New video:“Efficient Methods for Tungsten-Tin Ore Beneficiation”

The core topic is Tungsten Tin Ore Beneficiation and its various separation methods. The target audience is likely mining professionals, researchers, and students interested in mineral processing.

The first type is cassiterite (Tinstone) Ore

Cassiterite, also known as tinstone (SnO2), is a naturally occurring oxide of tin. It is colorless when pure but can appear brown or black due to iron impurities. This type of ore is often found in granite and pegmatites. The beneficiation process involves crushing and grinding, followed by gravity and magnetic separation due to the significant density differences between the minerals.

Today, most of the world’s cassiterite is mined in Malaysia, Indonesia, Bolivia, Nigeria, Myanmar, Thailand, and parts of China.

The second type is Alluvial Tin Ore:

Alluvial tin ore often contains related minerals such as wolframite, scheelite, and columbite. The beneficiation process typically involves washing and screening, followed by gravity and magnetic separation. This traditional method is favored due to its low operation cost, ease of operation, and high efficiency.

The third type Complex Sulfide Ores

Complex sulfide ores are usually found in underground deposits and require more complicated mineral processing, often involving froth flotation to produce a clean tin concentrate. Even then, the average Bolivian tin concentrate may only be 50 to 60 percent pure.

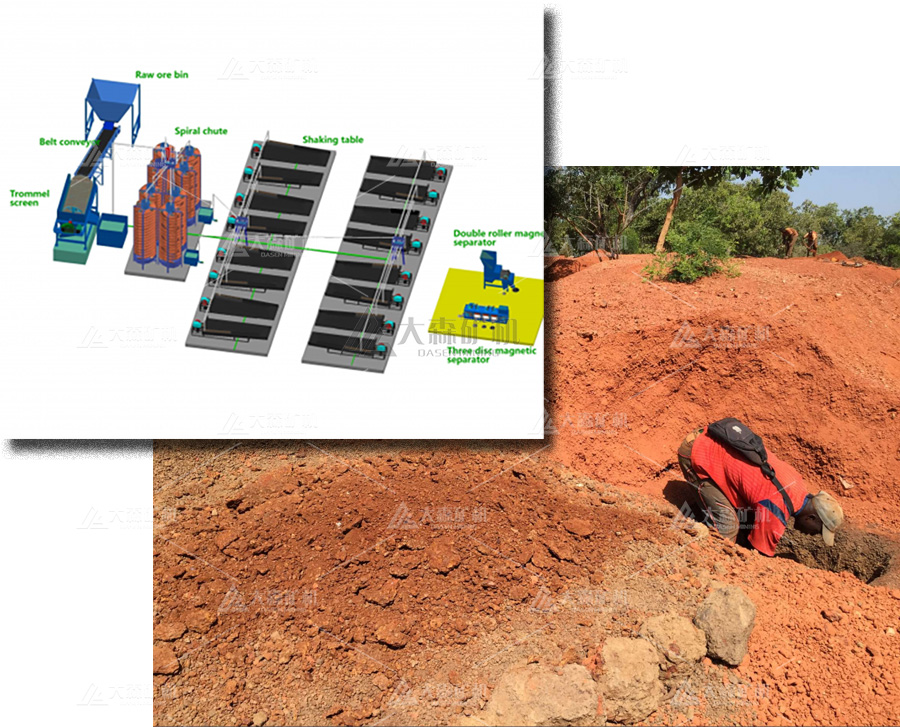

Beneficiation Equipment

Gravity Separation Machines:

- Spiral Chute

- Jig Machines

- Shaking Table

Magnetic Separation Equipment:

- Double Roller Magnetic Separator

- Three Disc Electromagnetic Separator

The three-disc electromagnetic separator is particularly effective for tin and wolframite ore separation and purification, with adjustable magnetic induction intensity ranging from 8000 to 28000 gauss. This allows for the one-time separation of various minerals, making the operation easy and efficient.

By understanding the different types of tungsten-tin ores and their respective beneficiation methods, we can optimize the extraction process, ensuring higher efficiency and better quality of the final product.

Currently it is the most commonly and widely used in tin ore and wolframite ore separation industry.

We can provide you with more information about the Tungsten tin ore beneficiation. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]