Description

The High-Intensity Roller Type Dry Magnetic Separator adopts a self-developed permanent magnetic drum separator, featuring high intensity and high gradient. It has been successfully applied in the industrial minerals sector. It is equipped with high-energy rare earth neodymium permanent magnetic roller components, manufactured and assembled under strict quality control, generating a magnetic field gradient capable of efficiently removing weakly magnetic contaminants.

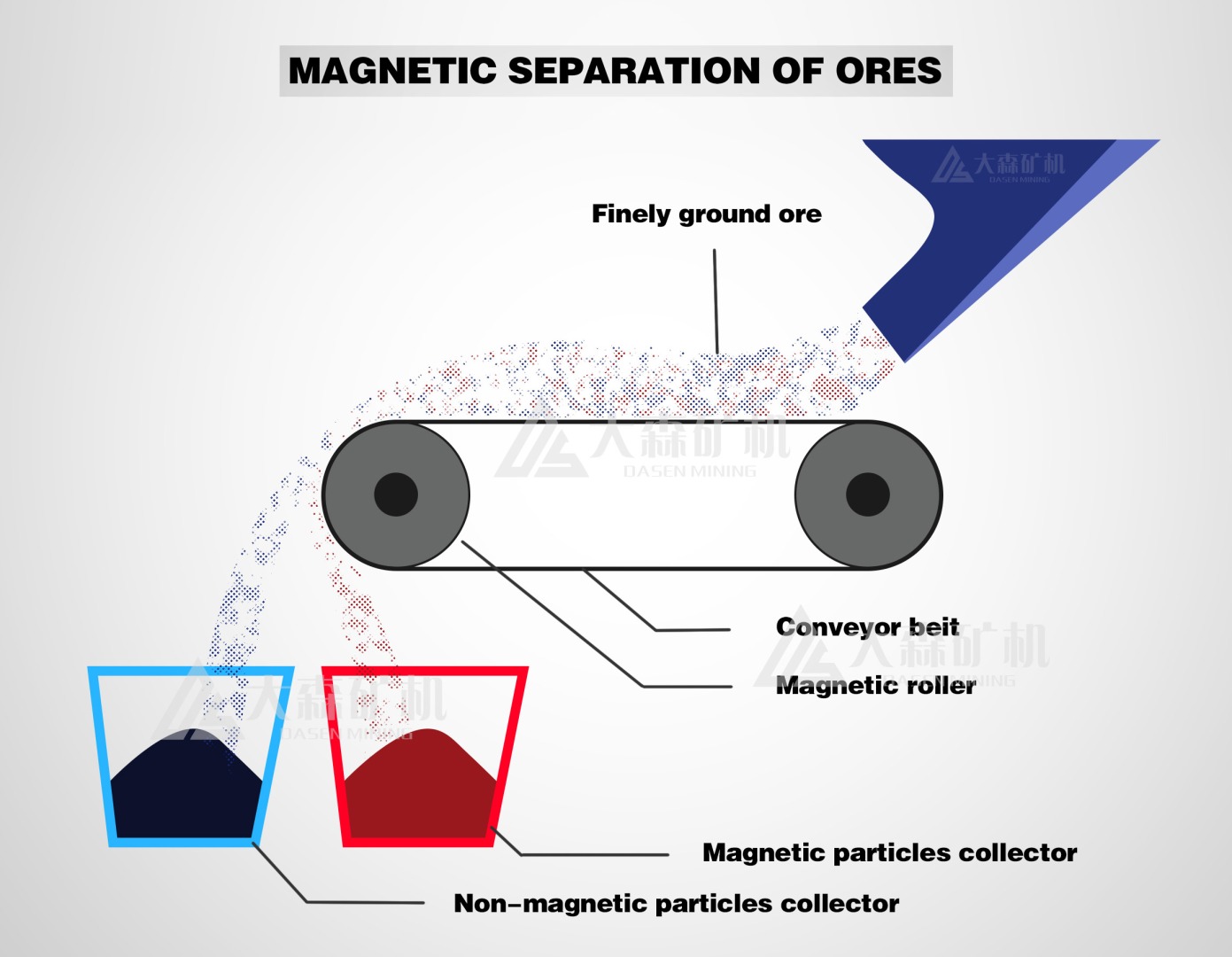

Working Principle:

Materials are conveyed to the magnetic drum area via a conveyor belt, where magnetic particles are adsorbed on the surface of the drum, while non-magnetic particles fall freely. The magnetic particles are removed as the drum rotates to a weaker magnetic field area, completing the magnetic separation process.

Features:

- Optional magnetic drum diameters: 65mm, 75mm, and 100mm

- Conveyor belt width up to 1200mm

- 0.5 HP variable speed DC/AC gear motor drive, adjustable within the range of 0 to 100 RPM

- Vibratory feeder with control device

- Wear-resistant circular conveyor belt with a thickness of 0.35mm

- Multiple-stage system available, up to 6 stages

- Offered in different magnetic strengths: 8,000 Gauss, 10,000 to 11,000 Gauss

Magnetic Separator Case:

We are shipping a full container of the High-Intensity Roller Type Magnetic Separator/Three-disc electromagnetic separator to Nigeria.

Since Nigeria produces tin and tantalum ore, this machine is viral there.

Permanent Magnetic Separator Application Range:

The dry-type ilmenite permanent magnetic separator is suitable for sorting and purifying a range of minerals including titanium ore, chromite, garnet, quartz, feldspar, manganese ore, rare earth ore, niobium tantalum ore, limonite, zircon, monazite, rutile, garnet, andalusite, and other excellent magnetic difference minerals.

Services:

DasenMining Company offers comprehensive technical services, including factory engineering design, mine site construction design, on-site assembly, installation, commissioning, and training.

Testing:

The company’s factory is equipped with testing facilities for client samples (approximately 5-10 kilograms), free of charge, for demonstration of machine performance.

| Model | Magnetic field strength(GS) | Feed particle size(mm) | processing power(T/h) | Feeder power(KW) | monitor power(KW) |

| CTG160*800 | 12000-16000 | <5 | 4-6 | 0.2 | 1.1*2 |

| CTG160*1200 | 12000-16000 | <5 | 6-8 | 0.4 | 1.5*2 |

| CTG160*1500 | 12000-16000 | <5 | 8-10 | 0.4 | 2.2*2 |

In conclusion, the dry-type ilmenite permanent magnetic separator is a reliable and efficient equipment for sorting various minerals. With its stable performance, adjustable processing capacity, and wide applicability, it is widely used in the mining industry.

We can provide you with more information about Dry magnetic separation. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]