Description

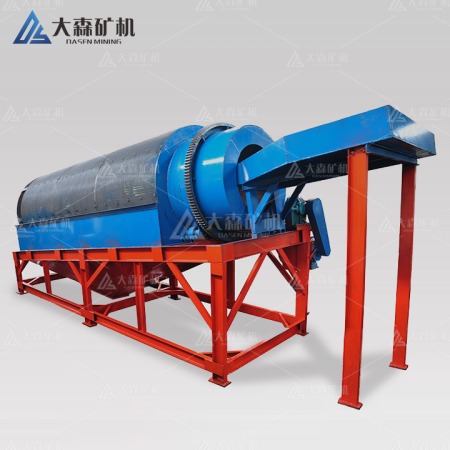

Name: Cyclone, Hydrocyclone, Hydrocyclone Separation

Model: various models

Material: Polyurethane/Steel

Features: high concentration, long life

Uses: classification, de-sanding and desilting, concentration, dehydration

Applicable occasions: mining, power plant, metallurgy, chemical industry, construction and maintenance work.

Hydrocyclones are essential equipment in gold leaching circuits, providing efficient and reliable solid-liquid separation. These centrifugal devices utilize a tangential feed to create a high-speed vortex, separating slurry into fine overflow and coarse underflow fractions. By accelerating particle settling, Hydrocyclone Separation enhance gold recovery by improving leach solution clarity, optimizing reagent consumption, and facilitating subsequent processing steps. Their robust design, low maintenance, and high throughput make them indispensable for gold extraction operations.

Hydrocyclones offer several key advantages in mineral processing:

- Optimized Feed Entry: The involute, tangent, and spiral feed design minimize turbulence, ensuring smooth fluid flow within the cyclone and enhancing separation efficiency.

- Enhanced Classification: The carefully balanced cone column length and overflow pipe depth significantly improve the cyclone’s ability to classify particles accurately.

- Reduced Overflow and Underflow Contamination: The specialized overflow pipe and cone structure effectively mitigate the issues of coarse particles in the overflow and fine particles in the underflow.

- Facilitated Commissioning: The precise dimensions of the overflow pipe and bottom orifice streamline on-site setup and operation.

| Model | Overflow

gate (mm) |

Settling sand gate(mm) | Cone angle(º) | Max feeding size(mm) | Feeding pressure

(Mpa) |

Capacity

(m³/h) |

Separation size (um) | Weight

(kg) |

||||||

| FX25 | 5-8 | 2-6 | 3 | 5 | 0.2 | 0.1-0.3 | 0.6-1.5 | 2-10 | 5/7 | |||||

| FX50 | 11-8 | 3-12 | 10 | 6 | 0.3 | 0.1-0.3 | 2-4 | 5-74 | 10/14 | |||||

| FX75 | 15-20 | 4-12 | 10 | 7 | 0.6 | 0.1-0.3 | 5-7 | 5-74 | 17/27 | |||||

| FX100 | 20-40 | 8-18 | 15 | 10 | 7 | 1 | 0.1-0.3 | 12-23 | 10-100 | 17/27 | ||||

| FX125 | 25-40 | 8-18 | 10 | 7 | 1 | 0.1-0.3 | 15-26 | 20-100 | 35/38/45 | |||||

| FX150 | 30-50 | 8-25 | 15 | 10 | 7 | 1.5 | 0.05-0.3 | 18-30 | 20-74 | 45/50 | ||||

| FX165 | 35-55 | 40-45 | 8 | 2 | 0.05-0.3 | 25-40 | 40-100 | 42/48/55 | ||||||

| FX200 | 40-65 | 16-35 | 15 | 10 | 2 | 0.06-0.3 | 30-50 | 30-100 | 60/65/73 | |||||

| FX250 | 60-120 | 16-40 | 20 | 15 | 10 | 3 | 0.06-0.3 | 53-60 | 30-100 | 110/123/140 | ||||

| FX300 | 65-120 | 25-50 | 20 | 15 | 5 | 0.06-0.2- | 50-90 | 40-150 | 125/172 | |||||

| FX350 | 80-120 | 30-70 | 180 | 20 | 15 | 6 | 0.06-0.2 | 60-120 | 50-150 | 180/211/240 | ||||

| FX400 | 120-140 | 55-65 | 20 | 15 | 0.03-0.2 | 80-150 | 74-150 | 310 | ||||||

| FX500 | 130-220 | 35-100 | 180 | 20 | 10 | 10 | 0.05-0.2 | 140-220 | 74-200 | 450/550/636 | ||||

| FX550 | 150-180 | 80-100 | 20 | 11 | 0.06-0.15 | 180-240 | 55-120 | 710 | ||||||

| FX610 | 160-220 | 80-110 | 20 | 12 | 0.04-0.15 | 200-260 | 74-200 | 840 | ||||||

| FX660 | 180-240 | 80-150 | 20 | 15 | 0.04-0.15 | 250-360 | 74-220 | 1100 | ||||||

| FX710 | 240-280 | 120-160 | 20 | 15 | 0.04-0.15 | 400-550 | 74-250 | 1230 | ||||||

| FX850 | 280-360 | 130-220 | 20 | 22 | 0.04-0.15 | 500-900 | 74-350 | 2400 | ||||||

1. Hydrocyclone Separation Purpose

Hydrocyclones are widely used classification devices in mineral processing industries. Primarily employed for pulp classification, separation, concentration, and desliming, hydrocyclones often integrate with mills to form efficient grinding and classification systems. Additionally, they find application in desliming processes within gravity concentration plants and tailings dewatering operations.

2. Application

Hydrocyclones offer several advantages. Their simple, moving-part-free design ensures easy operation and maintenance. Renowned for high classification efficiency exceeding 80%, hydrocyclones deliver fine particle classification suitable for industrial demands. Furthermore, their low cost, minimal material consumption, and high economic value make them a preferred choice.

3. Precautions in Cyclone Adjustment:

- Valves should always be fully open or closed, avoiding partially open positions.

- Combined adjustment methods are generally preferred over isolated adjustments.

- Diagonal opening of the cyclone is recommended.

Whatsapp:+86 133 1927 7356

Email:[email protected]