How to Choose the Right Magnetic Separator for Your Gold Ore

While magnetic separators are highly effective for certain minerals like zircon sand, monazite, and rutile, they are not suitable for processing gold, especially rock gold. This is because gold is not magnetic.

Common Methods for Gold Ore Processing

If you’re dealing with rock gold, the most common beneficiation methods include:

- Gravity separation: This method uses the difference in density between gold and other minerals to separate them.

- Flotation: This process involves creating a froth that selectively attaches to gold particles, allowing them to be separated from the rest of the ore.

- Cyanide: This chemical process is used to extract gold from ore by dissolving it in a cyanide solution.

Why You Might Be Considering a Dry Ore Processing Plant

Many customers inquire about dry ore processing plants due to:

- Bottlenecks in gold ore recovery rates

- Lengthy ore processing times

- High investment costs compared to returns

The Importance of Tailored Solutions

It’s essential to remember that each type of ore has unique properties, and the most effective mineral processing method will depend on these characteristics. Therefore, it’s crucial to choose a plan that is specifically tailored to your ore.

Two Types of Magnetic Separators

While magnetic separators aren’t ideal for gold, here are two common types:

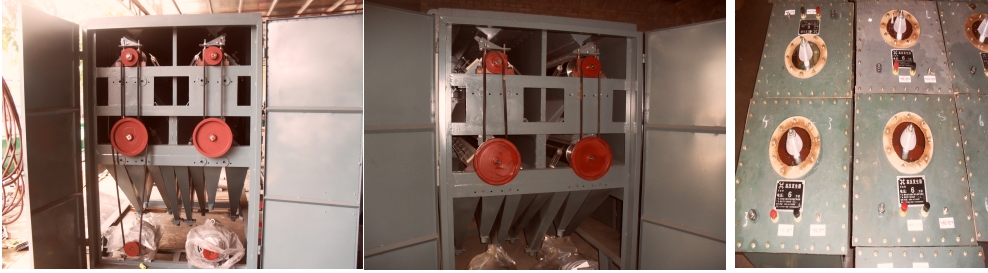

Double rollers magnetic separator:

Four rollers magnetic separator:

New Product :Three Roller Magnetic Separator

Conclusion

When considering gold ore processing, it’s important to understand the limitations of magnetic separators and choose a method that is appropriate for your specific ore type. By carefully evaluating your needs and consulting with experts, you can select the most effective solution for maximizing gold recovery and minimizing processing time.

If you have any questions, please feel free to consult us at any time.

Whatsapp:+86 133 1927 7356

Email:[email protected]