Description

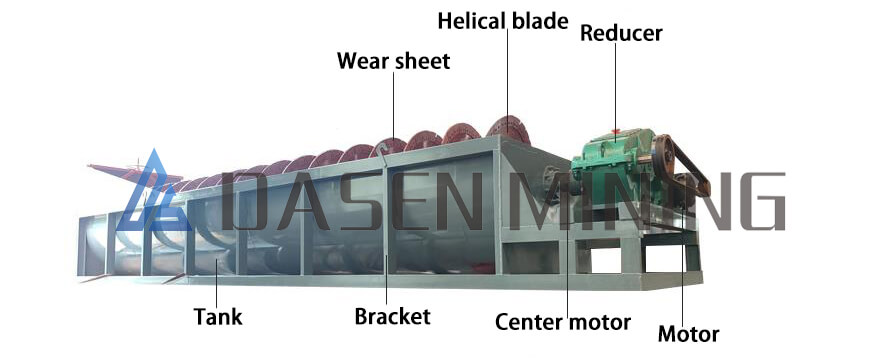

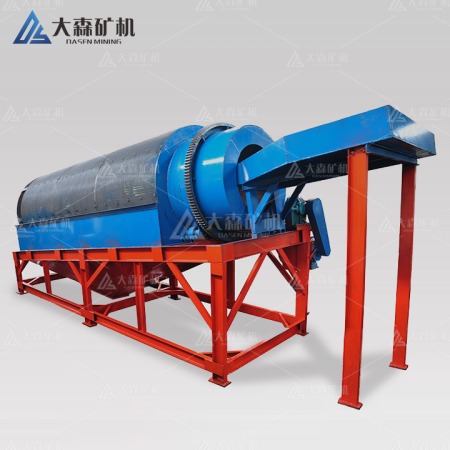

Name: Spiral Classifier

Processing capacity: 10~1785 t/d

Weight: 42188kg

Transmission motor power: 30kw

Scope of application: suitable for coarse particle classification

Structure: The transmission device is composed of a spiral body, a tank body, a lifting mechanism, a lower support (bearing bush), and a discharge valve.

Spiral classifiers are essential components in various mineral processing operations. They are widely used to classify ore sands and fine muds. In particular, they form a crucial part of closed-circuit grinding systems with ball mills. Additionally, spiral classifiers play a vital role in gravity and metal ore beneficiation processes for particle size classification. Beyond classification, these machines also contribute to desliming, dehydration, and cleaning processes. Renowned for their simplicity, reliability, and ease of operation, spiral classifiers are indispensable in the mineral processing industry.

Spiral classifiers are categorized based on the weir (overflow) location relative to the screw axis:

- Low Weir: This type has the overflow weir positioned lower than the screw’s rotation axis. Due to the limited settling area, it’s primarily used for dewatering coarse particles and washing sand ores with minimal mud content. It’s rarely employed in grinding applications.

- High Weir: The overflow weir sits higher than the rotating shaft but remains lower than the spiral’s top edge. This design offers a larger weir area with adjustable height within a specific range. This adjustability allows for controlling the settling area and, consequently, the classified particle size. High-weir spiral classifiers are commonly used in grinding processes.

- Submerged: This type features four submerged spiral blades at the overflow end, creating a deep classification pool. The minimal impact of the stirring action on the pulp surface translates to a stable grading zone. This design enables a large and fine overflow, making it ideal for classifying fine and secondary grinding products in concentrator operations.

Product Principle:

A spiral classifier operates on the principle that solid particles with different sizes and specific gravities settle at varying speeds in a liquid. Coarse particles sink to the tank bottom, while finer particles remain suspended and overflow. To facilitate mechanical grading, a screw mechanism propels the settled coarse material upwards for discharge. The classifier is integrated into milling circuits where it separates milled material into coarse and fine fractions. The coarse material is recycled to the mill via the screw feed inlet, while the fine material overflows for further processing. The classifier’s robust construction employs welded steel plates for the body and channel steel for the base. Wear-resistant pig iron sleeves protect the spiral shaft’s inlet and head. Both electric and manual lifting options are available.

Product Performance

Energy Efficiency: Consuming half the energy compared to traditional horizontal and vertical classifiers while maintaining identical processing capacity, this classifier offers superior energy efficiency.

Classification Efficiency: The classification efficiency is doubled compared to conventional horizontal and vertical classifiers, ensuring precise particle separation.

High Precision, Low-Speed Operation: The grading wheel rotates at a speed 50% lower than that of other classifiers for the same particle size, minimizing product contamination with oversize or undersize particles.

Durability: Engineered for longevity, the grading wheel exhibits exceptional wear resistance. For materials with a Mohs hardness below 5, the wheel experiences negligible wear. For materials with a Mohs hardness exceeding 7, the wheel lifespan is extended by 5 to 8 times compared to traditional classifiers.

Product Advantages

- Flexible Particle Size Control: The overflow particle size can be effortlessly adjusted between 25-90 mesh, offering unparalleled flexibility to meet diverse application requirements.

- Simplified Operation: The spiral classifier’s straightforward design combined with frequency conversion control ensures easy operation and minimal user intervention.

- Versatile Application: Ideal for both classification and desliming processes preceding beneficiation, this equipment excels in metal and gravity beneficiation applications.

- Low Maintenance and High ROI: The classifier’s simple structure translates to minimal maintenance needs, resulting in extended equipment life and a substantial return on investment.

| Model | Spiral diameter | Length of tank(mm) | Rotating speed(r/min) | Power(kw) | Dimension(mm)

(L*W*H) |

Weight(t) |

| FG-3 | 300 | 3000 | 12-30 | 1.1 | 3850*490*1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 1.1 | 5430*680*1480 | 1.6 |

| FG-7 | 700 | 5500 | 6-10 | 3 | 6270*980*1820 | 2.7 |

| FG-10 | 1000 | 6500 | 5-8 | 5.5 | 7590*1240*2380 | 4 |

| FG-12 | 1200 | 6500 | 4-6 | 7.5 | 8180*1570*3110 | 8.5 |

| FG-15 | 1500 | 8300 | 4-6 | 7.5 | 10410*1880*4080 | 12.5 |

| FG-20 | 2000 | 8400 | 3.6-3.5 | 11-15 | 10790*2530*4490 | 20.5 |

| FG-24 | 2400 | 9130 | 3.67 | 15 | 11650*2910*4970 | 25.7 |

| FG-30 | 3000 | 12500 | 3.2 | 20 | 16020*6640*6350 | 36.5 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]