Description

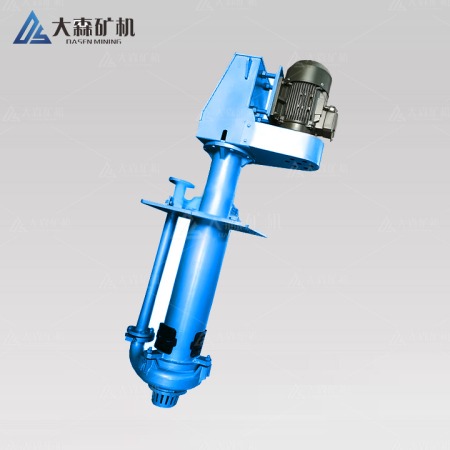

Name: carbon extraction pump, carry carbon pump, carbon lifting pump, carbon pump

Lifting height: 3-5M

Product features: no running parts

Carry Carbon Pump

A carry carbon pump is a pneumatic device that utilizes compressed air as a power source to transport materials.

Working Principle: High-pressure air is introduced into the air lifter through a central charging pipe. This injection reduces the density of the pulp within the pipe, creating a pressure differential between the pulp inside the pipe and the pulp in the tank. The resulting pressure difference forces the pulp from the tank upward through the air lifter to an elevated location.

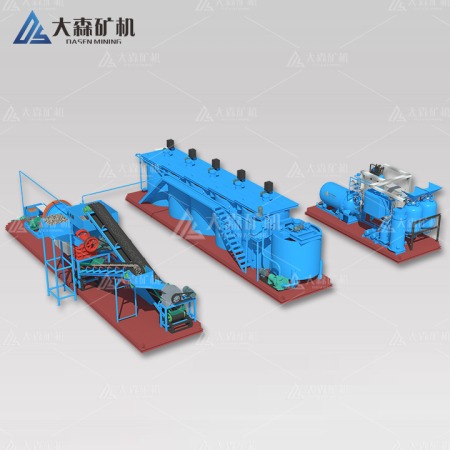

Advantages and Characteristics of Air Lifter Carbon Slurry Process

The air lifter system employed in carbon slurry processing offers several key advantages. Its scientifically designed mechanism significantly reduces carbon damage. With high efficiency, the system can thoroughly mix carbon within approximately 30 minutes per cycle. Furthermore, the air lifter is easily integrated into existing leaching or adsorption tanks, simplifying operation and maintenance.

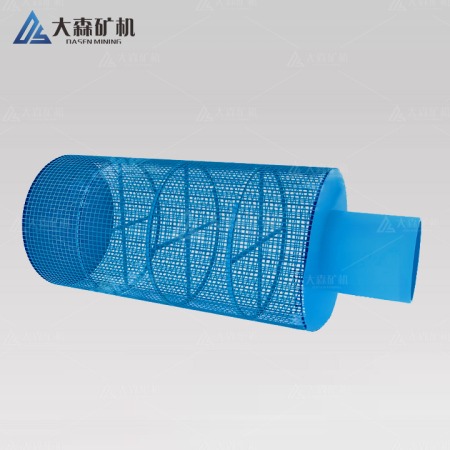

Air Lifter Application in Carbon Slurry Process

The air lifter plays a crucial role in the carbon slurry process. Cyanide slurry is introduced into the initial leaching tank and progresses through subsequent tanks, ultimately exiting the final adsorption tank as cyanide tailings following safety screening. Simultaneously, regenerated or fresh carbon is added to the last tank and is systematically transferred from tank to tank by the air lifter. The carbon-laden slurry undergoes sieving and washing to produce gold-loaded carbon, which is subsequently processed through electrolytic deposition.

| Model | Head

(m) |

Flow rate(r/min) | Rotating speed of main

shaft |

Diameter

Of discharging pipe |

Model | Power(kw) | Weight | Remarks |

| KQT-3 | 3 | 1.6 | 516 | 50 | Y100L1-4 | 2.2 | 630 | 50Ⅰ |

| KQ7-7 | 7 | 1.6 | 817 | 50 | Y112M-4 | 4 | 640 | 50Ⅱ |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]