement, gypsum, salt, coal, brick, and limestone across industries such as chemicals, power generation, and metallurgy.

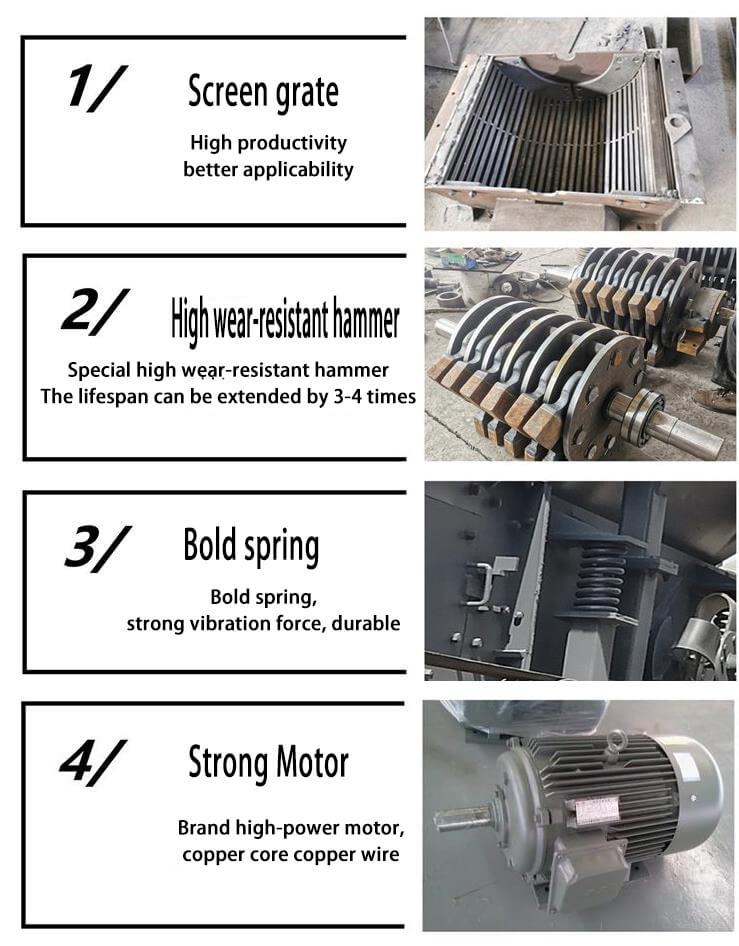

Key Advantages:

- Efficient Crushing: Hammer crushers combine feeding and crushing in a single unit, reducing costs by up to 35% compared to two-stage crushing processes.

- Durable Design: Optimized design significantly extends hammerhead lifespan by reducing wear by 4-6 times.

- Versatility: Capable of processing both wet and dry materials from diverse industries, including highways, railways, tunnels, and cement production.

Working Principle:

Hammer mills consist primarily of a rotor equipped with hammerheads. During operation, the motor propels the rotor to high speeds within the crushing chamber. Material is fed into the chamber from the upper inlet where it undergoes impact, shearing, and tearing by the rapidly rotating hammerheads. A sieve plate is installed at the lower part of the rotor. Particles smaller than the sieve openings pass through, while larger particles are retained for further reduction until they meet the desired size and can exit through the sieve. The enclosed design effectively prevents dust pollution within the crushing environment and eliminates ash leakage.

Features:

- High efficiency and sustainability: Delivers exceptional crushing performance while minimizing energy consumption and environmental impact.

- Versatile material handling: Effectively crushes materials with varying moisture content without clogging or sticking.

- Optimized particle size distribution: Unique design prevents over-crushing by evenly distributing material and precisely screening particles.

- Integrated crushing stages: Combines coarse and fine crushing processes, eliminating the need for additional equipment.

- Low operational impact: Operates quietly with minimal vibration, dust, and power consumption.

- Adjustable output: Allows for precise control of product particle size.

- Ease of maintenance: Simple machine design facilitates maintenance and requires minimal space.

- Advanced protection: Equipped with a hydraulic automatic retreat device and debris removal system to safeguard against damage from foreign objects.

| Model | Rotor speed (r/min) | Input opening size(mm) | Max. feed size (mm) | Discharged Size (mm) | Capacity (t/h) | Power(kW) | weight (t) | Overall Dimension (L×W×H) (mm) |

| DME400×400 | 1500 | 145×450 | 100 | 0-30 | 5-8 | 7.5 | 0.9 | 844×942×878 |

| DME600×400 | 1000 | 295×450 | 100 | 0-35 | 10-12 | 18.5 | 1.03 | 1054×972×1117 |

| DME600×600 | 1000 | 295×570 | 100 | 0-35 | 12-18 | 45 | 2.14 | 1315×840×1501 |

| DME800×600 | 1000 | 350×570 | 120 | 0-45 | 20-25 | 55 | 2.45 | 1515×2586×1040 |

| DME800×800 | 1000 | 350×850 | 120 | 0-45 | 35-45 | 55 | 3.05 | 1515×2831×1040 |

| DME1000×800 | 1000 | 580×850 | 200 | 0-45 | 25-40 | 110 | 6.5 | 3206×2210×1515 |

| DME1000×100 | 1000 | 580×1060 | 200 | 0-45 | 40-80 | 132 | 7.6 | 3514×2230×1500 |

| DME1250×800 | 750 | 650×850 | 200 | 0-45 | 20-50 | 132 | 11.7 | 2630×1780×2050 |

| DME1250×125 | 750 | 650×1330 | 200 | 0-45 | 90-110 | 185 | 13.2 | 2630×2180×2050 |

| DME1400×140 | 750 | 1050×154 | 250 | 0-45 | 120-170 | 280 | 17.2 | 2790×2800×2310 |

| DME1600×160 | 600 | 1500×178 | 350 | 0-60 | 220-280 | 450 | 22.8 | 3350×3120×2640 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]