Description

The three-roller magnetic separator is a dry-type magnetic separator. The magnetic roller is made of high-performance permanent material rare earth NdFeB through polymerization. It consists of three different diameters and a magnetic field intensity roller, the upper one is a 1200Gause magnetic roller, which can separate strong magnetic minerals like iron, the middle one is a 7000-8000Gause magnetic roller, which can separate weak magnetic minerals like titanium, the lower one is a 10000-11000Gause magnetic roller which can separate some rate earth minerals like monazite.

Application

Three rollers magnetic separator is a dry type high-intensity magnetic separator, it is one of the newest permanent magnet machines on the market, mainly used for the separation of zircon sand, ilmenite, titanium, monazite, etc… these minerals in different magnetism.

Three Roller Magnetic Separator Structure

This equipment is a new type of permanent magnetic separator, the drum and separation plate, adopt non-conductive magnetic material stainless steel material, the drum end cover uses aluminum casting, and other parts use steel. It consists of a feeding port, three magnetic roller and discharging ports, and an electrical controller.

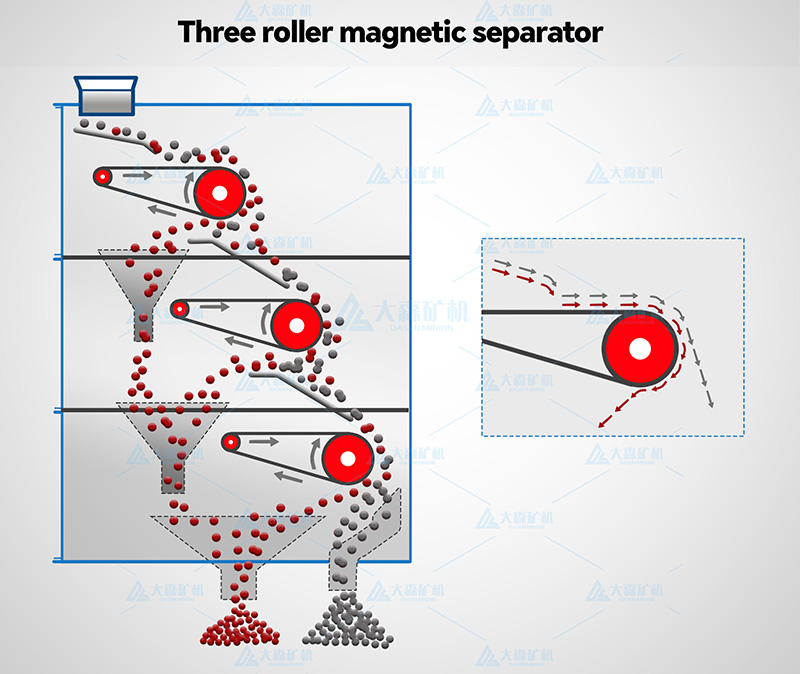

Working Principle

Below is professional mechanical knowledge, if you can not understand very well, you can directly contact us:+86-13319277356.

1. The first roller is a weak magnetic roller mainly used for iron removal. Minerals must be screened before entering the magnetic separator, otherwise the material will not be evenly discharged, affecting the recovery and quality of mineral products. All motors are variable frequency-controlled speed-regulating motors. The first-stage iron removal must be cleanly sorted, otherwise, the iron ore will fall on the second-stage medium-strong magnetic roller, which will wear the rust-free steel shell and shorten the life of the main machine.2. The middle roller is a medium-strong magnetic drum, mainly used to sort the weakly magnetic minerals after the first iron removal stage. The weakly magnetic minerals fall from the top to the surface of the strong magnetic drum, are adsorbed on the drum, rotate along the drum’s direction to the magnetic system’s edge, and fall into the magnetic mineral concentrate bucket. The drum speed can be adjusted to adjust the grade and recovery rate of the magnetic product.

3. The magnetic field strength of the third-level strong magnetic drum is very high, above 10,000GS. After the second magnetic separation, if there are particularly weak magnetic ores that are not selected, these minerals will be recovered on the strong magnetic drum. The recovery rate of mineral products can also be adjusted by adjusting the number of revolutions of the magnetic drum.

Parameter(We introduce the DS200-300 model as our hot sale one. )

| Model | Magnetic field intensity | Effective working length | Weight | Driving motor | Dimension |

| 220-300

|

1000-1200Gause

7000-8000Gause 10000-11000Gause |

900mm | 1000kg | 1.5kw | 1500mm×1550mm×2700mm |

1. Feeding size≤3mm

2. Power:380v, three phases four wires

3. Capacity:1-1.5tons per hour.

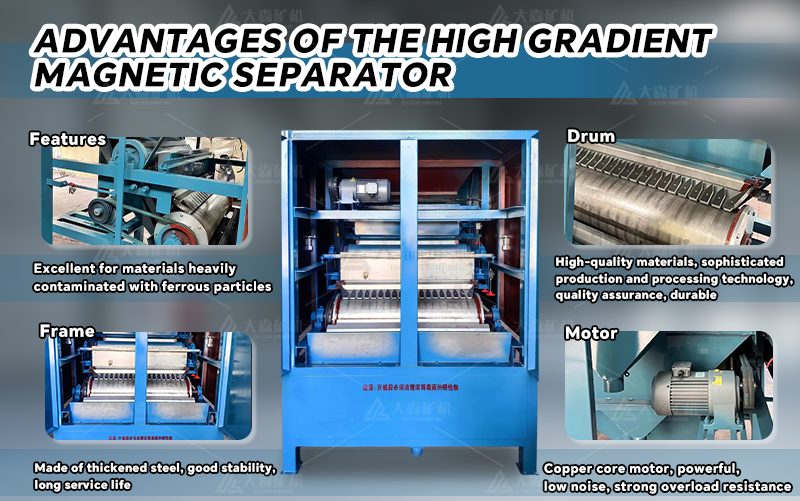

Three Roller Dry Magnetic Separator Advantages

- The permanent magnetic three-roller strong magnetic separator significantly separates coexisting minerals with strong, medium, and weak magnetism.

- It has a small footprint, high efficiency, simple and robust operation, durability, and easy and simple installation.

- It can perform magnetic separation of multiple minerals at once.

- Compact structure, large processing capacity, convenient operation, and easy maintenance.

Recently Shipping

Whatsapp:+86 133 1927 7356

Email:[email protected]