How to Optimize Copper Slag Flotation for Maximum Copper Recovery

Copper slag, a byproduct of copper production, represents a valuable resource for copper recovery. While its composition can vary, it often contains significant amounts of copper that can be extracted through the flotation process. This article explores the key factors influencing the efficiency of copper slag flotation, including particle size, pH, collectors and frothers, temperature, agitation, and froth collection system design.

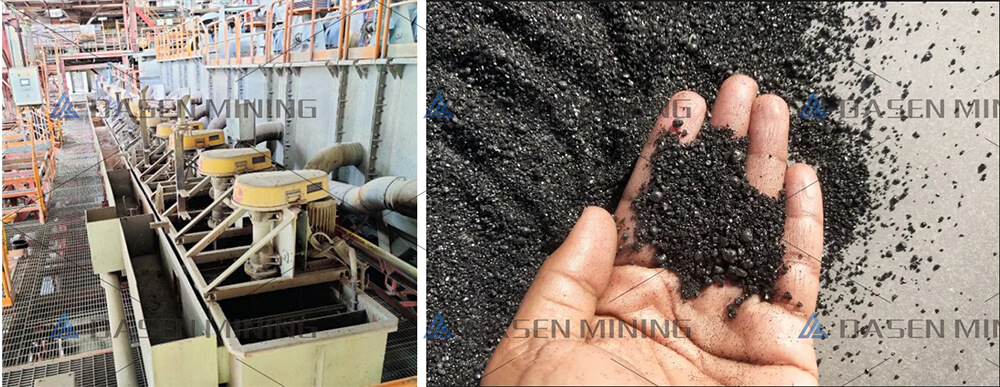

Flotation Process

Flotation involves separating minerals based on their surface properties. In the case of copper slag, the objective is to selectively attach copper particles to air bubbles and float them to the surface.

This is achieved by:

Hydrophobic Conditioning: Adding chemicals (collectors and frothers) to make copper particles water-repellent.

Bubble Attachment: The hydrophobic copper particles adhere to air bubbles.

Froth Formation: The copper-laden bubbles form a froth on the surface.

Froth Collection: The froth is skimmed off to recover the copper.

Optimization Factors

Particle Size: Smaller particles generally float more easily. Grinding the slag to a suitable particle size can improve flotation efficiency.

pH: The pH of the flotation pulp affects the surface properties of minerals. Adjusting the pH can optimize the selectivity of collectors and frothers.

Collectors and Frothers: The choice and dosage of collectors and frothers are crucial. Collectors make mineral surfaces hydrophobic, while frothers stabilize the froth.

Temperature: Temperature can influence the viscosity of the pulp and the surface properties of minerals. Optimal temperature ranges may vary depending on the specific slag composition.

Agitation: Proper agitation ensures uniform dispersion of particles, air bubbles, and reagents within the flotation cell. Excessive agitation can lead to froth breakdown.

Froth Collection System: The design of the froth collection system should minimize losses of copper to the tailings and maximize copper recovery.

Copper slag flotation offers a viable approach for recovering valuable copper from this industrial byproduct. By carefully considering factors such as particle size, pH, reagents, temperature, agitation, and froth collection, operators can optimize the process to achieve maximum copper recovery. Continuous research and development in flotation technology are also contributing to improved efficiency and sustainability in copper slag processing.

Whatsapp:+86 133 1927 7356

Email:[email protected]