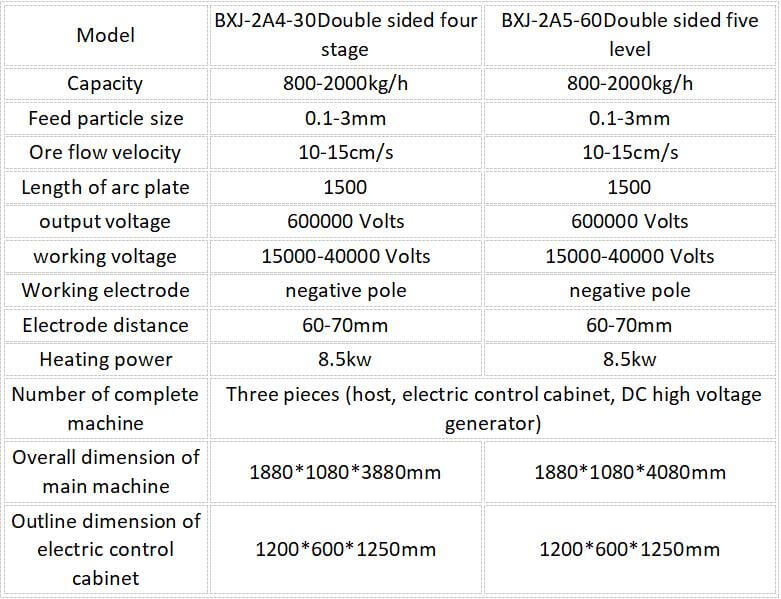

Description

Name: four-layer arc plate electric separator / Four Rollers High Tension Electrostatic Separator

High voltage regulation: 0-30-60kv

Motor power: 1.5kw

Processing particle size: < 2mm-20mm

Weight: 1.5T

Main accessories: time relay, current relay, voltage regulator, temperature controller set, beneficiation drum, heating pipe, wool felt, electrode wire, high voltage cable, high voltage porcelain insulator, transformer.

This electrostatic separator leverages the disparity in mineral conductivity and the influence of electric fields to facilitate mineral sorting. By exploiting these fundamental differences, the machine effectively separates conductive from non-conductive minerals, generating high-purity concentrates of both types, such as rutile and zircon.

Compatible with single-disc, double-disc, permanent magnet, and electromagnetic systems, this versatile equipment extends its applicability beyond standard mineral separation. The separator’s ability to process high-phosphorus ore and refractory rutile is enhanced by its integrated 0-45,000 volt high-voltage generator.

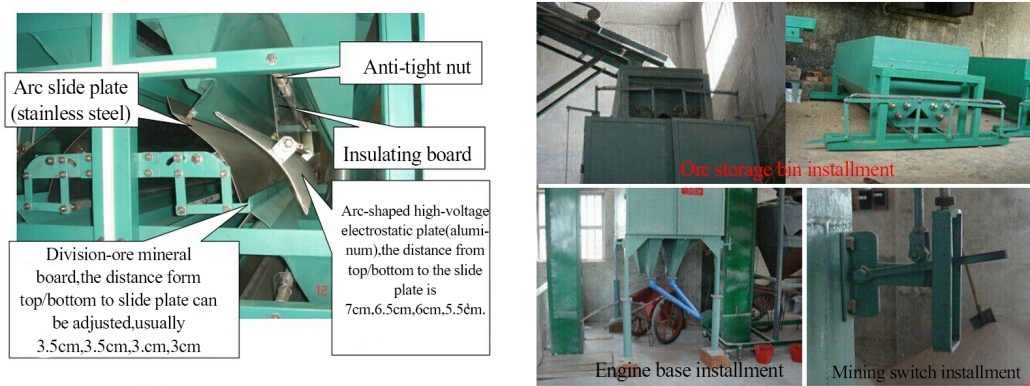

Working Principle of Arc Plate Electric Separator

The arc plate electric separator employs a two-row, four-floor structure equipped with stainless steel grounding arc slides on each level. A high-voltage, adjustable aluminum arc plate is positioned at the top. The separation process leverages a composite electric field, combining corona and electrostatic fields, to differentiate materials based on conductivity. Conductive materials experience enhanced electrostatic attraction, while non-conductive materials encounter increased repulsion.

As the material mixture undergoes crushing and grinding, it enters the cylindrical separator through a feed funnel. The rotating cylinder exposes the material to the corona electric field generated between the high-voltage and grounding electrodes. Conductive particles, upon contact with the grounding electrode, acquire a charge and are subsequently ejected into the conductor particle receiving groove due to centrifugal and gravitational forces.

Non-conductive or weakly conductive particles exhibit difficulty transferring charges upon contact with the cylinder. These particles accumulate charges and adhere to the cylinder’s surface before being dislodged into the non-conductive particle receiving groove by the rotating brush.

Installation Guidelines

- Base Installation: The machine requires a vertical installation on a stable chassis.

- Grounding: Implement a robust grounding system by burying an angle iron or water pipe to a depth of 2-3 meters in a moist location.

- Cable Protection: Encase high-voltage cables within a plastic tube to prevent potential electrical leaks.

- Ore Storage Heating: Utilize a 4.5 square millimeter cable for ore storage heating, controlled by high and low-temperature switches within the control cabinet.

Improved Specification

- Advanced Design and Construction: Featuring a well-engineered structure and cutting-edge technology.

- User-Friendly and Safe: Designed for convenient operation with comprehensive safety features.

- High Automation and Reliability: Offers a high degree of automation, ensuring safe and dependable performance.

- Precise Separation: Capable of accurately separating minerals ranging from 120 mesh to 2mm.

- Comprehensive Functionality: Equipped with automated feeding, heating, speed control, and high-pressure discharge systems for enhanced efficiency and safety.

If you have ideas or questions about gold process plant and industrial processing equipment, please contact us: Whatsapp:+86 133 1927 7356

Email:[email protected]