Description

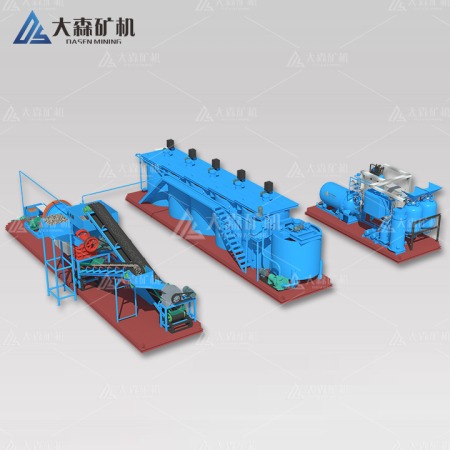

- The 10TPD Small Scale Mobile Gold Leaching Plant represents a revolutionary advancement in the field of gold beneficiation. We designed this portable plant to conduct both professional and non-professional tests directly at the mining site, ensuring a seamless transition from exploration to production. Integrating the entire process from ore testing to final industrial trials, offers a cost-effective solution for understanding ore properties, optimizing recovery rates, and minimizing investment risks. With its ability to be operational within three days of arrival and its high recovery rate of over 90%, this plant is the ideal choice for efficient and profitable gold mining operations.

In the ‘standard operation’ of mine development, the following processes are essential:

- Processability test: We will use a small amount of material to conduct an exploratory beneficiation test and evaluate the industrial utilization value of ore veins.

- Mineral processing test: To collect ore samples within 100 kg, conduct mineral processing tests in the laboratory, and estimate economic indicators.

- Semi industrial tests in the mining area, we collect dozens of tons of minerals and conduct tests to obtain data based on the ‘production operation status’ as the preliminary preparation for constructing the beneficiation plant.

- Industrial test: For large-scale mines, the industrial test is a full process test in the “production” state, which serves as the basis for mine design, plant construction, and production operations.

DasenMining Mobile Gold Leaching Plant Case:

The cost of standardizing the beneficiation process is enormous and the time cycle is long. However, the 10TPD Mobile Gold Leaching Plant can effectively save costs and shorten the beneficiation cycle.

The “10TPD Small Scale Mobil Gold Leaching Plant” is a kind of mobility, which can complete all professional & non-professional tests in the mining area, and is also a beneficiation plant in production status. The Portable Gold CIL/CIP beneficiation plant perfectly avoids all test risks in the early stage of development at the lowest cost. It is best to understand the ore at the lowest cost, clarify the economic benefit, and reduce the risk of mine development.

Advantages of the Gold 10TPD CIL/CIP Processing Plant:

- Ore Suitability and Process Overview

The 10TPD CIL/CIP processing plant is optimized for oxidized quartz vein gold ore, characterized by its relatively simple mineral composition. Granular gold is recovered through gravity separation using mercury, while the remaining lower-grade gold is processed via cyanidation.

- Plant Design and Mobility

The Mobile Gold Leaching Plant undergoes rigorous factory testing before shipment, ensuring seamless on-site operation. Its compact design facilitates easy relocation between mining sites, minimizing setup costs and time. In most cases, the plant can be operational within three days of delivery.

- Environmental Impact and Efficiency

The CIP/CIL process incorporates a closed-loop system to recycle water and minimize environmental impact. By eliminating the discharge of barren liquid and cyanide-containing wastewater, we adhere to strict environmental regulations. Additionally, the plant’s high efficiency is demonstrated by gold recovery rates exceeding 97% and cyanide recovery rates reaching 90%.

- Testing and Data Analysis

To guarantee accurate results, we implement rigorous testing protocols. Multiple sampling and analysis are conducted to ensure data reliability. The 10TPD CIL/CIP processing plant offers a comprehensive solution, from initial ore testing to full-scale production. This enables mine owners to make informed decisions based on thorough data analysis.

- Economic Benefits

The plant’s rapid setup and production commencement contribute to accelerated return on investment. Within a month of operation, the equipment investment can typically be recovered. Moreover, the ability to conduct on-site testing and production optimizes resource utilization and minimizes operational costs.

- Flexibility and Adaptability

The mobile nature of the plant allows for flexible deployment to various mining locations. This adaptability, combined with efficient production capabilities, makes it a valuable asset for mining operations of different scales.

We strongly recommend using our 10TPD Small Portable Gold Process Plant before building a gold ore cyanidation facility. Contact us for inquiries.

Whatsapp:+86 133 1927 7356

Email:[email protected]