Gold Ore Processing Equipment: A Guide to Setting Up Your Gold Mine

The gold mining process is a critical method for extracting this valuable metal, especially as gold continues to appreciate and its applications expand rapidly. Consequently, the intensity of gold mining is also increasing annually. The majority of gold raw materials in today’s market originate from vein gold mines, which account for approximately 75-85% of the total gold supply.

China hosts numerous vein gold deposits, including gold-bearing quartz veins, gold-bearing granite altered by pyrite, gold-bearing tungsten arsenic ore quartz veins, and gold-bearing polymetallic sulfide ore quartz veins. Each of these deposits requires a tailored gold mining process to maximize gold recovery.

So, what equipment is needed to open a gold ore concentrator? How much does a set of equipment cost?

Stages of Gold Ore Beneficiation

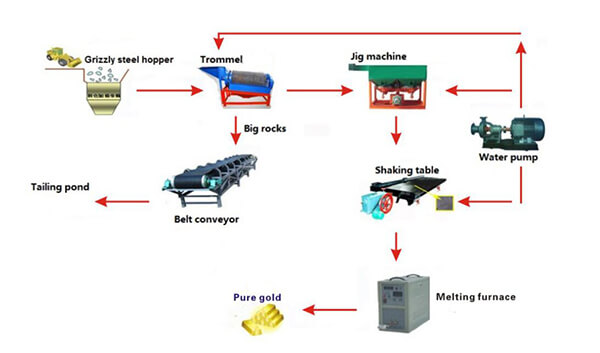

The gold ore beneficiation process can be broadly divided into four main stages: crushing, grinding, separation, and drying. The equipment used in each stage is as follows:

1.Crushing Equipment

The primary equipment for crushing gold ore includes jaw crushers, impact crushers, and cone crushers. Jaw crushers are typically used for initial crushing due to their high crushing strength and capacity, capable of reducing materials to 50mm in size. Secondary crushing can be performed using either impact crushers for softer materials or cone crushers for harder materials.

2.Grinding Equipment

Ball mills are the main equipment used in the grinding stage. The goal is to separate the valuable components of gold ore from the gangue, providing optimal conditions for the subsequent separation stage and enhancing the beneficiation grade of the gold concentrate.

3.Separation Equipment

The gold extraction method typically combines gravity separation and flotation. This approach is economical, reasonable, and scientifically sound, significantly improving the recovery of gold concentrate. The primary equipment used includes flotation machines and spiral classifiers. Spiral classifiers are used to classify finely ground stone powder, with larger particles being returned to the ball mill for further grinding. The flotation machine, with the aid of relevant reagents, extracts high-grade gold concentrate slurry.

4.Drying Equipment

To utilize the gold concentrate slurry effectively, its physical state must be altered. This involves precipitation, concentration, drying, and dehydration using equipment such as dryers, thickeners, and dehydrators.

The whole process flow of gold ore beneficiation is mainly into four stages: crusher, grind, separator, and dry. The equipment used in each stage is as follows:

Cost Considerations for Gold Mining Equipment

The cost of a set of gold mining equipment can range from US$30,000 to $900,000. The wide price range is due to several factors, including the size of the gold ore blocks and the complexity of the gold mining process. For instance, smaller ore blocks may only require a single jig, while larger operations may need a full crushing setup with additional equipment.

Other factors influencing the price include the design of the gold processing line, the scale and reputation of the gold beneficiation manufacturer, and geographical and market conditions. Consulting with experts like Dasen Mining can provide comprehensive services to ensure high-quality equipment at a reasonable price.

In conclusion, understanding the gold mining process and selecting the right equipment are crucial for efficient and profitable gold extraction.

Contact Information:

Whatsapp:+86 133 1927 7356

<strong><a href=”mailto:[email protected]”>Email:[email protected]</a></strong>