Description

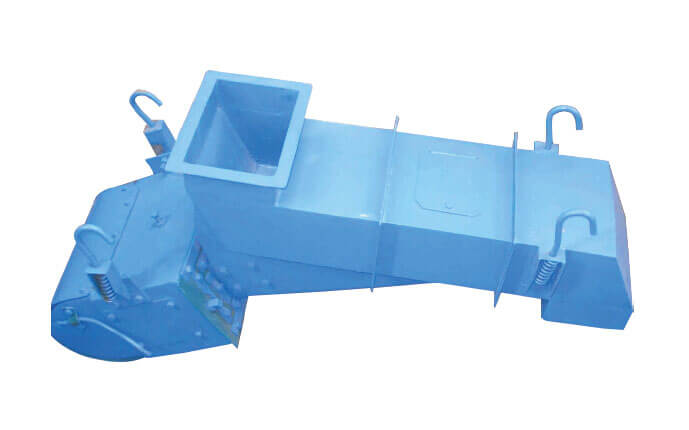

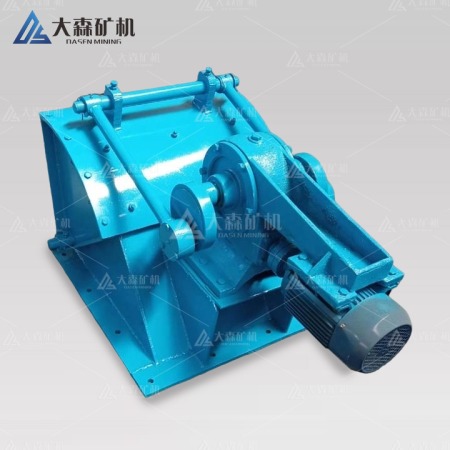

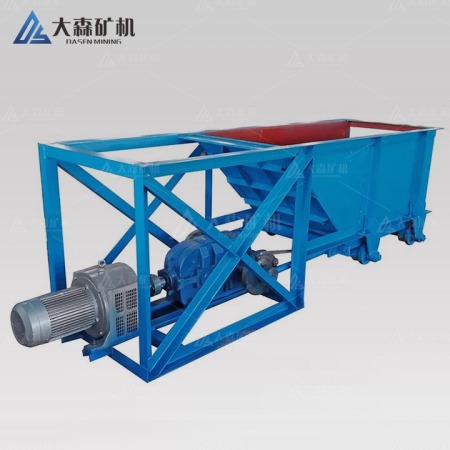

Name: electromagnetic vibration feeder, Electromagnetic Vibrating Feeder

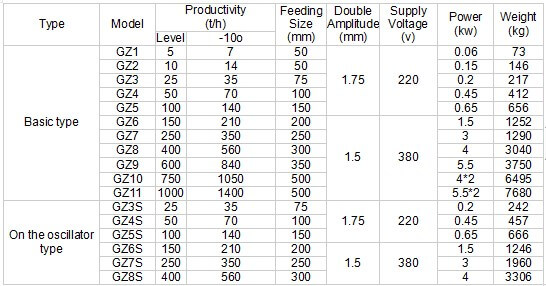

Productivity: 5-1400t / h

Power: 0.1-13kw

Particle size: 50mm-500mm

Basic models: (gz1–gz11), up vibration type, closed type, light groove type, flat groove type, wide groove type, round tube type, and extra large type.

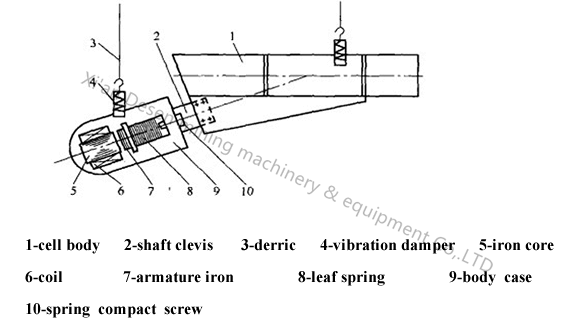

Structure: electromagnetic vibration feeder is composed of material trough, electromagnetic vibrator, shock absorber and control box.

Feeding mode: Automatically control the production process and feed to the receiving device (equipment) evenly, continuously, or quantitatively.

The GZ series electromagnetic vibration feeders are used in mining, metallurgy, coal, building materials, light industry, chemical industry, electric power, machinery, grain, and other industries to feed block, granular, and powdery materials evenly, continuously or quantitatively. It also allows for step-less adjustment of feeding quantity, centralized control, and automatic production process control.

Electromagnetic Vibrating Feeder Working Principle:

A single-phase half wave rectifies the current of the electromagnetic coil of the electromagnetic vibrating feeder. A pulse electromagnetic force is generated between the armature and iron core when the coil is connected, and a current flows through the positive half cycle. The slot moves backward and the main spring of the exciter deforms, storing a certain amount of potential energy. When there is no current flowing through the negative half cycle coil, the electromagnetic force disappears, and the main spring releases energy, causing the armature and iron core to move away from the slot.

Due to this, the electromagnetic vibration feeder vibrates back and forth at the frequency of the AC power supply. Material in the tank moves continuously along the trajectory of parabola because the bottom plane of the tank is at an angle to the action line of the exciting force. It is possible to control the feeding volume of the equipment by adjusting the rectifier voltage.

Magnetic vibration feeders possess several advantageous attributes:

- Compact and efficient design: Characterized by small size, lightweight construction, and simple assembly, these feeders require minimal maintenance and operational costs due to the absence of rotating components and lubrication.

- Precise material flow control: Operating near resonance frequency, the feeder ensures accurate material feed rates through instantaneous flow adjustments and on/off capabilities.

- Centralized control: Integration into automated systems is facilitated by the feeder’s compatibility with centralized control systems.

- Durability: The feeding trough exhibits minimal wear, while alloy steel options provide resistance to high temperatures, abrasion, and corrosion.

- Limitations: It is essential to note that magnetic vibration feeders are not explosion-proof.

If you have ideas or questions about gold process plant and industrial processing equipment, please contact us:

Whatsapp:+86 133 1927 7356

Email:[email protected]