Using ore slag and barren solution for pit leaching?

Pit leaching, a widely used method in gold mining, offers a simple process with lower equipment investment and costs compared to other methods. Its high recovery rate and quick effects make it an attractive option for gold extraction. However, while the process may seem straightforward, it involves several critical factors that must be carefully considered.

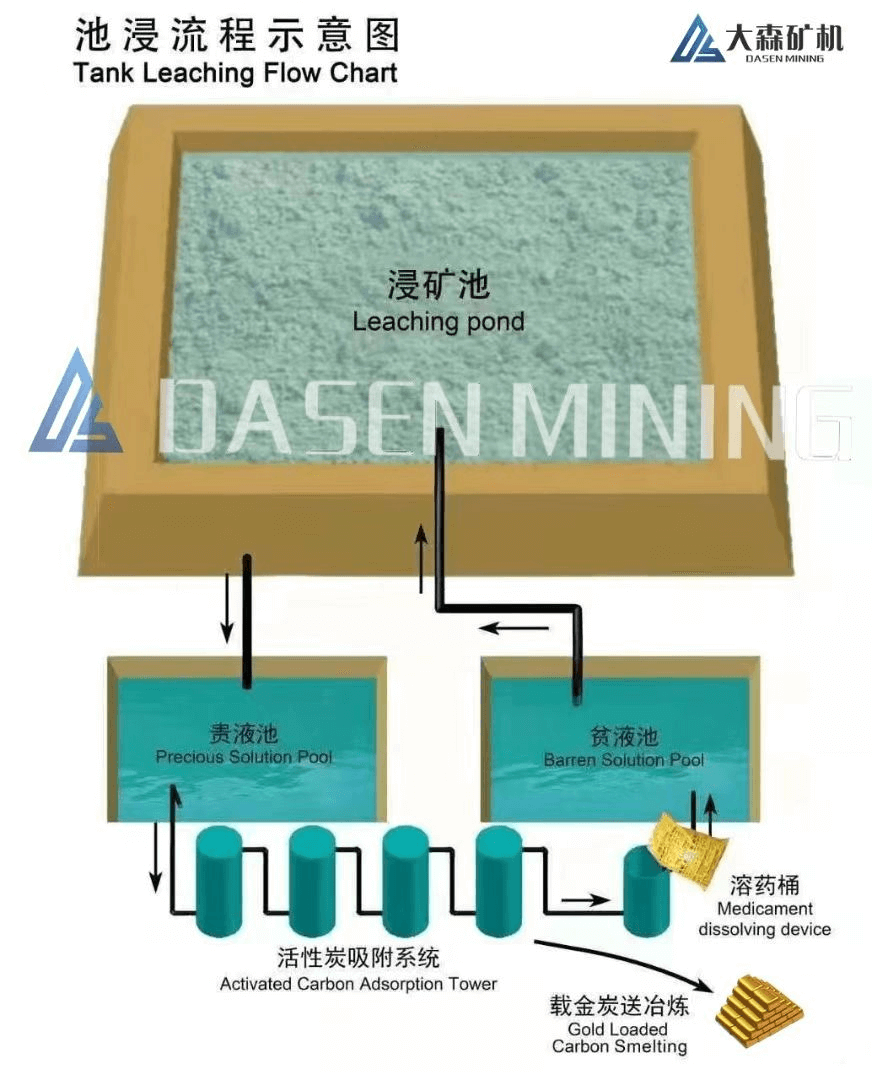

The Pit Leaching Process

The pit leaching process involves creating a leaching pit where ore is placed and exposed to a leaching solution. This solution, often containing cyanide, dissolves the gold from the ore. Under normal conditions, the leaching solution or barren solution can be recycled multiple times. However, if the ore contains harmful elements or heavy metals, the barren solution may need to be replaced to prevent contamination and maintain the leaching efficiency.

Challenges and Considerations

While pit leaching offers several advantages, it also presents certain challenges. One significant issue is the potential for environmental contamination if not managed properly. The presence of harmful elements like arsenic and copper in the ore can lead to the contamination of the barren solution and subsequent pollution of the environment. To mitigate this risk, it is essential to carefully monitor and treat the barren solution before discharge.

Another factor to consider is the impact of ore quality on the leaching process. The presence of impurities or contaminants in the ore can affect the leaching efficiency and recovery rate. Therefore, it is crucial to assess the ore quality before initiating the pit leaching process.

The Role of Professional Expertise

Given the complexity of pit leaching and the potential challenges involved, it is essential to have professional expertise to ensure successful implementation. Our company offers over 30 years of experience in pit leaching projects and provides comprehensive technical services. From pit construction to gold extraction, our team can guide you through the entire process and help you achieve optimal results.

Conclusion

Pit leaching remains a valuable method for gold extraction. However, its success depends on careful planning, proper implementation, and attention to detail. By understanding the intricacies of the process and seeking professional guidance, you can maximize the benefits of pit leaching and ensure a sustainable and profitable gold mining operation.

We can provide you with more information about the leaching pit. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]