Gold Smelting Methods: Exploring Efficiency, Costs, and Reusability

In the gold mining industry, smelting is the final stage of extracting pure gold from ore. This process involves melting the gold-laden material to separate the precious metal from impurities. Here, we’ll delve into the two primary methods used to smelt gold-loaded carbon from cyanide leaching plants: desorption electrolysis and direct smelting.

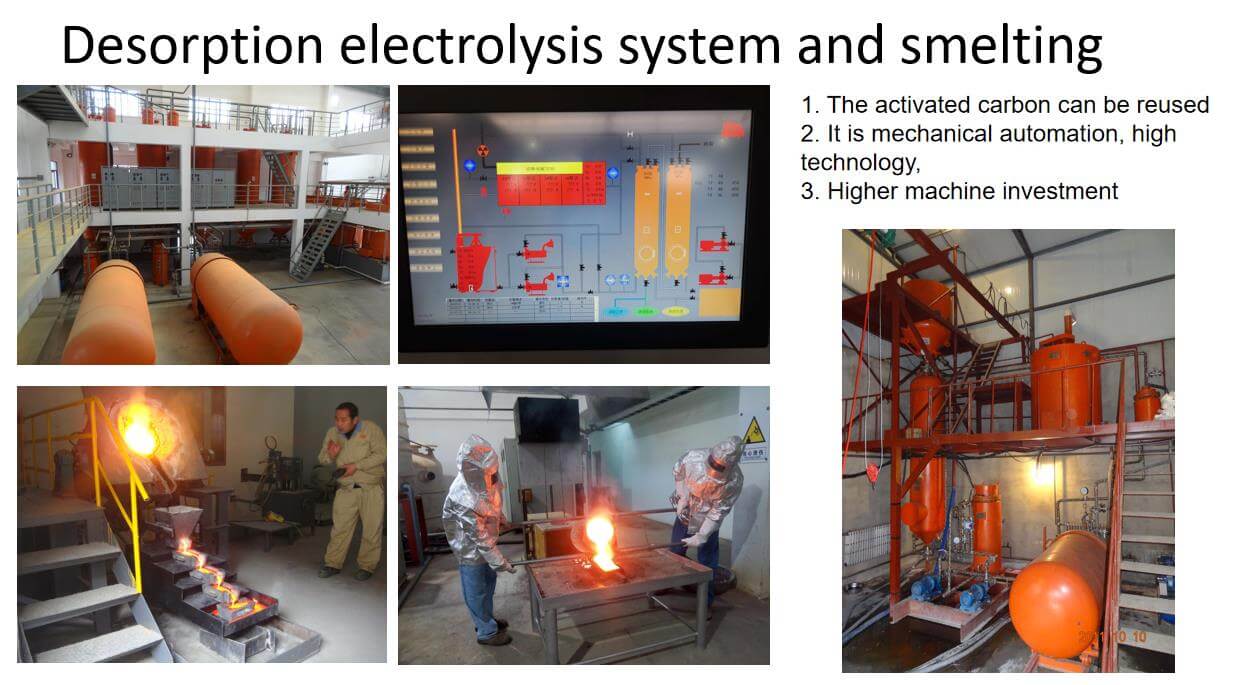

Desorption Electrolysis

- Process: Gold-loaded carbon is first subjected to desorption electrolysis, where gold is separated from the activated carbon. The gold mud is then smelted to produce gold ingots.

- Advantages:

- Activated carbon can be reused.

- Highly automated and technologically advanced.

- Disadvantages:

- Requires a higher initial investment in machinery.

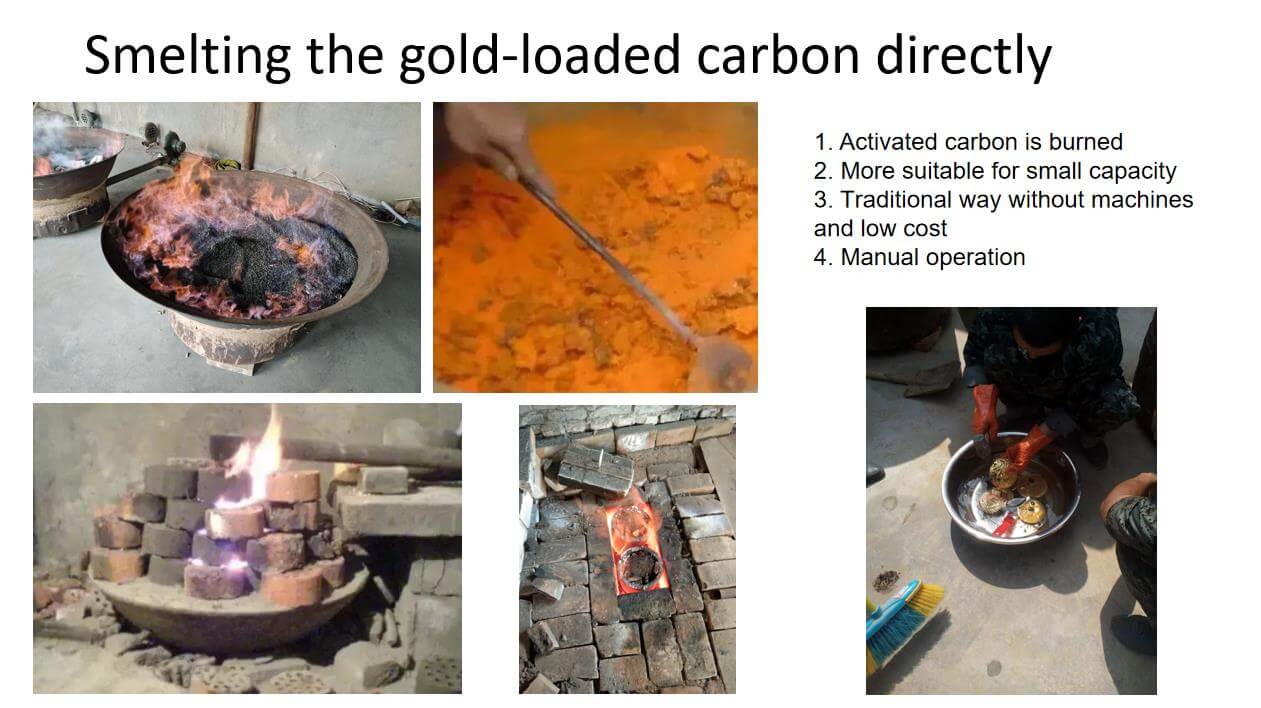

Direct Smelting

- Process: Gold-loaded carbon is directly smelted to produce gold ingots.

- Advantages:

- Suitable for small-scale operations.

- Traditional method with lower costs.

- Disadvantages:

- Activated carbon is burned, limiting reuse.

- Requires manual operation.

Conclusion

Both desorption electrolysis and direct smelting methods effectively produce gold ingots from gold-loaded carbon. The choice between the two depends on factors such as the scale of operation, budget, and desired level of automation.

Whatsapp:+86 133 1927 7356

Email:[email protected]