Description

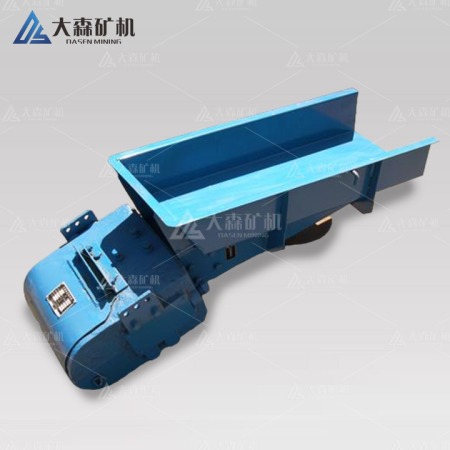

Name: Vibrating Feeder, vibrating screen feeder

Motor power: 3kW

Processing capacity: 80—800t/h

Application: Widely used in crushing and screening combined equipment in mineral processing, building materials, silicate, and chemical industries.

Structure: The vibrating feeder is composed of a feeding trough, a vibration exciter, a spring support, and a transmission device.

Vibrating feeders are high-performance inertial vibration machines designed to provide reliable material handling in mining and industrial applications. Powered by vibration motors, they ensure precise and continuous feeding of ores, minerals, and other bulk materials.

Advantages

- Offers an exceptionally long service life and maintains consistent vibration throughout its operational lifespan.

- Provides real-time adjustable excitation force for precise flow control.

- Features low power consumption and minimal noise levels, ensuring efficient and quiet operation.

- Its simple design allows for easy installation and operation.

Working Principle

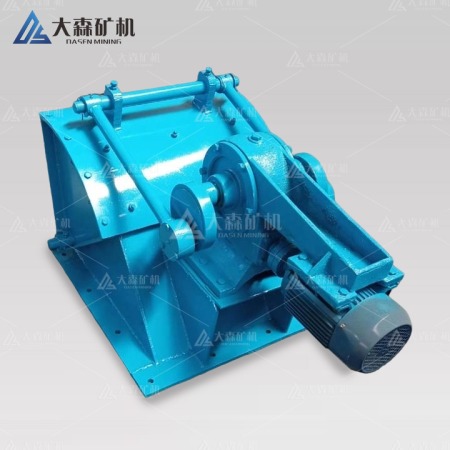

Vibration Exciters

Vibration exciters, comprising two counter-rotating eccentric shafts and gears, generate the vibrational force propelling the feeder body. This oscillatory motion ensures continuous material flow.

Vibration Motor

A vibration motor, equipped with eccentric blocks, drives the feeder table in a linear, periodic pattern. By inducing vertical acceleration surpassing gravity, the material is propelled forward in a parabolic trajectory. Continuous vibration maintains this forward motion, effectively conveying the ore.

Product Classification of Vibrating Screen Feeder:

Depending on the uniformity of ore breakage, block size, and fluidity, either a swing feeder or a wave feeder can be utilized. These feeders are particularly suitable for elliptical and directional vibration due to their tendency to be blocked by arching and the requirement for secondary crushing.

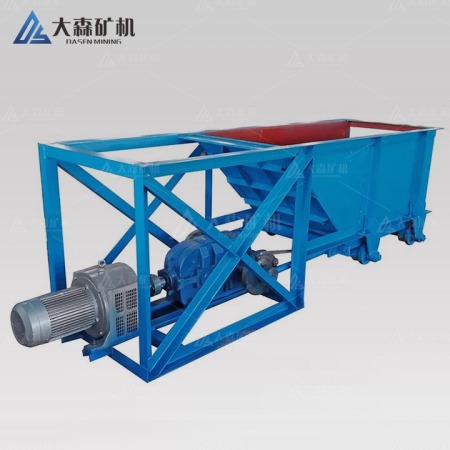

This equipment is a two-mass vibration feeder that operates using near-resonance inertial vibration of two masses. It features two or three rows of shearing rubber springs arranged vertically, with the lower pressure plate bolted to the balance body and the left and right side plates attached to the tank. The machine boasts a compact structure, balanced pressure, and stable start-up. It is unaffected by material load and blockages in the tank, and it is capable of handling feed granularity ranging from 0 to 850mm and large quantities from 8 to 1800 tons per hour. Additionally, it supports remote computer operation.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact: Whatsapp:+86 133 1927 7356

Email:[email protected]