Description

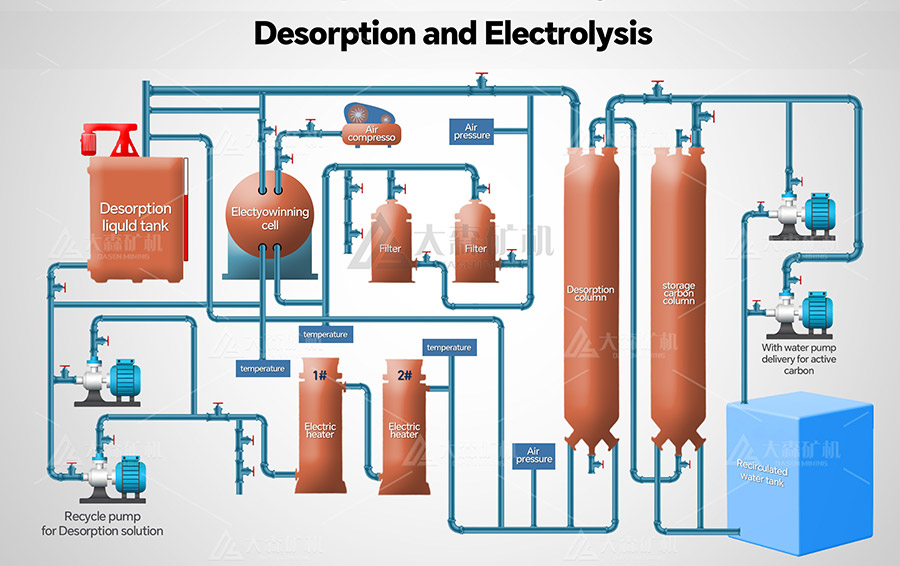

A gold ore desorption electrolysis plant is a set of gold ore beneficiation equipment that obtains gold mud from gold-loaded carbon through desorption and electrolysis under High temperature and high-pressure conditions. This equipment can well desorb the gold-loaded carbon produced by the gold CIP/CIL plant and heap leaching, vat leaching plant.

Advantage:

- Low energy consumption: The desorption electrolysis temperature is the same, no heat exchange is needed, and the electricity consumption is 1/4 ~ 1/2 of that of the conventional system because of the fast working speed.

- Reduce the cost of carbon regeneration

The non-toxic desorption composite reagent contains a carbon activator, which can regenerate the carbon, and the poor carbon does not need fire regeneration, thus saving the cost of carbon regeneration

- Less pollution: The desorption solution does not need to add sodium cyanide, low cost, less pollution;

- Gold mud in high grade: High-grade gold mud, no reverse electrolysis, the gold mud grade max to 70%;

- Safety: With triple safety protection measures, that is, the system itself is intelligent, automatic pressure limit, force release mechanism, and safety valve.

Desorption Electrolysis System Working Principle

For the analytical electrolysis system; we add easily activated carbon adsorption of anions in the desorption system, so that AU (CN)2-replacement out, the realization of the desorption of gold. The precious liquid obtained by desorbing gold-loaded carbon is recovered by the ionization method, thus solid gold is obtained.

This system is mainly composed of two major parts: part 1: Desorption and part 2: Electrolysis.

The process of desorption and electrolysis is separated so that the solvent is carried out in a comprehensive desorption tower, and the electrolysis of precious liquid is carried out in an independent electrolytic cell, the four processes of solvent desorption, heating of precious liquid, solvent condensation and solvent recovery are arranged in a comprehensive desorption tower, while the precious liquid obtained by solvent vapor desorption after carrying gold charcoal is conducted to electrolysis in a separate electrolytic cell through a pipeline, to get rough gold, and then purified to get finished gold.

Desorption Electrolysis Process Detailed Procedure

(Below information is industrial knowledge, if you want to know more, please kindly contact us via Mobile/Whatsapp:+008618192208207)

- After pretreatment, the carbon loaded with gold enters the linear vibrating screen, and the carbon powder flows away with the liquid. The smaller particle size that is not suitable for the desorption process is collected under the screen, and the material on the screen enters the carbon storage tank. The carbon slurry entering the carbon storage tank cannot contain mud and impurities. The position of the carbon storage tank should be at the upper end of the desorption column. After the connection valve is opened, it is added to the desorption column.

- Water and sodium hydroxide are added to the analytical solution tank. The ratio needs to be determined according to the scale of the gold-loaded carbon to be processed. The height of the liquid is about 30-40 cm from the top of the tank, and the liquid flows into the circulating pump (2 circulating pumps should be prepared, one of which is for standby), which is pumped into the heater (two heaters are connected in series) to heat the liquid to 150°C.

- After the liquid is heated, it reaches the bottom of the desorption column and mixes with the gold-loaded carbon, flows up through the carbon layer, and then overflows from the overflow pipe. The overflowing liquid enters the filter to filter out the mud and impurities inside. When the liquid in the electrolytic tank is full, the valve of the analytical liquid tank will automatically close, and no more liquid will be injected. The overflow in the electrolytic tank enters the circulating pump again, and the whole process takes 6-8 hours.

- When the temperature drops to about 110℃, the electrolytic cell starts to energize and restore the gold mud. After this process, the carbon can be released. At this time, the carbon is no longer gold-loaded carbon, and will return to the adsorption process to continue working, and the gold sludge is deposited in the electrolytic cell.

- The whole system stops running, the pressure is removed, and the temperature drops. At this time, the electrolytic cell can be opened, and the cathode inside can be taken out, washed with clean water, collected washed things, treated with acid, removed impurities, purified, dried, and smelted. After all these processes, the entire desorption electrolysis process of the gold-loaded carbon is completed.

The above is the introduction of the desorption and electrolysis process of gold-loaded carbon. The desorption and electrolysis equipment independently developed by DasenMining has a series of advantages, including a high desorption rate (6-8 hours), good desorption effect (resolution rate above 98%), and low power consumption (1/2-1/4 of conventional equipment), less environmental pollution (no cyanide).

Note: In this process, to make the whole system enter the high-temperature and high-pressure environment as soon as possible, the air compressor will pressurize after the normal cycle. Pressurization aims to increase the boiling point, thus increasing the pressure throughout the system.

Main Technical Parameter

| Model:300kgs, 500kgs, 1000kgs etc. | ||

| 1. Desorption solution: ph > 13.5 | 2. Use batch: infinite times | 3. Start of electrolysis: 100-110 ° c |

| 4. End of electrolysis: 150 ° c | 5. Electrolytic current: 350-1250a | 6. Electrolytic voltage: 2-4v |

Dasen Gold Leaching Factory Video

Recently Shipping

Container type 300kgs desorption electrolysis shipped to Pakistan

Whatsapp:+86 133 1927 7356

Email:[email protected]