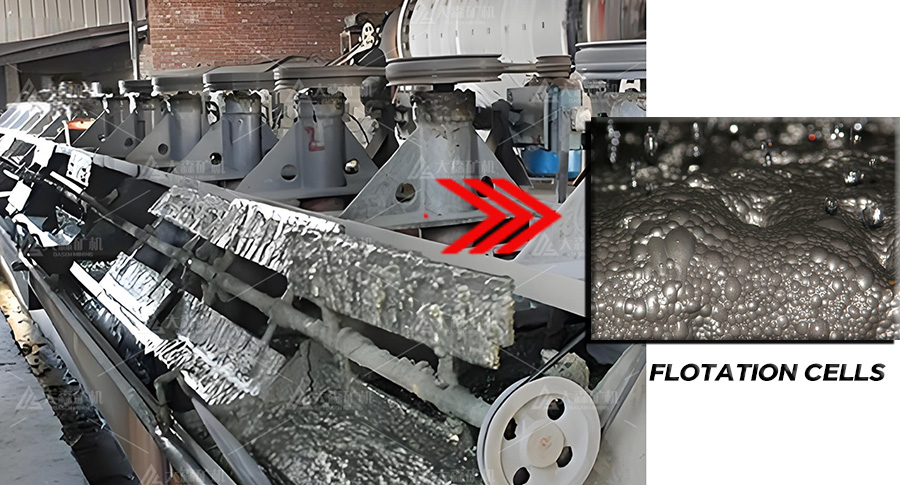

ldentifying and Judging the Flotation Process

Experience an in-depth exploration of froth characterization in mineral flotation and essential insights into the elutriation process for effective mineral separation.

- Observe the bubble

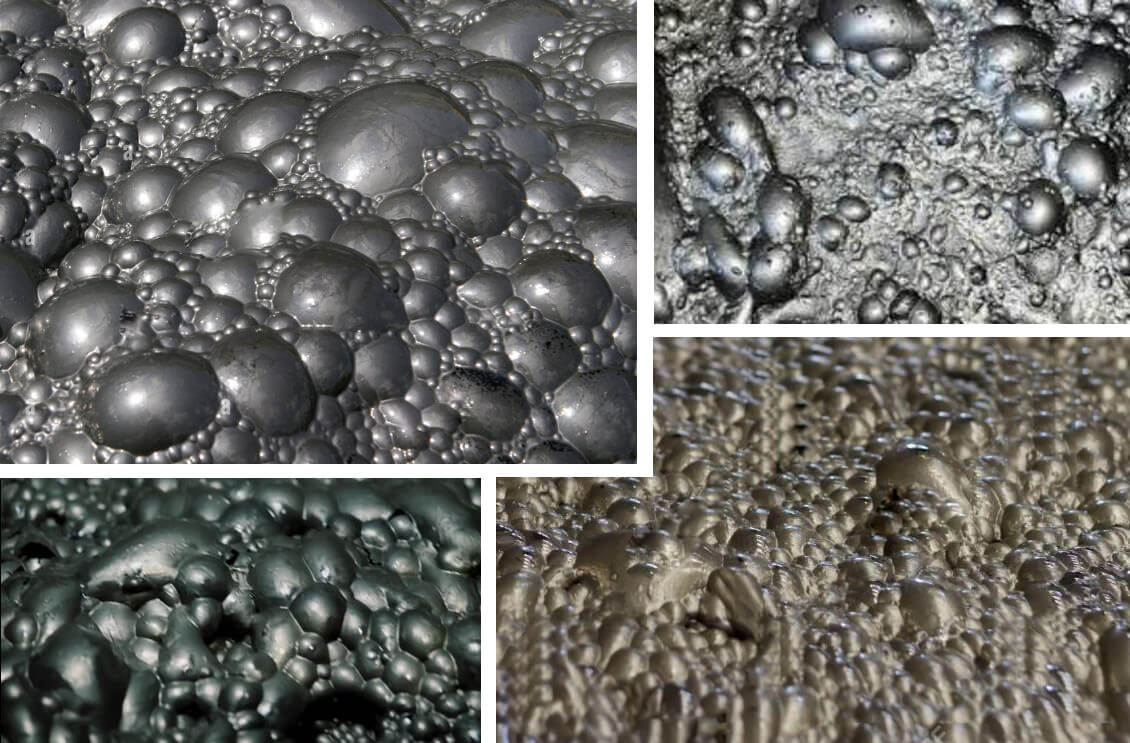

① False and real: reflect the mineralization degree of the bubble surface, that is, the number of mineral particles attached to the bubble surface. Real, which means firm, refers to the many dense mineral particles attached to the bubble surface. Ore particles attached to bubble surfaces are few and thin, which is called “virtual”, which means “empty”.

②Large and small: In a plate of sulfide ore flotation, bubbles with a diameter of 8 to 10 cm or more can be regarded as large bubbles; bubbles with a diameter of 3 to 5 cm can be regarded as medium bubbles; bubbles with a diameter of 1 to 2 cm can be regarded as Make vesicles.

③ Color: The color is determined by the color of the mineral grains attached to the bubbles’ surface and the water film’s color. Foam is the color of the lead in the flotation process of galena, raw lead in the flotation of pyrochlore, and tailings in the flotation of tailings. The darker the color of planktonic minerals in the selection area, the better the concentrate quality.

④ Gloss: The gloss of the foam is determined by the gloss of the attached minerals and the gloss of the water film. Rough selection of flotation sulfide minerals, the foam mineralization in the selection area is good, and its gold luster is strong. The mineralization of the foam in the sweeping area is poor, showing the vitreous luster of the water film.

⑤Outline: The froth stays on the surface of the pulp for a long time, and the mineral flow is strong. After the bubble wall is dry and incomplete, the bubble’s outline is blurred. The selected area of flotation is often this kind of froth. Many miscellaneous minerals are floating up, and the outline of the froth is blurred.

⑥Thickness and thinness: The thickness of the foam layer is mainly related to the amount of the foaming agent and the degree of mineralization of the bubbles. There are many foaming agents, the raw ore grade is high, the concentration is large, and the degree of mineralization is good. The foam layer is generally thicker. On the contrary, it is relatively thin.

⑦ Brittleness and stickiness: The brittleness of the foam is too high, the stability is poor, it is easy to break, and sometimes it cannot be scraped out. The viscosity of the foam is too high, the foam is too stable, and “running out” will occur.

⑧ Sound: When the foam is scraped into the foam tank by the scraper, it will make a “rustling” sound. Minerals with a large specific gravity and coarse particle size are often present in foams with this characteristic.

- Elutriationthe product

The essentials of elutriation are: according to the purpose of elutriation, select the appropriate elutriation location and the type of elutriation products, determine the appropriate amount of ore connection according to the mineral content to be inspected; determine the degree of elutriation according to the specific gravity and quantity of the inspected minerals.

Interested parties can contact us:Whatsapp:+86 133 1927 7356

Email:[email protected]