Description

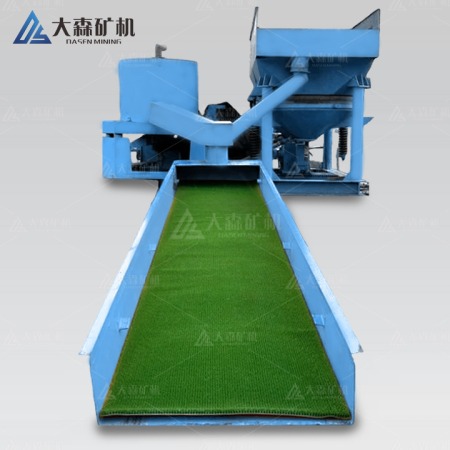

A Jig concentrator is one of the main methods of gravity beneficiation.

Jigging is a beneficiation process that utilizes jigs to separate materials primarily based on density differences. This is achieved by subjecting the material to a pulsating water or air flow within the jig. While hydraulic jigging (using water) is more common, wind jigging (using air) is also a viable method. Particle size and shape also influence separation efficiency.

The jigging process involves continuously feeding the ore onto a sieve plate within the jig chamber. As the water flow is periodically pulsed upward through the sieve plate, the material bed becomes fluidized. When the water flow subsides, the heavier minerals settle to the bottom while lighter minerals concentrate towards the top. This stratification allows for the separate collection of concentrates and tailings.

Working Principle

Hydraulic jig machines are classified into five primary types based on their structural differences and water movement mechanisms: piston, diaphragm, pistonless, hydraulic agitation, and moving screen.

Optimal for processing coarse-grained ores, jig separators handle particle sizes ranging from 50mm down to 0.2-0.074mm, with the most efficient range being 18-2mm. Widely applied in coal preparation and the extraction of tungsten, tin, and gold, jig separators also find utility in iron, manganese, and certain non-metallic ore processing.

Product Features:

- Exceptional processing capacity, accommodating a wide range of particle sizes: Efficiently handles materials with various particle sizes to meet diverse production needs.

- High enrichment ratio and high recovery rate: Effectively increases the concentration of target substances, reducing resource waste.

- Easy installation, operation, and maintenance: User-friendly design lowers the barrier to use.

- Variable frequency drive motor: Enables precise control of equipment operating speed, improving production efficiency.

- Low water consumption: Reduces production costs and protects the environment.

High recovery jig models

| AM30 | AM30 type is a large particle jig, mainly used for processing coarse iron ore. |

| JT1070-2 | Jt1070-2 type is a sawtooth wave jig, which is named because the pulsation curve produced by stirring water is a sawtooth wave type. It is mainly used for jigging gravity separation of various fine-grained minerals and has a very good beneficiation effect on fine-grained minerals. |

| LTA-1010/2 | LTA-1010/2 type is a single row double chamber down moving conical diaphragm jig, so it is also called double chamber jig, which has a very good beneficiation effect on 0-8mm minerals. |

| LTP34/2 | Ltp34/2 type is a small side-moving jig, widely used in river gold and iron sorting. |

Jigs offer several advantages, including high separation efficiency, high capacity, and versatility in enrichment.

Key factors influencing jig performance include ore particle size, pulp density, flushing duration, and flushing water volume.

You can send us a private letter if you don’t know anything about the jig concentrator:

Whatsapp:+86 133 1927 7356

Email:[email protected]