How to Improve Lead-Zinc Ore Flotation Efficiency?

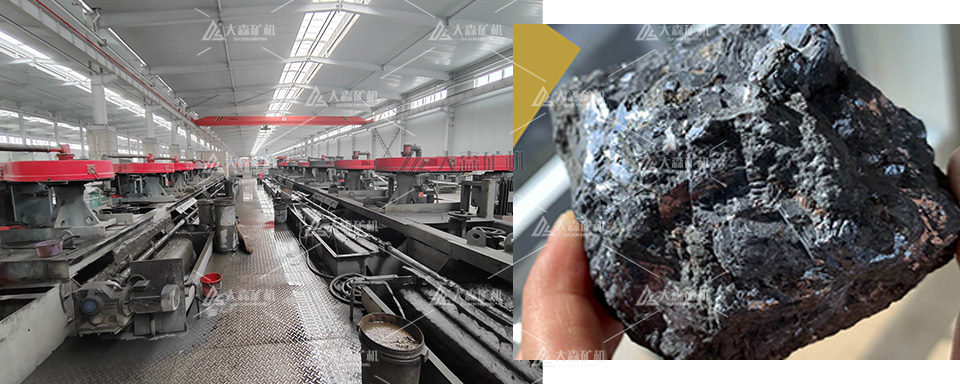

In the realm of the lead zinc flotation process, the beneficiation of lead-zinc sulfide ores presents unique challenges due to the presence of minerals like galena, sphalerite, pyrite, and chalcopyrite. The primary goal is to not only recover valuable minerals but also to selectively separate them into smeltable products. Over the years, the extraction of lead-zinc metals and associated precious metals from these ores has significantly contributed to industrial development. Despite advancements in lead-zinc separation techniques, some concentrators still face issues such as low separation efficiency, low concentrate recovery rates, and poor concentrate quality.

To tackle these problems, it’s crucial to understand and implement effective strategies in the lead zinc flotation process. The beneficiation of lead-zinc sulfide ore primarily relies on flotation. In most cases, zinc ore is more abundant than lead ore, leading to the adoption of the “suppression of zinc and floating lead” method. This approach involves several key principles:

1. Separation of Lead and Zinc: Due to the higher floatability of galena compared to sphalerite, the suppression of zinc while floating lead is a common practice. This can be achieved through various methods, including cyanide, low-cyanide, and non-cyanide processes. The cyanide method often employs a combination of cyanide and zinc sulfate.

2. Regulator Selection: Proper selection of regulators is critical for the separation process. The choice of regulators can significantly impact the efficiency and effectiveness of the flotation process.

3. Grinding Process: The grinding stage is another crucial aspect. Depending on the inlaid relationship of useful minerals like lead and zinc, a one-stage or multi-stage grinding process can be chosen. For lead-zinc sulfide ore, tailings regrinding or coarse concentrate regrinding is often employed, while medium ore regrinding is less common.

According to the inlaid relationship of useful minerals such as lead and zinc, the grinding stage can roughly choose a one-stage grinding process or a multi-stage grinding process. For lead-zinc sulfide ore, tailings regrinding or coarse concentrate regrinding is often used, and medium ore regrinding is rarely used.

1. Grinding particle size

2. Slurry temperature

3. Collecting agent

The above is an introduction to the flotation process of lead-zinc sulfide ore. In actual operation, if you want to choose a suitable, correct, and scientific lead-zinc ore beneficiation process, it is recommended to choose a beneficiation manufacturer with beneficiation qualifications to conduct a beneficiation test first. Fundamentally conduct a comprehensive ore analysis, and then formulate a beneficiation process that conforms to the actual situation.

If you have ideas or questions about lead-zinc ore flotation plant and industrial processing equipment, please contact us:

Whatsapp:+86 133 1927 7356

Email:[email protected]