How On-Site Concentration Measurement Optimizes Mineral Processing

In the realm of mineral processing, optimizing operational efficiency and ensuring product quality hinges on accurate and timely concentration measurements. This article delves into the significance of real-time concentration measurements during the ore beneficiation process, focusing on the “on-site concentration measurement method” that incorporates density and fineness determinations.

Understanding Density and Fineness Measurements

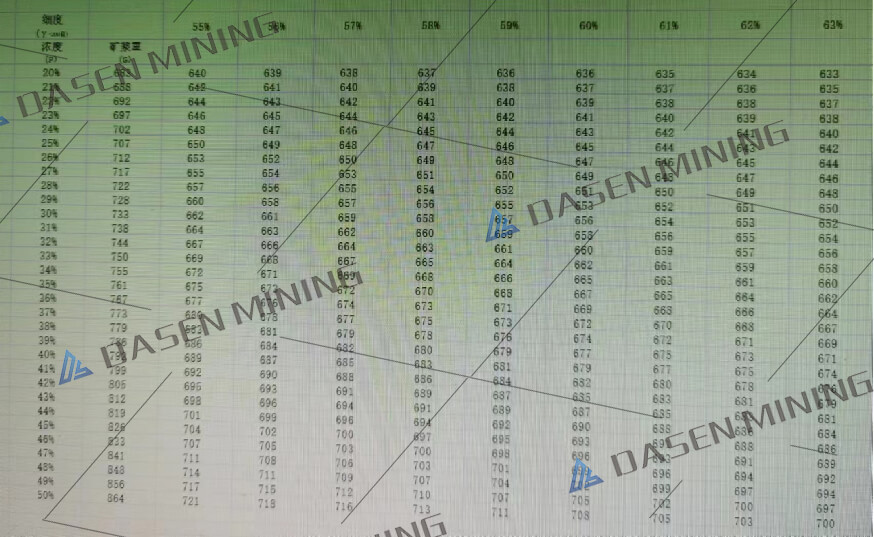

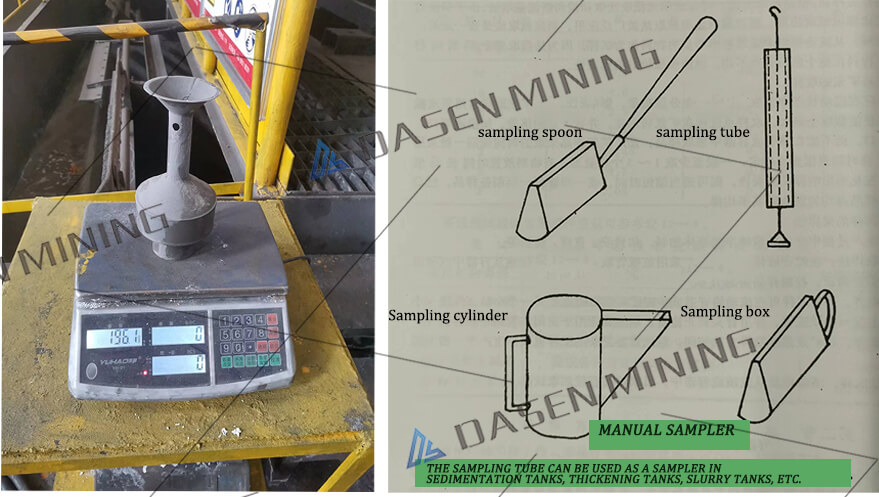

Density measurement quantifies the mineral concentration within the ore slurry. The on-site method involves extracting a slurry sample, transferring it to a density beaker, and weighing it against a reference table to determine concentration. Fineness measurement assesses particle size distribution by sieving the slurry and analyzing the remaining sand.

The Importance of On-Site Concentration Measurement

Process Optimization: Real-time concentration data empowers operators to make informed decisions for process adjustments and resource allocation, leading to enhanced extraction yields, reduced energy consumption, and minimized costs.

Quality Control: Continuous monitoring ensures consistent product quality, enabling timely identification and correction of any deviations.

Efficient Resource Utilization: Accurate concentration measurements facilitate precise resource allocation, preventing overconsumption and minimizing waste.

Safety Considerations: Monitoring potentially hazardous substances helps prevent accidents and maintain a safe working environment.

Significance of On-Site Concentration Measurement:

On-site concentration measurement, utilizing techniques like the “on-site concentration measurement method,” is indispensable for optimizing efficiency, ensuring product quality, and promoting safety in mineral processing. By embracing real-time monitoring, the industry can achieve greater profitability, environmental sustainability, and a safer working environment.

Whatsapp:+86 133 1927 7356

Email:[email protected]