Description

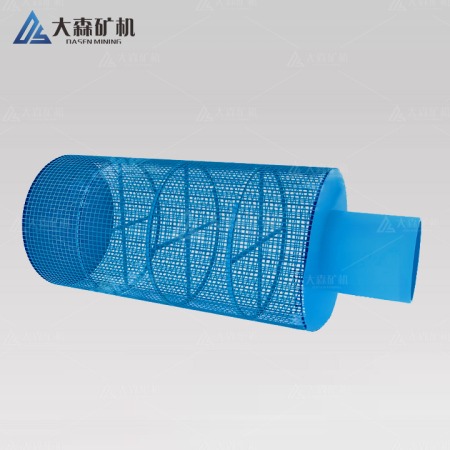

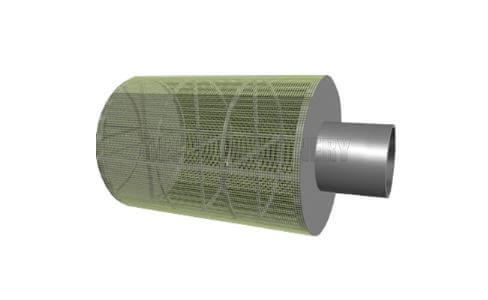

Name: carbon separator, carbon separation screen

Features: This product is installed in the carbon leaching tank, the function is to separate the pulp and activated carbon

Selection instructions: Additionally, when ordering a screen, it is necessary to specify the model and quantity, as well as the type and material. There are no special instructions for processing and manufacturing according to the drawings provided by the manufacturer.

Sieve diameter: 300mm

Screen frame length: 1000mm

Screen size: 28 mesh, 20 mesh

Weight: 20kg, 35kg

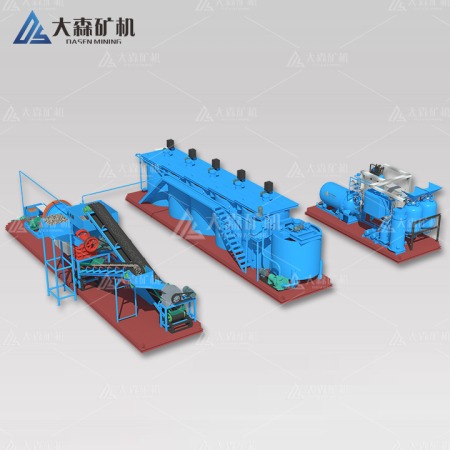

The carbon-in-pulp (CIP) method, employing a carbon separation screen, is a highly efficient technique for extracting alloyed gold from oxidation ores with significant mud content. By offering both high gold recovery rates and a fast return on investment, the CIP process has become a preferred choice in the gold mining industry.

Application of Activated Carbon Separation

Activated carbon separation is a critical process employed in the leaching tanks of Cyanide Carbon Pulp Plants. This process leverages carbon screens to effectively separate activated carbon from the pulp. The separated pulp is then directed to subsequent leaching tanks, while the activated carbon remains within the original tank.

Carbon screens offer several advantages for this application. Their structure is simple, making operation and maintenance convenient. Additionally, they are resistant to clogging, have a long service life, and are cost-effective.

By utilizing carbon screens, Cyanide Carbon Pulp Plants optimize their leaching process, ensuring efficient activated carbon recovery and smooth pulp transfer.

Carbon Screen Advantages

Carbon screens offer several advantages in cyanidation carbon pulp plants:

- Simple design: The structure is straightforward.

- Easy operation and maintenance: Requiring minimal effort.

- Low cost: Economical to implement and operate.

- Long service life: Durable and reliable.

The screen effectively separates activated carbon from the pulp, allowing the pulp to flow freely to subsequent leaching tanks while retaining the carbon.

Carbon Separator: Advantages and Challenges

Advantages:

- Simple design: Easy to construct and maintain.

- Low cost: Economical to operate.

- Long lifespan: Durable and requires minimal replacement.

- Effective separation: Reliably separates activated carbon from pulp in cyanidation processes. The separated pulp can flow freely to subsequent leaching tanks, while the activated carbon is retained for further processing.

Challenges and Solutions:

Carbon separators can experience clogging issues due to factors such as excessive pulp quality, high viscosity, elevated bottom carbon density, or the presence of impurities like sawdust. Clogging leads to operational inefficiencies, including screen damage and metal loss.

To address these challenges, consider the following solutions:

- Enhanced sawdust removal: Implement more effective methods to eliminate sawdust from the pulp.

- Pulp and carbon density adjustment: Reduce pulp mass fraction or bottom carbon density as necessary.

- Optimized air supply: Increase low-pressure air volume to improve carbon deposit removal from the screen.

By implementing these strategies, the performance and longevity of the carbon separator can be significantly enhanced.

| Model | Sieve

Diameter(mm) |

Screen frame length(mm) | Screen size(mm) | Weight(kg) |

| SG300 | Φ300 | 1000 | 28 | 20 |

| SG500 | Φ500 | 1000 | 20 | 35 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]