Innovative Processes to Improve Silver Ore Recovery

How to Find Native Silver

Native silver is primarily found in areas with volcanic activity and hydrothermal alteration. Here are some key areas to focus on:

- Circumpacific Belt: This region, including countries like Chile, Peru, and Mexico, is known for its rich silver deposits.

- Guya Metallogenic Belt: This belt, which spans South America, is another hotspot for silver exploration.

- Tethys Himalayan Metallogenic Belt: Countries in this belt, such as India and Pakistan, may also have potential silver deposits.

- Precambrian Greenstone Granite Terrane: This geological formation often contains silver-bearing minerals.

Specific signs to look for include:

- Low-temperature alteration zones: These areas, characterized by minerals like quartz and pyrite, often indicate the presence of silver.

- Arsenic, antimony, bismuth, mercury, sulfide, and sulfur salt mineral belts: These minerals are often associated with silver deposits.

- Iron manganese oxidation zones: These zones can also be indicative of silver mineralization.

- Copper, lead, zinc, tin, tungsten, and manganese ore areas: Silver is often found in association with these metals.

- Black rock series areas: These geological formations can contain silver-bearing minerals.

- Silver geochemical anomaly areas: Elevated levels of silver in soil or water samples can be a sign of a potential deposit.

Important considerations:

- Distinguish artificial silver anomalies: Be careful not to confuse naturally occurring silver anomalies with those caused by human activities like cloud seeding.

- Look for independent silver deposits: While silver is often found in association with other metals, it can also occur independently.

- Focus on areas with geological characteristics conducive to silver formation.

What are the Silver Recovery Technologies?

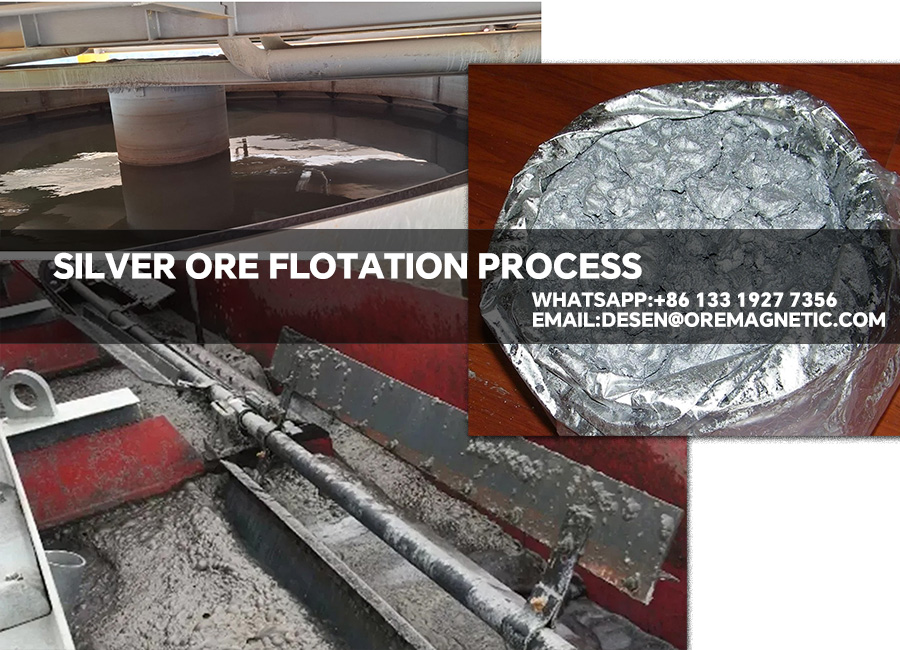

Silver Ore Flotation Process: A High-Efficiency Method for Silver Recovery

Silver ore flotation is a crucial process for separating silver and other valuable minerals from silver ore. This article will provide a detailed introduction to the silver ore flotation process, commonly used equipment, and the advantages and disadvantages of different methods.

Silver Ore Flotation Process

The silver ore flotation process generally includes the following steps:

- Crushing and grinding: The ore is crushed into fine particles for subsequent flotation operations.

- Flotation: By taking advantage of the differences in the surface properties of minerals, flotation reagents are added to separate silver minerals from gangue, thereby obtaining silver concentrate.

- Cyanidation: For high-grade silver ores, cyanidation can be used to further improve silver recovery. Cyanidation is a process in which silver is dissolved using reagents such as sodium cyanide, and then silver is recovered by displacement and other methods.

- Gravity separation: Gravity separation is suitable for processing coarser silver ores, taking advantage of the density difference between minerals.

Commonly Used Equipment for Silver Ore Flotation

Commonly used equipment for silver ore flotation includes flotation machines, ball mills, agitators, and concentrators. These devices together constitute a complete silver ore flotation production line.

Advantages and Disadvantages of Different Flotation Methods

- Flotation: Advantages: high recovery rate, wide range of applications. Disadvantages: high requirements for reagents, relatively high cost.

- Cyanidation: Advantages: high recovery rate, suitable for high-grade silver ores. Disadvantages: significant environmental pollution, complex operation.

- Gravity separation: Advantages: simple operation, low cost. Disadvantages: low recovery rate, only suitable for coarser silver ores.

Application of Silver Ore Flotation

Silver ore flotation is widely used in the development and utilization of silver mines, which is of great significance for improving silver recovery and reducing production costs.

If you have any questions about the above content or native silver ore concentrate and want to know more info, please contact the online service or submit your message.

Whatsapp:+86 133 1927 7356

Email:[email protected]