Description

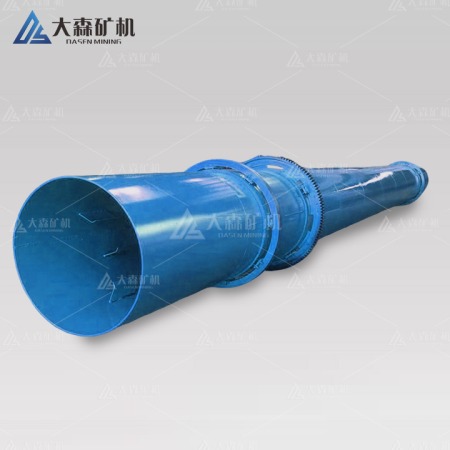

Name: tumble dryer, rotary drum dryer, industrial rotary dryer

Feed moisture: 30-80%

Discharge moisture: 10-15%

Product advantages: improve thermal efficiency by more than 40%

Heating method: coal or biomass

Scope of application: construction, agriculture, mining

Structure: cylinder, front roller, rear roller, gear, blocking roller, drag roller, pinion, discharge part, lifting plate, reducer, motor, hot air duct, feeding chute, furnace body and other parts.

Rotary drum dryers are industrial equipment primarily used to reduce moisture content in wet materials. They consist of a rotating cylinder equipped with internal lifting devices. Hot air is circulated the drum to evaporate moisture from the material as it tumbles within.

Beyond the standard rotary drum dryer, variations include three-cylinder dryers and specialized units like slag and iron powder dryers. These options provide flexibility to cater to diverse customer requirements.

Applications

Industrial rotary dryer excel at processing granular materials that tolerate high temperatures without chemical alteration or discoloration. Common applications include:

- Construction: Drying yellow sand for dry powder mortar and various sand grades for casting.

- Cement: Drying black furnace slag.

- Chemical: Drying small granular clay particles.

Rotary dryers can achieve final moisture content below 1% in many industries.

Working Principle of a Rotary Dryer

Industrial rotary dryer are single-chambered industrial dryers consisting of a rotating cylindrical drum. Wet material enters from one end and exits dry from the other. The drying process occurs concurrently with the thermal flow. Material tumbles inside the drum as it progresses, maximizing contact with hot air for efficient drying. Compared to triangular dryers, rotary dryers offer a larger surface area for drying. Additionally, the cylindrical design facilitates easier cleaning of residual material.

During operation, the rotary dryer’s internal temperature reaches a range of 400°C to 800°C. Wet material is fed through the feed port. A heating element, typically located at the bottom of the drum (ensuring efficient heat exchange), generates hot gas that flows upwards through the drum, coming into direct contact with the material. This heat transfer process continuously raises the material’s temperature, causing moisture to evaporate.

| Specs(m) | Capacity(T/H) | Motor | Main reducer | Weight(T) | ||

| Power(KW) | Model | Model | Speed ratio | |||

| Φ1.2×10m | 2.5 | 7.5 | Y160M-R3 | ZL50-16-I | — | 13.5 |

| Φ1.5×12m | 3.3-4.9 | 10 | Y160L-6-B3 | JZQ500-Ⅲ-2F | — | 18.9 |

| Φ1.5×15m | 4-6 | 18.5 | Y200L1-6 | JZQ500-Ⅲ-2F | — | 21 |

| Φ1.8×12m | 4-6 | 18.5 | Y160L-6 | ZQ50-16Ⅱ-2 | 16.46 | 23 |

| Φ2.2×12m | 7-12 | 18.5 | Y200L7-6 | JZQ650-Ⅲ | 31.5 | 38 |

| Φ2.2×14m | 7-12 | 22 | Y200L7-6 | JZQ650-Ⅲ | 31.5 | 40 |

| Φ2.2×16m | 12 | 30 | Y225M-6 | JZQ750-Ⅲ | 31.5 | 45 |

| Φ2.4×14m | 12 | 30 | Y250M-6 | JZQ750-Ⅲ | 31.5 | 51 |

| Φ2.4×18m | 10-13 | 37 | Y250M-6 | ZL85-13-I | 27.16 | 54 |

| Φ2.4×20m | 10-14 | 37 | Y250N-6 | ZL85-13-I | 27.16 | 55 |

| Φ3×20m | 25 | 55 | Y250M-4 | ZL100-16-I | 41.52 | 78 |

| Φ3×25m | 32-36 | 75 | YR280M-4 | ZL100-16-I | 41.52 | 105 |

Performance Characteristics:

- Efficient Drying Process: The dryer employs a smooth drying method that combines radiation, thermal flow, conduction, and heat exchange for optimal performance.

- Compact Design: The dryer’s surface area is reduced by over 30% compared to traditional models, resulting in a more compact footprint.

- Wide Application Range: Versatile in its application, the dryer is suitable for drying various materials, including coal, oil, gas, clay, coal slag, and iron powder.

- Uniform and Efficient Heating:

Main Internal Structure of Industrial Rotary Dryer: Lifting Plates

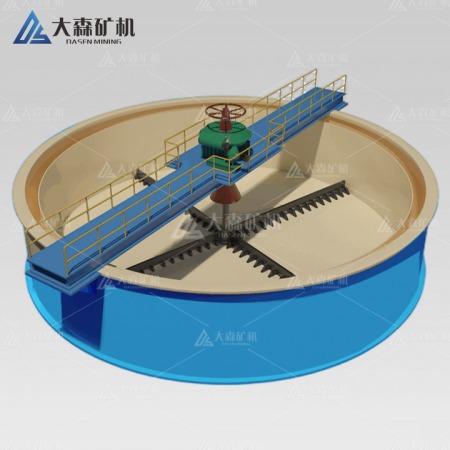

Lifting plates are essential components within industrial rotary dryers, designed to optimize material-to-drying-medium contact by evenly distributing material across the drum’s cross-section. Several lifting plate types cater to different material characteristics:

- Standard Lifting Plate: Suitable for large or adhesive materials, ensuring consistent exposure to the drying medium.

- Two-Format Lifting Plate: Ideal for dense, non-brittle materials that resist dispersion. This plate divides the drum into four isolated, fan-shaped compartments, enhancing material turnover.

- Cross-Shaped or Frame-Shaped Lifting Plate: Designed for dispersing small, brittle materials, promoting even distribution throughout the drum.

- Double Heat Transfer (or Semi-Diameter Heating) Dryers: Employ this lifting plate type to maximize heat exchange efficiency.

- Sub-Format (Fan-Shaped) Lifting Plate: Minimizes powder accumulation and material carryover by creating a fan-shaped lifting area. The reduced falling height of the material limits its exposure to the drying gas, preventing excessive powder entrainment.

We can provide you with more information about Gold Ore Plant Solution. If you have any questions, please contact:

Whatsapp:+86 133 1927 7356

Email:[email protected]