Description

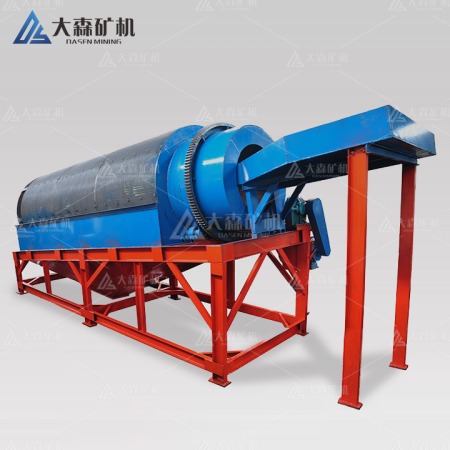

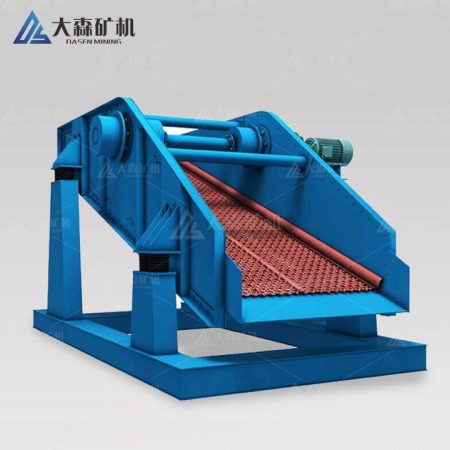

Product Name: Drum Screening Machine, Trommel Screen, Mobile trommel screen, Trommel separator

Product material: conventional manganese steel can be customized

Feed particle size: 1-200mm

Processing capacity: 10-800T/h

Product use: screening of sand and gravel materials

Trommel Screen Structure:

A closed trommel screen primarily consists of a motor, reducer, trommel drum, frame, sealing cover, inlet, and outlet. Widely employed in material sorting processes, the trommel screen excels at separating particles based on size with high precision. The cylindrical drum is typically divided into multiple sections. Depending on specific requirements, these sections feature sieve holes arranged in ascending order, with each section maintaining a consistent aperture size.

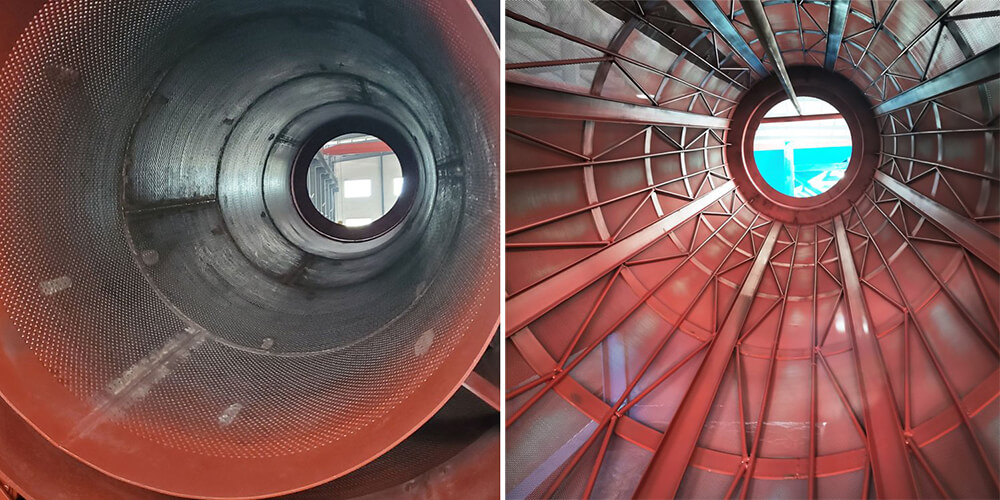

A cylinder is made of wire mesh or perforated steel plate, and it rotates around a flat axis or an inclined axis.

Application:

Trommel separators excel at classifying materials by particle size and find extensive use in industries such as electric power, mining, metallurgy, construction, and chemicals. They are particularly effective in processing refractory materials, coal, sand, quarry stones, and challenging substances like sticky or wet coal, coke, white ash, and placer gold ore to achieve uniform product gradations.

Features:

- Innovative Design: Employing a multi-stage cylindrical screen structure, our trommel separator significantly boosts capacity to 120t/h compared to traditional single-cylinder models, while maintaining a 30% opening rate.

- Enhanced Efficiency: The rectangular screen design offers a 3.6 times larger effective working area than conventional cylindrical screens, resulting in superior performance.

- Reduced Wear: Our multi-stage, multi-copy plate configuration minimizes material friction, extending equipment life and lowering maintenance costs.

- Energy Efficient: Optimized mechanical transmission and structural design allow for operation with a smaller power motor.

- User-Friendly: The compact, stable design of our trommel separator simplifies operation and maintenance. A mesh surface follow-up device effectively reduces blockages.

- Versatile Application: Constructed with wear-resistant sieve plates, our trommel separator can handle abrasive, hard, and heavy materials without compromising mesh integrity.

Advantages:

- Efficient and Durable: Employing a rolling conveying principle, this equipment minimizes friction and abrasion, reducing screen blockage and extending screen life.

- Smooth Operation: The integral through-shaft structure ensures smooth, vibration-free, and quiet operation of the roller supports.

- Easy Maintenance: A split design of internal drum screen components allows for quick and convenient replacement and maintenance.

- Environmentally Friendly: Fully sealed drum bodies prevent dust and pollution, creating a clean operating environment.

- Energy Efficient: Featuring deceleration transmission, this machine boasts high transmission efficiency, low power consumption, and significant energy savings.

- Customization: A wide range of screen materials and hole sizes can be tailored to specific customer requirements, ensuring high screening efficiency, long service life, and minimal maintenance costs.

| Model | Capacity

(tph) |

Power(kw) | Drum diameter(mm) | Drum length(mm) | Screen size(mm) | Dimension(mm) | Weight(t) |

| DME-0510 | 1-10 | 1.5 | 500 | 1000 | <3-10 | 1800*1020*1500 | 1.0 |

| DME-1015 | 5-20 | 4.0 | 1000 | 1500 | 3000*1400*2145 | 2.2 | |

| DME-1020 | 10-40 | 5.5 | 1000 | 2000 | 3460*1400*2145 | 2.8 | |

| DME-1225 | 20-60 | 7.5 | 1200 | 2500 | 4146*1600*2680 | 4.2 | |

| DME-1530 | 30-90 | 11 | 1500 | 3000 | 4460*1900*2820 | 5.1 | |

| DME-1545 | 50-120 | 15 | 1500 | 4500 | 5960*1900*3080 | 6.0 | |

| DME-1848 | 70-180 | 22 | 1800 | 4800 | 6500*2300*4000 | 7.0 | |

| DME-1860 | 80-200 | 22 | 1800 | 6000 | 8000*2300*4000 | 7.5 | |

| DME-2055 | 120-250 | 30 | 2000 | 5500 | 7500*2500*4000 | 8.6 |

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]